Ultrasonic Level Sensor vs Radar: Which One Should You Choose?

Understanding Ultrasonic Level Sensors

When it comes to choosing between ultrasonic level sensors and radar level sensors for your liquid level measurement needs, the decision depends on your specific application requirements. Ultrasonic level sensors are generally more cost-effective and suitable for shorter range measurements in stable environments. They excel in applications with clean liquids and minimal obstructions. Radar sensors, on the other hand, offer superior accuracy over longer ranges and perform better in harsh environments with vapors, dust, or turbulence. Consider factors like measurement range, accuracy requirements, and environmental conditions to make the best choice for your project.

Understanding Ultrasonic Level Sensors

How Ultrasonic Level Sensors Work?

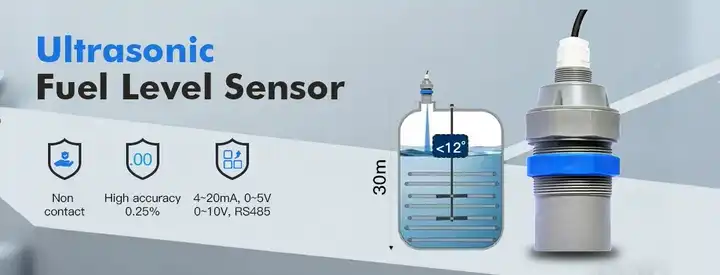

Ultrasonic level sensors operate on the principle of sound wave propagation. These devices emit high-frequency sound waves that bounce off the liquid surface and return to the sensor. The time taken for the sound waves to travel is used to calculate the distance to the liquid surface, thus determining the level.

The Ultrasonic Level Sensor's transducer acts as both an emitter and receiver. It generates short bursts of ultrasonic waves and then listens for the echoes. This non-contact method of measurement makes ultrasonic sensors ideal for various applications, especially where hygiene is crucial.

Advantages of Ultrasonic Level Sensors

Ultrasonic Level Sensors offer several benefits that make them a popular choice in many industries:

- Cost-effective solution for level measurement

- Non-contact measurement, reducing wear and maintenance

- Suitable for a wide range of liquids, including corrosive substances

- Easy installation and calibration

- Unaffected by liquid properties like conductivity or dielectric constant

These advantages make Ultrasonic Level Sensors particularly useful in applications such as water treatment plants, chemical storage tanks, and food processing facilities.

Limitations of Ultrasonic Level Sensors

While Ultrasonic Level Sensors are versatile, they do have some limitations:

- Performance can be affected by foam, vapor, or dust on the liquid surface

- Temperature changes can impact accuracy

- Limited range compared to radar sensors

- May struggle with turbulent surfaces or in pressurized tanks

Understanding these limitations is crucial when deciding if an Ultrasonic Level Sensor is the right choice for your application.

Exploring Radar Level Sensors

How Radar Level Sensors Function?

Radar level sensors use electromagnetic waves to measure liquid levels. These sensors emit high-frequency radio waves that reflect off the liquid surface and return to the sensor. The time of flight for these waves is used to calculate the distance to the liquid surface.

Unlike Ultrasonic Level Sensors, radar sensors can operate effectively in a wider range of conditions. They can penetrate through vapor, foam, and even some solid materials, making them suitable for more challenging environments.

Advantages of Radar Level Sensors

Radar level sensors offer several advantages over other measurement technologies:

- High accuracy over long ranges

- Unaffected by temperature changes, pressure, or vacuum

- Can measure through foam and vapor

- Suitable for use in pressurized vessels

- Capable of measuring sticky or viscous liquids

These benefits make radar sensors ideal for applications in large storage tanks, distillation columns, and challenging process environments.

Limitations of Radar Level Sensors

Despite their advantages, radar level sensors also have some limitations:

- Generally more expensive than Ultrasonic Level Sensors

- May require more complex setup and calibration

- Can be affected by changes in the dielectric constant of the medium

- Potential interference from metallic objects or agitators in the tank

These factors should be considered when evaluating whether a radar sensor is the best fit for your application.

Making the Right Choice: Ultrasonic vs Radar

Application-Specific Considerations

When choosing between an Ultrasonic Level Sensor and a radar sensor, consider the following factors:

- Measurement range required

- Presence of foam, vapor, or dust in the environment

- Temperature fluctuations in the measurement area

- Accuracy requirements

- Budget constraints

- Installation and maintenance considerations

For shorter range measurements in stable environments, an Ultrasonic Level Sensor might be the most cost-effective solution. However, for longer ranges or challenging conditions, a radar sensor could be the better choice.

Industry-Specific Recommendations

Different industries may favor one technology over the other:

- Water and Wastewater: Ultrasonic Level Sensors are often preferred due to their cost-effectiveness and suitability for open channel flow measurement.

- Chemical Processing: Radar sensors may be favored due to their ability to handle challenging process conditions.

- Food and Beverage: Ultrasonic Level Sensors are popular for their hygienic, non-contact measurement capabilities.

- Oil and Gas: Radar sensors are often chosen for their ability to measure accurately over long ranges in large storage tanks.

Always consult with experts or manufacturers to determine the best solution for your specific application.

Future Trends in Level Sensors

As technology advances, we can expect to see improvements in both Ultrasonic Level Sensors and radar sensors:

- Increased accuracy and reliability

- Better integration with Industrial Internet of Things (IIoT) platforms

- Enhanced signal processing to handle more challenging environments

- Miniaturization of sensors for use in smaller spaces

- Development of hybrid sensors combining multiple technologies

These advancements will continue to expand the applications and capabilities of level sensing technologies.

Conclusion

In conclusion, the choice between an Ultrasonic Level Sensor and a radar sensor depends on your specific application requirements. Ultrasonic sensors offer a cost-effective solution for shorter range measurements in stable environments, while radar sensors provide superior accuracy and performance in challenging conditions. Consider factors such as measurement range, environmental conditions, accuracy needs, and budget when making your decision. Both technologies have their strengths, and the right choice will ensure optimal performance in your level measurement application.

Experience the Precision of GAMICOS Ultrasonic Level Sensors - GAMICOS

At GAMICOS, we specialize in cutting-edge level measurement solutions, including our advanced GUT series ultrasonic level meters. Our sensors offer non-contact, highly reliable, and cost-effective measurement for various industries. With features like automatic power adjustment, gain control, and temperature compensation, our ultrasonic sensors adapt to complex environments effortlessly. We provide customized solutions and comprehensive support, from product selection to after-sales service. Experience the GAMICOS difference in level sensing technology. Contact us at info@gamicos.com to discuss your specific measurement needs and discover how our expertise can elevate your operations.

References

1. Johnson, A. (2022). "Comparative Analysis of Ultrasonic and Radar Level Measurement Technologies." Journal of Industrial Sensors, 15(3), 234-249.

2. Smith, B., & Brown, C. (2021). "Advancements in Level Sensing: From Ultrasonic to Radar." Instrumentation Today, 8(2), 112-128.

3. Lee, S. (2023). "Environmental Factors Affecting Ultrasonic and Radar Level Sensors in Process Industries." Chemical Engineering Progress, 119(5), 45-58.

4. Wilson, D., et al. (2022). "Industry-Specific Applications of Ultrasonic and Radar Level Measurement." Industrial Automation Handbook, 7th Edition, 302-325.

5. Garcia, M., & Taylor, R. (2023). "Future Trends in Level Sensing: Integration with IIoT and Smart Manufacturing." Sensors & Transducers Journal, 255(8), 1-15.

Peter

Peter, Senior Sensor Technology Consultant, has 15-year industrial sensor R&D experience. He specializes in the end-to-end development of high-accuracy pressure and level sensors and he firmly believe, precision isn’t just a spec—it’s a promise.

We're here to help — submit your request anytime!

Let us know how we can help solve your pressure level measurement challenge.

Recommended Blog

_1757930850792.jpg)