It isn't easy to find trustworthy sources for liquid level sensors. You need to think about area markets, what suppliers can do, and quality standards. Procurement workers have different benefits in the Americas, Europe, and Asia. North American suppliers are great at advanced technology and customer service, European makers offer strict quality certifications, and Asian companies offer strong manufacturing skills at low prices. Engineering managers, sourcing professionals, and project managers who know about these regional strengths are better able to make smart buying choices that fit their specific needs in industrial automation.

Why Global Sourcing of Liquid Level Measurement Solutions Matters?

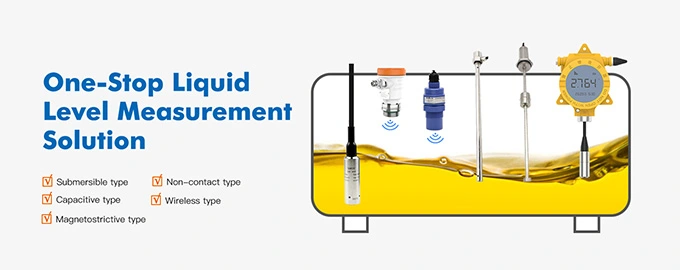

These days, factories need to be able to precisely measure liquid levels for all sorts of purposes. Global sourcing gives businesses access to specialized technologies, competitive pricing, and new ways of doing things that are tailored to the needs of their market.

Strategic Advantages of International Procurement

By buying internationally, you can get the newest sensor technologies that have been created in a variety of areas. When it comes to IoT connectivity and wireless sensor networks, American businesses are often the ones in charge. When it comes to safety standards for dangerous settings, European makers really know their stuff. Asian suppliers offer a lot of different ways to save money and make things just the way you want them.

Regional specialization gives sourcing managers more chances to find the best suppliers for each unique technical need. Oil companies benefit from explosion-proof sensors that were made in areas with very strict safety rules. Clean sensors that meet global health standards can be found by food and drink companies.

Overcoming Global Sourcing Challenges

When you buy things from other countries, you need to make sure of the quality, communicate clearly, and coordinate the procedures. It is easier to stay safe on a project when you set clear technical specs, certification standards, and delivery dates.

When getting goods from sources that are far away, quality assurance is very important. Third-party certifications, thorough testing, and sample review programs make sure that products are reliable. A lot of companies that do industrial automation use supplier audit programs to check on their manufacturing skills and quality systems.

Regional Market Analysis: Americas, Europe, and Asia

Each part of the world has its own market features, supply skills, and areas of technological strength that affect sourcing choices.

Americas Market Dynamics

Suppliers in North America focus on high-performance liquid level sensors that have new ways of communicating digitally. Businesses in this area are great at making IoT-enabled gadgets that help with Industry 4.0 projects. New wireless sensor networks and predictive repair technologies are made possible by strong research and development teams.

The US market stresses safety and legal compliance for chemicals, drugs, and petroleum. Canadian suppliers often focus on making sensors for use in very hot or very cold conditions, using their knowledge from working in oil sands and arctic activities.

European Excellence in Quality and Standards

European makers follow strict international rules like CE marking, the RoHS directive, and ISO certifications. When it comes to precision building and long-term reliability for important uses, German and Swiss businesses are the best.

The European market for explosion-proof sensors and hazardous area certifications shows a lot of power. Innovations in safe designs that work for chemical processing and offshore uses have been made because of the need to follow ATEX compliance rules.

Asian Manufacturing Capabilities

Suppliers in Asia, especially those in China, can make a lot of products and offer good prices. These businesses are great at OEM/ODM services, which means they make products according to other companies' designs and specifications.

Chinese makers show great willingness to customize products to meet different interface needs, communication protocols, and physical setups. GAMICOS is an example of a company that can do this because it gives unique measurement solutions to customers in over 100 countries.

Comparing Sourcing Channels and Procurement Methods

It is best to get things from different places based on the needs of the project, the amount of the order, and the need for technical support.

Regional Distributor Networks

Local distributors offer quick access and technical help in the area. These partners keep a stock of popular liquid level sensor types on hand so that they can be quickly delivered for maintenance and replacement.

For businesses that need technical support and help with applications all the time, having good ties with distributors is important. Regional partners know the rules in their areas and can help you follow the rules in your market.

B2B Platform Considerations

Online B2B platforms make it easier to find suppliers and do market study. These tools make it easy to compare several different vendors' specifications, prices, and capabilities.

Successful B2B platforms require factory exams, quality certifications, and reference checks to make sure suppliers are legit. Before getting to know their suppliers, a lot of procurement teams use these platforms to do their first study.

Practical Sourcing Guidelines and Best Practices

When you want to find a good liquid level measurement provider, you need to have a plan for looking at suppliers, checking quality, and managing risk.

Supplier Screening and Verification Process

The first step in a thorough supplier review is to look at their technical capabilities. Look over the ways that quality is controlled, output capabilities, and manufacturing certifications. Ask for customer references, test reports, and thorough product information.

Financial stability verification makes sure that sellers can keep their promises for a long time. Audited financial statements and credit reports are needed by many businesses in order to have a meaningful partnership with a supplier. Visits to production facilities help people understand how things are made and how quality is checked.

Quality Control and Testing Protocols

Set clear standards for how much measurement accuracy, environmental specifications, and dependability are acceptable. For important applications, ask for performance test results and calibration certificates.

Sample testing programs check that the liquid level sensors work under situations that are similar to how they are actually used. Many businesses use incoming inspection procedures and periodic audit testing to make sure that the quality standards are met during the entire relationship with the provider.

Commercial Terms and Risk Management

Suppliers and product types differ greatly in minimum order numbers. The minimum order quantity (MOQ) for standard sensors is usually 10 to 50 pieces, but for personalized solutions, it is typically 100 to 500 pieces. New sellers usually have to pay 30% up front and the rest before shipping.

It takes anywhere from 1 to 2 weeks for standard goods to 4 to 8 weeks for custom products to be delivered. International shipping takes an extra 1 to 3 weeks, based on where it's going and how it's being shipped. A lot of businesses keep safety stock on hand to deal with sudden changes in demand.

Conclusion

When you want to buy a liquid level sensor, you need to know the pros and cons of the market in your area, what the suppliers can do, and the technical needs of the sensors. The Americas are great at using new technologies, Europe gives better quality certifications, and Asia has competitive manufacturing with a lot of customization. Direct factory buying works well for big needs, while distributor networks serve short-term needs. A method for quality control, clear technical specs, and careful verification of suppliers all help get the best procurement results. To get the most flexibility in sourcing and avoid risk, companies should build ties with a lot of suppliers in different areas.

Frequently Asked Questions

Q1: What makes people choose between capacitive and ultrasonic liquid level sensors?

A: How the sensor is used affects the choice of sensor. Capacitive sensors are great for measuring with high accuracy when they are directly touched, but ultrasonic sensors are better for measuring media that are corrosive or for uses that require non-contact measurement. When choosing a sensor technology, think about things like the media it will be in, how the tank will be set up, how accurate it needs to be, and how easy it is to maintain.

Q2: How can businesses be sure that their overseas sources are good?

A: Do full verification with plant checks, quality certification reviews, customer references, and testing programs for samples. ISO certifications, calibration records, and performance test data should be asked for. A lot of great businesses check the work of their suppliers and meet with them in person.

Q3: How long does it usually take to get custom-made liquid level measurement solutions?

A: Made-to-order sensors usually take between 4 and 8 weeks to make, plus time to ship. It can take anywhere from 2 to 4 weeks to a few months to make the changes that are needed, depending on how simple or complex they are. For example, changing the connection is a simple modification that takes 2 to 4 weeks, but changing the probe design is a more complex customization that takes even longer. Standard goods usually come from well-known suppliers within 1–2 weeks.

Partner with GAMICOS for Your Liquid Level Measurement Needs

GAMICOS is a top maker of liquid level sensors, providing accurate measuring tools to businesses across six countries. Our wide range of products includes capacitive, ultrasonic, and radar level sensors made for tough jobs in the petroleum, chemical, pharmaceutical, and food processing industries. Our tech team offers a lot of customization options, such as sensor sizes, communication methods, and certification standards. Our supply chains are reliable, and we use factories that are set up for high-volume output and strict quality control to support OEM partners and industrial end-users.

With GAMICOS, you get the benefit of our focused tech help, extensive testing labs, and shipping networks across the world. Our sensors keep the precision standards below 1mm resolution and perform well over time in difficult settings. Ready to talk about what you need? For personalized technical help and good prices on your next job, email us at info@gamicos.com.

References

1. Industrial Automation and Control Systems Global Market Report 2023, Research and Markets Ltd.

2. Liquid Level Sensors Market Analysis and Forecast 2022-2027, TechNavio Research.

3. Process Instrumentation Market Trends in Chemical and Petrochemical Industries, Frost & Sullivan.

4. International Standards for Level Measurement Instrumentation, International Society of Automation.

5. Supply Chain Management Best Practices in Industrial Equipment Procurement, Manufacturing Engineering Society.

6. Sensor Technology Advances in Industrial IoT Applications, IEEE Industrial Electronics Magazine.

_1757930850792.jpg)