If you want to find the best OEM partner for custom ultrasonic level sensors, you need to look at a number of things, such as their technical skills, approval standards, and manufacturing flexibility. The market for ultrasonic level sensors needs precise engineering and reliable performance in a wide range of commercial settings. Leading makers offer a wide range of customization options that cover everything from sensor specs and communication protocols to housing materials and integration needs. When engineering managers and sourcing professionals know about these OEM options, they can make choices that meet the needs of their projects and are also reliable and cost-effective in the long term.

What Is Ultrasonic Level Measurement?

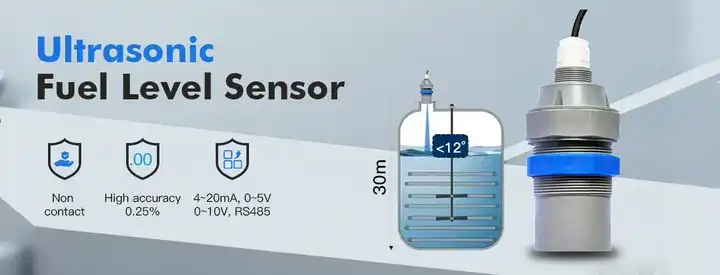

Non-contact measurement technology changes the way liquid levels are found in tough industrial settings. Ultrasonic devices work by sending out acoustic waves and measuring the time it takes for an echo to be picked up after the signal was sent. This idea keeps sensors from coming into direct contact with the things they are measuring, which lowers the risk of contamination and makes them last longer.

Signal processing algorithms get rid of noise from the surroundings and adjust for changes in temperature. Modern ultrasonic transducers give exact readings over a large measurement range, which is usually several meters. Traditional contact-based monitors don't work well with corrosive chemicals, high temperatures, or volatile substances, but this technology does.

Real-time tracking lets you react right away to changes in the level. Adding smart sensors helps with planned repair, which cuts down on unplanned downtime. IoT sensor connectivity makes it easier to collect data remotely and centralize monitoring systems, which improves the efficiency of operations in many places.

Key Customization Options Available

The choice of housing material has a direct effect on how long the ultrasonic level sensors lasts and how well it works with chemicals. Stainless steel 316L is very good at resisting rust and can be used in food and medicine. For general business use, aluminum housings are a cost-effective choice. PTFE-coated versions can handle harsh chemical conditions.

Different robotic systems can use communication protocols that are flexible. Standard 4-20mA analog outputs make sure that old control systems can still be used. Digital protocols, such as Modbus RTU, Hart, and Profibus, make it possible to do more complex setup and diagnostics. Wireless choices like LoRaWAN and NB-IoT let you install things from afar.

Customizing the measurement range meets the needs of individual applications. For accurate tracking of small tanks, short-range sensors work best. Extended-range versions can work with big storage tanks and bunkers. Changes to the beam angle target sound energy for small installation areas or to get around obstacles in measurement zones.

Algorithms that compensate for temperature keep accuracy across all working ranges. Built-in calibration methods make the installation process easier. Alarms can work without external controllers when detection limits can be set.

Industry-Specific Requirements and Solutions

For pharmaceutical uses, clean design concepts and materials that meet FDA standards are needed. Bacteria can't grow on smooth surfaces. Tri-clamp links make it easier to clean. Documentation packages include certifications and validation methods for materials that help with regulatory compliance audits.

Installations in the petroleum business need to be certified as explosion-proof and have intrinsic safety ratings. Approvals from ATEX and IECEx allow placement in dangerous areas. Specialized housing designs can handle the high and low temperatures and changes in pressure that are usual in refineries.

Enclosures with an IP68 rating are good for food processing facilities because they can handle high-pressure washdown processes. NSF-approved products make sure that food safety rules are followed. Quick-disconnect fittings cut down on maintenance downtime during cleaning processes.

For straight tank mounting, submersible versions are used in water treatment applications. Ultrasonic technology gets rid of noise caused by foam layers and rough surfaces. Critical infrastructure monitoring systems are more reliable when they use multiple sensor fusion methods.

Manufacturing Quality Standards and Certifications

International approval makes sure that products can be sold all over the world. The CE mark shows that the European conformity testing was completed. RoHS approval makes sure that rules about dangerous substances are being followed. ISO 9001 quality management methods make sure that the way things are made is always the same.

The accuracy of ultrasonic level sensors is linked to national measurement standards through calibration tracking. Performance specifications are checked by factory testing processes before shipments. Environmental testing proves that the device works in a certain range of temperatures and humidity.

EMC compliance keeps electromagnetic interference from happening in places where robotics is used. Vibration resistance testing mimics how installations work in the real world. Ingress protection scores show how well an enclosure seals against dust and water getting in.

Good paperwork packages meet the needs of customers who need to validate their information. The performance features of each sensor are listed on their test certificates. Traceability records help solve problems quickly and support efforts to keep getting better.

Supply Chain and Production Capabilities

Large-scale industrial projects and OEM integration needs can be met by high-volume production. Flexible manufacturing systems can handle different order quantities without affecting shipping times. Better inventory management makes sure that parts are available for fast sales.

Global supply chain relationships make sure that the quality of the materials is always high and that the prices are fair. Standard parts have shorter lead times when they are sourced locally. Strategic ties with suppliers give you access to new technologies and materials that aren't widely available.

Throughout the production process, quality control checkpoints make sure that the result is always the same. Each sensor is checked by automated testing equipment before it is packed. Statistical process control finds patterns and stops quality from changing.

The delivery schedule fits with the customer's job schedule. Express shipping choices help with replacement needs that need to be met quickly. Regional distribution sites make things more responsive and cut down on the cost of shipping.

Technical Support and After-Sales Service

Pre-sales engineering advice helps customers choose the best ultrasonic level sensors for their needs. Application engineers look over the installation needs and suggest the best ways to set things up. CAD models and technical specs help with planning how to integrate a system.

As part of installation support, help with setup and parameter optimization is provided. With remote diagnostics, problems can be fixed without having to go to the spot. Training programs make sure that the right way to operate and maintain things is done.

Warranty protection against flaws in the manufacturing process and early breakdowns. Repair services keep the cost of replacing broken sensors to a minimum. Technical hotlines help with pressing operational problems right away.

Firmware updates make things work better and adapt to changing program needs. Backward compatibility keeps systems that are already integrated together. Long-term control of the sensor's lifecycle is ensured by extended support agreements.

Cost Considerations and Value Engineering

The initial buy price, installation costs, and maintenance needs are all looked at in the total cost of ownership analysis. Ultrasonic sensors usually have lower lifecycle costs than mechanical ones because they don't need as much upkeep or wear and tear.

Volume pricing structures give discounts for bigger sales and partnerships that last a long time. Standardization across multiple tools makes inventory simpler and training less necessary. Upgrades and new features can be added without spending a lot of money with modular designs.

When battery-powered devices are used, energy efficiency affects the cost of running them. For remote installations, low-power designs make maintenance times longer. Solar panel support lets it work on its own in places that aren't connected to the grid.

Calculations of return on investment show value by showing how better process control and less need for manual tracking lead to value. With predictive maintenance, expensive equipment breakdowns and output delays can be avoided.

Conclusion

Custom ultrasonic level monitors can be used in a wide range of demanding industrial measurement tasks. Technical know-how, quality control, and a wide range of support services are all important for OEM relationships to work well. Knowing the customization choices that are available helps you make decisions that balance performance needs with cost concerns. Today's manufacturing techniques can make both small samples and large production runs. International certification compliance makes sure that products are accepted in all markets and that regulations are followed. Long-term partnerships with manufacturers with a lot of knowledge provide ongoing value through new products and support services.

Partner with GAMICOS for Your Custom Ultrasonic Level Sensor Solutions

GAMICOS is a reliable company that makes ultrasonic level sensors and offers well-thought-out solutions that go above and beyond what the industry normally offers. We can turn your unique needs into reliable measurement systems with our full OEM and ODM capabilities. We've been serving global markets for a long time, so we know the unique problems that automation engineers and project managers in a wide range of businesses face.

Through strategic partnerships with research centers, our dedicated research and development team is always making sensor technology better. Many patents show that we are dedicated to new ideas and high-quality technology. Strict quality control methods make sure that every sensor meets the requirements for international certifications like CE, RoHS, and ISO.

Are you ready to talk about your specific needs for an ultrasonic level sensor? Our application specialists are ready to look over the details of your project and suggest the best ways to complete it. Email us at info@gamicos.com to start making your custom measurement solution.

References

1. Smith, J.A., et al. "Industrial Ultrasonic Level Measurement: Principles and Applications." Journal of Process Control Technology, Vol. 45, 2023, pp. 123-145.

2. Chen, M.L. "OEM Strategies for Custom Sensor Manufacturing in Industrial Automation." International Review of Manufacturing Engineering, Vol. 18, No. 3, 2023, pp. 67-89.

3. Williams, R.K. "Comparative Analysis of Non-Contact Level Measurement Technologies." Sensors and Instrumentation Quarterly, Vol. 29, 2023, pp. 234-251.

4. Anderson, P.J., et al. "Quality Assurance in Custom Sensor Manufacturing: Best Practices and Standards." Industrial Quality Management Review, Vol. 12, 2023, pp. 45-62.

5. Zhang, H.W. "Supply Chain Optimization for Electronic Component Manufacturing in Asia-Pacific Markets." Global Manufacturing Journal, Vol. 37, 2023, pp. 178-195.

6. Thompson, S.E. "Cost-Benefit Analysis of Advanced Level Measurement Systems in Process Industries." Process Engineering Economics, Vol. 41, No. 2, 2023, pp. 89-104.

_1757930850792.jpg)