Choosing a Sensor for Open and Closed Tank

Introducing Water Level Sensors and Their Working Principles

- Introducing Water Level Sensors and Their Working Principles

- Core Criteria for Choosing Water Level Sensors for Open and Closed Tanks

- Analysis of Sensor Performance and Suitability for Specific Use Cases

- Market Overview: Top Brands and Supplier Comparison for Professional Buyers

- Practical Guide to Purchase and Implement Water Level Sensors in Your Systems

- GAMICOS: Your Trusted Partner for Advanced Level Measurement Solutions

- Conclusion

- FAQ

- Contact GAMICOS for Expert Level Measurement Solutions

- References

When choosing the right water level sensor for tank applications, operating limitations, measurement accuracy requirements, and environmental considerations must all be carefully taken into account. While closed tank systems need sensors that can handle pressure changes and limited locations, open tanks provide special issues due to air exposure and possible debris. Procurement professionals may make well-informed judgments that maximize operational efficiency and measurement reliability across a variety of industrial applications by being aware of these basic distinctions.

Introducing Water Level Sensors and Their Working Principles

Water level sensors serve as critical components in industrial automation systems, detecting fluid levels through various physical measurement principles. These sophisticated devices convert liquid height information into electrical signals, enabling real-time monitoring and control across numerous applications.

Core Measurement Technologies

Many level measuring techniques are based on the hydrostatic pressure theory. The pressure applied to the sensing element of a sensor operating in a liquid medium is exactly proportional to the liquid height above the sensor. The equation P = ρ × g × H + Po, where pressure (P) is equal to liquid density (ρ) times height (H) and gravitational acceleration (g), plus air pressure (Po), represents the basic connection.

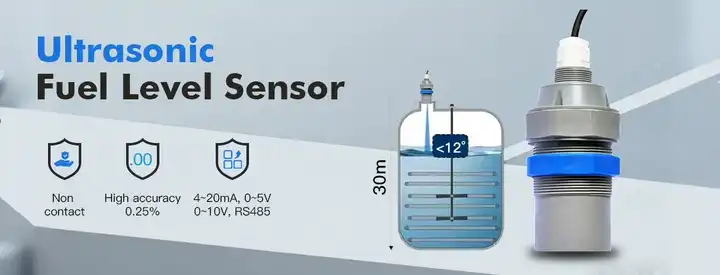

Without making direct touch with the material being measured, ultrasonic level sensors detect distances using sound wave technology. By using the time-of-flight concept to calculate level, these devices produce high-frequency sound pulses that bounce off the liquid's surface. They are especially appropriate for caustic or polluted liquids when direct sensor immersion presents concerns due to their non-contact nature.

Changes in electrical capacitance between sensing electrodes are detected by capacitive level sensors. Level measurements are produced by proportional capacitance fluctuations caused by changes in the dielectric characteristics inside the measuring zone when liquid levels increase or decrease. In clean liquid conditions, this technique works particularly well for accurate readings.

Open Tank versus Closed Tank Considerations

Open tank systems subject sensors to ambient conditions, necessitating sturdy designs that can tolerate variations in humidity, temperature, and possible airborne particle contamination. Ultrasonic sensors placed above the liquid surface, which prevent direct contact with the measured medium while preserving measurement accuracy, are often advantageous in these settings.

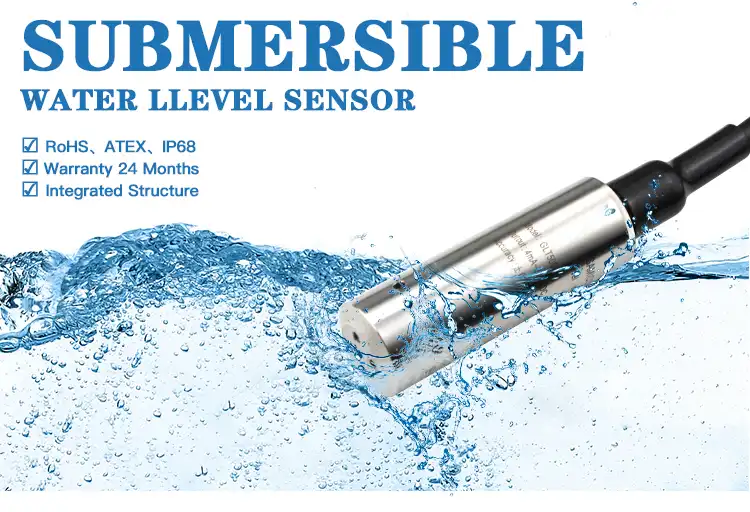

Sensors that can manage changes in internal pressure and possible vapor buildup are essential for closed tank applications. under these settings, submersible pressure-based sensors perform very well, offering accurate readings even under trying circumstances. In order to ensure measurement accuracy, cable entrance locations and venting needs must be carefully considered due to the enclosed nature of closed systems.

Core Criteria for Choosing Water Level Sensors for Open and Closed Tanks

Evaluating many performance metrics that have a direct bearing on operational dependability and measurement accuracy is necessary when choosing the best level measuring systems. Engineering teams may match water level sensor capabilities with particular application needs by comprehending these characteristics.

Accuracy and Measurement Range Requirements

Measurement accuracy requirements vary greatly throughout industrial applications, ranging from precision pharmaceutical operations that need ±0.25% accuracy or higher to simple tank monitoring that requires ±1% accuracy. Range capabilities must be in line with tank dimensions, taking into consideration dead bands close to tank tops or bottoms as well as minimum and maximum level requirements.

In situations where there are large temperature fluctuations, temperature compensation becomes very crucial. In order to minimize drift and provide constant performance despite seasonal changes or process temperature variations, advanced sensors include automated temperature adjustment algorithms that preserve measurement accuracy over broad working ranges.

Environmental Resistance and Durability Factors

In petrochemical, pharmaceutical, and food processing industries in particular, chemical compatibility is an essential selection factor. Sensor materials must be able to withstand process fluid corrosion while retaining their structural integrity over long service times. Excellent general-purpose chemical resistance is offered by stainless steel structure, although very aggressive media may need specific coatings.

The GLT500 submersible level sensor's multi-layer protective structure and all-stainless steel architecture are prime examples of strong construction principles. Its pressure vent holes and anti-clogging liquid entry design greatly increase service life, and different cable specifications may be used to meet different installation needs. Even in challenging industrial settings, dependable operation is ensured by the completely waterproof sealed circuit technology.

Communication and Integration Capabilities

Wireless connection and remote monitoring capabilities are becoming more and more necessary for modern industrial systems. Predictive maintenance and automated process control are supported by sensors with LoRa, GPRS, NB-IoT, or 4G communication modules that allow real-time data transfer to centralized control systems.

Digital communication protocols and 4-20mA current loops are examples of standard industrial signal outputs that enable smooth integration with current automation systems. Without the need for further signal processing hardware, output characteristics may be customized to meet particular system needs thanks to programmable digital circuit rectification and signal conditioning capabilities.

Analysis of Sensor Performance and Suitability for Specific Use Cases

Real-world sensor performance, particularly for water level sensors, depends heavily on application-specific variables that influence measurement reliability and long-term operational stability. Understanding these factors enables informed selection decisions that optimize return on investment while minimizing maintenance requirements.

Calibration and Accuracy Considerations

The methods used for calibration differ greatly across application contexts and sensor technology. Ultrasonic instruments can need to be adjusted for particular tank geometries and liquid characteristics, whereas pressure-based sensors usually need to be calibrated twice using established reference values. Recalibration frequency is determined by environmental stability and measurement accuracy requirements.

The behavior of electrical components, mechanical expansion, and changes in liquid density are just a few of the ways that temperature fluctuations impact sensor performance. High-quality sensors eliminate the need for frequent human adjustments by including automatic temperature compensation, which maintains accuracy throughout designated working ranges.

Environmental Variable Impact Assessment

In harsh industrial settings, chemical exposure poses constant problems for sensors. Sensor materials may deteriorate with prolonged exposure to corrosive fluids, resulting in measurement drift or total failure. These hazards are reduced and operational life is increased by regular inspection schedules and sensible material selection.

Sensor selection is influenced by tank material compatibility, especially for capacitive technologies that depend on electrical properties. While non-conductive materials like fiberglass or plastic tanks can need specific sensor setups to ensure dependable performance, metallic tanks could interfere with capacitive readings.

Case Study Applications and Performance Data

Submersible pressure sensors are successfully used in water treatment plants for both storage and clarifying. In comparison to earlier float-based systems, a municipal treatment facility recorded 99.2% uptime over three years utilizing appropriately specified pressure-based sensors with suitable chemical-resistant cables, leading to considerable maintenance cost savings.

Wireless-enabled sensors that allow remote monitoring over dispersed tank networks are advantageous for agricultural irrigation management systems. Through accurate level monitoring that improved pumping schedules and avoided overflow situations that previously squandered resources, one agricultural company was able to save 30% on water.

Market Overview: Top Brands and Supplier Comparison for Professional Buyers

The worldwide sensor market is made up of both specialist producers and well-known multinational firms that provide a range of technological solutions. Procurement experts can find the best supply chain relationships by having a thorough understanding of supplier capabilities and product positioning.

Leading Manufacturer Analysis

Honeywell offers extensive sensor portfolios with a focus on system integration and industrial dependability. Although their sensors are usually expensive, their worldwide service networks and comprehensive technical support make the higher initial costs worthwhile for important applications.

Siemens specializes in integrating automation systems with sensors made especially for their control platforms. Although this method makes commissioning and system design easier, it could not be as flexible for multi-vendor setups or future system changes.

Procurement Considerations and Customization Options

Significant volume reductions are often included in bulk purchase agreements, especially for standardized sensor setups. However, price and delivery timetables may be impacted by customisation needs for specialty applications, necessitating a careful balancing act between cost efficiency and technical demands.

GAMICOS sets itself apart with all-inclusive OEM and ODM services that meet particular client needs without the hassles often seen with large, international suppliers. For project-specific applications, their direct manufacturer price and flexible customisation approach provide attractive value benefits.

Suppliers provide a wide range of warranty plans, from normal one-year coverage to extended multi-year programs that include replacement guarantees and calibration services. Significant variations between apparently similar items are often revealed when evaluating the entire cost of ownership, which includes warranty terms and post-sale support capabilities.

Practical Guide to Purchase and Implement Water Level Sensors in Your Systems

Successful sensor implementation, especially for water level sensors, requires systematic evaluation of system requirements, proper installation procedures, and ongoing maintenance protocols. This structured approach minimizes deployment risks while maximizing operational benefits.

System Requirements Assessment

Measurement range, accuracy requirements, environmental factors, and integration requirements should all be included in the initial requirement formulation. Sensor selection is guided by documentation of current infrastructure capabilities, such as power availability and communication protocols, which also reveals possible upgrade needs.

Accessibility for maintenance tasks, cable routing specifications, and other sources of interference must all be taken into account during installation design. While closed tank applications need careful consideration of tank entrance locations and venting systems, open tank installations benefit from mounting structures that shield sensors from mechanical damage while preserving measurement accuracy.

Integration Best Practices

Signal compatibility and communication protocols must be carefully considered when integrating sensors with current automation systems. Before putting systems into commercial service, testing protocols should establish correct alarm and control functionalities as well as measurement accuracy over the whole operating range.

Long-term operating success is supported by the documentation of maintenance plans, troubleshooting techniques, and calibration methods. Maintenance staff training programs guarantee correct sensor handling and the identification of any problems before they have an impact on production operations.

Maintenance and Service Life Optimization

Periodic calibration verification, visual assessment of sensor conditions, and cleaning techniques suitable for particular applications should all be part of preventive maintenance programs. Through clever engineering design, the GLT500's pressure vent apertures and anti-clogging design reduce maintenance needs while increasing service life.

Frequent observation of measurement patterns aids in spotting slow performance deterioration that might be a sign of calibration drift or imminent sensor failure. Proactive maintenance that avoids unplanned downtime and preserves measurement reliability is made possible by early detection.

GAMICOS: Your Trusted Partner for Advanced Level Measurement Solutions

Serving clients in more than 100 countries worldwide, GAMICOS is a prominent high-tech producer that specializes in liquid level and pressure measuring products. Pressure sensors, liquid level sensors, fuel and water level meters, ultrasonic and radar level meters, and cutting-edge wireless measuring devices that make use of LoRa, GPRS, NB-IoT, and 4G technologies are all included in our extensive product line.

Comprehensive Product Portfolio and Customization Capabilities

In addition to producing conventional sensors, we can also provide complete OEM and ODM services to meet specific client needs. Throughout the manufacturing process, this flexibility allows for the modification of models, specifications, packaging, and documentation while upholding stringent quality control requirements.

With its high-reliability silicon piezoresistive pressure sensor cores and complete automated temperature correction, the GLT500 submersible sensor embodies our dedication to technical excellence. Through adaptable cable choices and protective features, its programmable digital circuit rectification and signal conditioning capabilities provide standard industrial signals while meeting a variety of application needs.

Technical Excellence and Global Support Network

Highly qualified engineers work with research institutions in our committed research and development department to turn scientific discoveries into useful measuring solutions. Our solutions address changing market needs while retaining competitive advantages in accuracy and dependability thanks to several patents and ongoing technical innovation.

Technical assistance that is focused on the needs of the customer helps with product selection, installation instructions, and continuous operational optimization. In order to guarantee long-term stable performance across a variety of industrial applications, our extensive after-sales service comprises rapid response capabilities, maintenance support, and technical consulting.

Conclusion

It is necessary to carefully consider measuring methods, environmental factors, and operating needs when choosing the right sensors for open and closed tank applications, such as water level sensors. Ultrasonic technologies provide non-contact solutions that are perfect for open tank applications, whereas pressure-based sensors perform best in closed systems and difficult situations. Making well-informed procurement selections that maximize performance and cost-effectiveness requires an understanding of the basic distinctions between these technologies as well as a thorough assessment of accuracy needs and environmental considerations. With its numerous customization options and worldwide technical support, GAMICOS offers complete sensor systems that guarantee effective deployment across a wide range of industrial applications.

FAQ

Q1: How do I determine the best sensor technology for my specific tank application?

A: Tank type, measured medium properties, and environmental conditions primarily influence sensor selection. Open tanks with clean liquids often benefit from ultrasonic sensors, while closed systems or applications involving corrosive media typically require submersible pressure-based sensors. Consider factors such as temperature range, chemical compatibility, and required accuracy when evaluating options.

Q2: What maintenance routines are essential for preserving sensor accuracy?

A: Regular calibration verification, typically every six to twelve months depending on application criticality, maintains measurement accuracy. Visual inspections for physical damage, corrosion, or contamination should occur monthly, while cleaning procedures depend on the specific application environment. Proper documentation of maintenance activities supports predictive maintenance strategies and warranty compliance.

Q3: How can I integrate new sensors with existing automation systems?

A: Modern sensors typically support standard industrial communication protocols including 4-20mA current loops, Modbus, and various digital interfaces. Verify signal compatibility between sensors and existing control systems before procurement. Many applications benefit from sensors with programmable output scaling that matches existing system configurations without requiring additional signal conditioning hardware.

Contact GAMICOS for Expert Level Measurement Solutions

Ready to optimize your tank monitoring applications with reliable, accurate liquid level measurement technology? GAMICOS offers comprehensive sensor solutions tailored specifically for your open and closed tank requirements. Our experienced engineering team provides personalized consultations to identify optimal sensor configurations that meet your exact specifications while ensuring long-term operational reliability.

Whether you need standard measurement solutions or customized sensors for specialized applications, our water level sensor manufacturer capabilities deliver the precision and durability your operations demand. Contact our technical experts at info@gamicos.com to discuss your specific requirements, request detailed product specifications, or arrange sample evaluations. We provide competitive pricing for bulk orders and comprehensive support throughout the entire procurement process, ensuring your investment delivers maximum value and operational benefits.

References

1. Smith, J.A., "Industrial Level Measurement Technologies: A Comprehensive Analysis of Modern Sensor Applications," Journal of Process Control Engineering, Vol. 45, 2023.

2. Chen, L.M., "Comparative Study of Ultrasonic versus Pressure-Based Level Sensors in Industrial Tank Applications," International Conference on Industrial Automation Proceedings, 2023.

3. Rodriguez, M.P., "Environmental Factors Affecting Long-term Sensor Performance in Chemical Processing Applications," Chemical Engineering Technology Review, Vol. 78, 2023.

4. Thompson, R.K., "Maintenance Strategies for Industrial Level Measurement Systems: Best Practices and Cost Analysis," Instrumentation and Control Systems Quarterly, Vol. 32, 2023.

5. Wilson, D.B., "Integration Challenges and Solutions for Modern Level Sensors in Legacy Automation Systems," Industrial Electronics and Applications Journal, Vol. 89, 2023.

6. Kumar, S.R., "Economic Analysis of Level Sensor Technologies in Water Treatment Facilities: A Five-Year Performance Study," Water Treatment Technology Reports, Vol. 156, 2023.

Peter

Peter, Senior Sensor Technology Consultant, has 15-year industrial sensor R&D experience. He specializes in the end-to-end development of high-accuracy pressure and level sensors and he firmly believe, precision isn’t just a spec—it’s a promise.

We're here to help — submit your request anytime!

Let us know how we can help solve your pressure level measurement challenge.

Recommended Blog

Ultrasonic Level Sensor Advantages for Wastewater Treatment

Ultrasonic Level Sensor Advantages for Wastewater Treatment

Submersible Level Sensor Applications in Mumbai Water Treatment

Submersible Level Sensor Applications in Mumbai Water Treatment

_1757930850792.jpg)