Radar Level Transmitter Manufacturer for Custom Projects

Understanding Radar Level Transmitters

- Understanding Radar Level Transmitters

- How to Choose the Best Radar Level Transmitter for Your Custom Project?

- Advantages of Partnering with a Radar Level Transmitter Manufacturer for Custom Projects

- Procurement Guide: How to Buy Radar Level Transmitters for Bulk or Custom Orders?

- Conclusion

- FAQ

- Partner with GAMICOS for Advanced Radar Level Measurement Solutions

- References

Industrial workers need partners who understand difficult measurement problems when they are looking for a trusted Radar Level Transmitter maker for custom projects. Custom radar level solutions are made to meet specific operational needs that standard goods can't, especially in specialist fields like energy production, petrochemicals, and pharmaceuticals. These high-tech measuring tools use electromagnetic wave technology to provide very accurate level tracking without touching the level. Working with experienced makers guarantees the best performance through custom sensor layouts, high-tech materials, and communication methods made for specific uses.

Understanding Radar Level Transmitters

Radar level measurement technology is based on the idea that electromagnetic waves can be reflected, which makes it more accurate than other measurement methods. The technology sends microwave signals toward the surface of the medium being measured. When the signals are reflected back to the emitter antenna, the time-of-flight concept is used to figure out the distance.

Operating Principles and Advanced Technology

Radar level transmitters today use complex signal processing methods to make measurements that are incredibly accurate. Using 80GHz Frequency Modulated Continuous Wave (FMCW) radar technology, the GAMICOS GLT74 line is a great example of cutting edge technology. When the antenna is working, it sends out high-frequency FMCW signals whose frequencies rise in a straight line. The signal that is sent bounces off of solid or liquid objects and comes back to the same receiver. The goal distance stays related to the frequency difference between signals that are sent and signals that are received. The system figures out the target's distance very exactly by using Fast Fourier Transform (FFT) to look at frequency difference data.

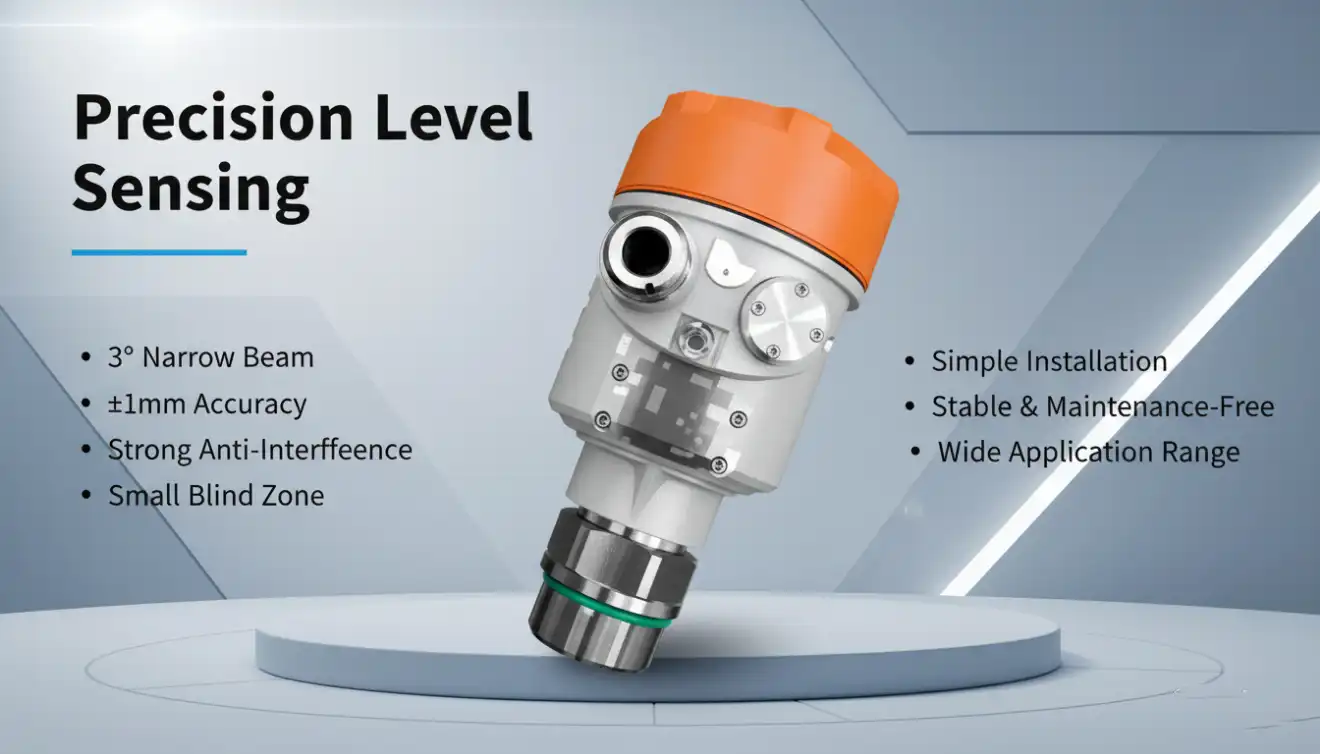

This advanced approach has a number of important benefits for use in industry. The frequency band of 80GHz is very good at blocking interference because it operates in a pretty clean electromagnetic spectrum space with few typical interference effects. The narrow beam angle of about 3° in both the horizontal and vertical directions makes sure that measurement zones are focused, which cuts down on false echoes from the tank walls or other structures inside the tank.

Primary Types of Radar Level Measurement Systems

Different radar level transmitter setups are useful for industrial uses because each one is best for a certain type of measurement. Knowing about these different kinds helps buying managers choose the best options for their business needs.

Guided wave radar receivers use physical probes to send electromagnetic waves in a way that follows a plan. When working with rough surfaces or materials that don't have a high dielectric constant, these methods work really well. The probe sends radio waves straight into the process media, making sure that signals can be sent and received reliably even in tough situations. When differences in dielectric constants are bigger than certain limits, interface testing tools can find more than one layer of liquid.

Using antennas to send and receive signals, non-contact radar devices work without touching the things they are measuring. These receivers usually work at 26GHz or higher frequencies, and they work very well in harsh settings where probe-based systems might not work as well. The GLT74 series 80GHz technology is the most advanced non-contact measurement method available. It can measure with a blind spot as close as 0.05m from the antenna and an accuracy of up to 1mm.

Industrial Applications Across Multiple Sectors

Radar level technology is used in many different types of industries. Each one has its own measurement problems that need unique answers. Sensors in chemical processing plants need to be able to deal with toxic materials, high temperatures, and volatile substances. Oil companies need reliable measurement tools that can work in explosive environments and have the right safety standards.

The food and drink businesses need sensor designs that are clean and meet strict cleanliness standards while still being accurate. When making medicines, they need to be carefully inspected at every step and backed up by proof that the process is working properly. Reliable measurement methods that work well with changing water quality and chemical additives are helpful for water treatment plants.

In tough industrial settings, radar technology clearly shows that it works better than options like ultrasound, capacitance, or pressure-based systems. Temperature changes, changes in pressure, the presence of gas, or the formation of foam don't affect radar systems in the same way that they do other measurement technologies.

How to Choose the Best Radar Level Transmitter for Your Custom Project?

To choose the best radar level measurement options, you need to carefully look at the performance standards, environmental factors, and operational needs. Professional methods to buying guarantee long-term dependability while lowering the total cost of ownership.

Defining Measurement Scenarios and Requirements

To choose a good radar level transmitter, you must first carefully look at all the possible measurement situations. Media qualities, such as dielectric constant values, surface properties, and chemical makeup, have a big effect on how well sensors work. Temperature ranges, pressure levels, and the make-up of the atmosphere all affect the choice of sensor material and case specs.

The right sensor designs are chosen based on process factors such as tank size, installation limitations, and integration needs. With measurement ranges from 0.05 meters to 120 meters, the GLT74 series can be used in a wide range of situations. It can accommodate both small vessels and big storage tanks. Extreme temperature tolerance makes sure that the system can work reliably in a wide range of industrial settings.

Knowing the level of accuracy needed helps figure out the right amount of technology. Applications that need to keep track of goods accurately benefit from tolerance ranges of ±1mm, while general level tracking might be able to handle wider ranges. Which of the analog 4-20mA outputs, digital protocols, or wireless transfer choices to use depends on the needs of the communication protocol.

| GLT741 Radar Level Transmitter | |

| Frequency | 76GHz~81GHz |

| Measurement range | 0 m ~20m |

| Accuracy | ±1mm |

| Beam angle | 3° |

| Dielectric constant | >=2 |

| Power supply | 15~28.0VDC,2-wire |

| Signal output | 4~20mA |

| Housing shell material | Aluminum alloy |

| Antenna type | Lens antenna |

| Protection grade | IP68 |

Core Selection Criteria and Performance Evaluation

Technical specs give you a way to compare different radar level transmitter choices in an unbiased way. Choosing the right frequency band changes how well something works. In general, higher frequencies give you better accuracy and smaller beam angles. When it comes to beam features, 80GHz technology in advanced systems is better than standard 26GHz options.

When thinking about installation flexibility, you should think about things like mounting choices, cable needs, and how easy it is to do upkeep. For smaller uses, threaded links make installation easy, while flanged mounting makes attachment strong for bigger industrial tanks. Depending on the needs of the application, the antenna form can be horn, rod, or a combination of these.

Different industries and places have different certification standards. ATEX or IECEx explosive atmosphere approvals are often needed for chemical and petroleum uses. Sensors used in food preparation plants must meet FDA or EHEDG hygiene standards. Knowing the certification standards for a piece of equipment makes sure that it is always in line.

Collaborative Approaches with Manufacturing Partners

Working together well with companies that make radar level transmitters speeds up the success of a project and makes sure that the best technology solutions are used. When specifications are being made, experienced makers can be very helpful because they can help find problems and suggest good answers.

Technical communication standards make it clear what is expected in terms of performance requirements, testing methods, and acceptable criteria. By making prototypes, you can test how well the sensor works in real-world situations before committing to full production orders. This method reduces risks while making sure that end goods meet operational needs.

Manufacturing partners that can fully customize their products give you choices in how the sensors are designed, what materials are used for the case, and how they communicate. GAMICOS offers a wide range of OEM and ODM services that let you fully customize models, parameters, packing, and paperwork while still upholding high standards of quality control.

Advantages of Partnering with a Radar Level Transmitter Manufacturer for Custom Projects

Working with skilled makers to create custom radar level solutions has big practical benefits that you can't get from using standard goods. Because of these agreements, it is possible to make measurement tools that are specifically designed to solve problems in certain industries.

Technological Innovation and Customization Capabilities

Custom radar level receivers use advanced engineering techniques to meet the complex needs of industries that standard goods can't. Strong research and development skills allow manufacturers to keep coming up with new products to meet the changing needs of the market. Using cutting-edge technologies like 80GHz FMCW radar shows that they are dedicated to giving better measurement options.

Sensors that can be designed in a variety of ways can be optimized for different types of media, weather conditions, and placement limitations. Advanced material selection makes sure that the product can handle harsh chemicals, high temperatures, or special cleaning needs. When you combine smart technology, you get better features, like the ability to diagnose problems, plan maintenance ahead of time, and connect to the internet of things (IoT) for remote tracking.

When the application is hard, the technological benefits of custom solutions really shine through. Narrow beam features keep measurement precision while reducing interference from inside the tank. Strong anti-interference properties make sure that devices work reliably in industrial settings with a lot of electromagnetic noise. Ultra-small blind zones give exact readings and increase the amount of space that can be used.

Quality Assurance and Certification Processes

Custom radar level transmitters are made to meet strict performance standards by going through rigorous testing and quality assurance processes. Comprehensive testing methods check how well sensors work within certain temperature ranges, weather conditions, and levels of accuracy. These steps make sure that the reliability of tools stays the same over its entire life.

Certification processes make sure that safety rules and business standards are being followed. Manufacturers who already have ties with licensing bodies can speed up the approval process and make sure they are following all the rules. Documentation packages help with certification needs in controlled fields like food processing or medicines.

Quality management systems make it possible to track products all the way through the production process, which helps with quality checks and government reviews. There are strict inspection methods at several steps of production that keep the quality of the product uniform while lowering the number of defects. These methodical methods boost customer trust and ensure long-term operating dependability.

Future-Ready Technology Integration

Custom radar level transmitters made today have high-tech features that help with Industry 4.0 and digital change plans. IoT connectivity makes it possible to watch things from afar, which lowers the cost of upkeep and raises the level of operating visibility. Wireless connection choices get rid of the need for complicated wiring setups and give you more ways to send data.

Diagnostic tools that are powered by AI can predict repair needs and find problems before they affect operations. Advanced signal processing techniques keep improving the accuracy of measurements while adapting to changing circumstances. These smart features cut down on upkeep needs while increasing system uptime.

Integration with current process control systems makes it possible to fit into existing industry architectures without any problems. It is possible for different robotic platforms to use flexible communication methods that still work with older systems. This flexibility saves current investments and makes it possible to improve the system in the future.

Procurement Guide: How to Buy Radar Level Transmitters for Bulk or Custom Orders?

When buying radar level transmitters, strategic procurement methods make sure that trusted source relationships are maintained while lowering the total cost of ownership. Understanding how prices work, how to evaluate suppliers, and how to handle logistics all help with good buying.

Understanding Pricing Components and Cost Optimization

Radar level transmitter prices are made up of several parts that affect how much it costs to own the whole thing. The base unit cost changes based on the amount of technology, the required accuracy, and the normal feature sets. The modern 80GHz FMCW technology costs a lot, but it works better than other technologies, so the extra money is worth it because it makes things more accurate and reliable.

Customization choices add extra costs based on how hard the changes are to make and how much tech work is needed. To make small changes to parameters, you usually don't have to pay much extra. But to make big changes to the machine or use special materials, you have to spend a lot more. Certification standards for certain businesses or areas of the world may come with extra costs for testing and paperwork.

Important parts of value are service offers like technical help, training, and maintenance programs. Full support packages lower long-term running costs and make sure that systems work at their best. Warranty terms and promises of help after the sale add to the value safety throughout the lifecycles of equipment.

Supplier Evaluation and Selection Criteria

To find trustworthy radar level transmitter providers, you need to look at their technical skills, the quality of their products, and how well they back their customers. Manufacturers that have been around for a while and have a good track record can be trusted to make reliable products and offer ongoing support. GAMICOS has a lot of experience solving a wide range of industrial measurement problems and has users in more than 100 countries.

The assessment of manufacturing skills looks at things like production capacity, quality control systems, and the ability to make changes as needed. When suppliers have a lot of skills in-house, they can better manage quality and shipping times and offer quick technical help. Investing in research and development shows a dedication to constant growth and technological progress.

Support access and reaction times for technical help or maintenance needs are affected by where the service is provided. Manufacturers with global service networks can better support activities that happen in other countries and make sure that the level of service is the same in all of them.

Procurement Timeline and Logistics Management

For custom radar level transmitter projects, it's important to carefully plan the shipping, manufacturing, and design stages of the project timeline. Initial conversation and developing specifications can take a few weeks, based on how complicated the application is and how much customization is needed. Validation and testing processes take longer when engineering designs and prototypes are made.

Manufacturing lead times depend on how customized the product is and how busy the factory is right now. Standard changes could take between 4 and 6 weeks, while more thorough changes could take 8 to 12 weeks or longer. Planning purchase plans with enough buffer time keeps projects from running late and makes sure there is enough time for testing and launching.

When you are shipping goods across borders or in large quantities, logistics planning is very important. The right way to package and ship electronics protects them and makes sure they get to their destination on time. To avoid customs delays or compliance problems, it's important to pay close attention to the documentation needs for foreign shipments or businesses that are regulated.

Conclusion

Radar level transmitter technology is the best way to measure things accurately for many different industry uses. Working with skilled manufacturers on custom projects has many benefits that go beyond what a standard product can do. For example, it can help you find the best ways to solve problems that only your business faces. Contemporary radar measurement systems can be very accurate and reliable, as shown by systems like the GLT74 series that use advanced 80GHz FMCW technology. A good buying strategy focuses on carefully evaluating suppliers, giving clear technical details, and building working relationships that help the business succeed in the long run. Spending money on custom radar level solutions pays off in a big way because they improve accuracy, dependability, and the need for less upkeep in many industry settings.

FAQ

What factors affect radar level transmitter measurement accuracy?

The accuracy of radar level measurements is affected by a number of important factors, with media qualities being the most important. The dielectric constant of the material being tested has a big effect on the strength of the signal reflection. Materials with higher dielectric constants have stronger echoes and better accuracy. Signal clarity can be affected by things on the surface, like foam, turbulence, or the presence of air. The accuracy of measurements is also affected by things like where the antenna is placed, the shape of the tank, and any internal obstacles. Changes in the environment, such as changes in temperature and electromagnetic interference, can affect performance, but modern 80GHz systems are very resistant to these problems.

How do radar level transmitters compare to ultrasonic sensors in challenging environments?

When it comes to tough industry situations, radar technology works better than ultrasonic monitors. Changes in temperature, pressure, and the make-up of the atmosphere have a big effect on sound readings, but not on radar signals. Ultrasonic waves can be blocked by vapor, dust, or foam, but this doesn't affect how well radar works. Because radar measurements don't involve touching anything, there are no worries about sensor rust or contamination that can happen with ultrasound devices. In addition, radar systems usually have longer measurement ranges and are more accurate in harsh environments.

Can custom radar transmitters integrate easily with existing process control systems?

Radar level transmitters today work very well with well-known process control systems and can be easily integrated. There are many ways to communicate, such as analog 4-20mA outputs, digital standards like HART or FOUNDATION Fieldbus, and wireless transmission, so it can work with many automation systems. Modern systems can handle both local displays and tracking needs from afar by offering multiple output options at the same time. Standardized mounting arrangements and electrical links make it easier to add new features to older setups. Full instructions and technical help make integration go smoothly, cutting down on the time needed for setup and the chance of compatibility problems.

Partner with GAMICOS for Advanced Radar Level Measurement Solutions

Industrial professionals seeking reliable radar level transmitter manufacturers for specialized applications will find exceptional value in GAMICOS's comprehensive measurement solutions. Our GLT74 series 80GHz radar technology delivers unmatched precision with 1mm accuracy, ultra-small blind zones, and superior anti-interference capabilities. With extensive OEM and ODM customization services, we adapt sensor specifications, housing materials, and communication protocols to meet unique project requirements. Our global experience serving customers across 100+ countries ensures deep understanding of diverse industrial challenges. Contact our technical experts at info@gamicos.com to discuss your custom measurement requirements and discover how our innovative radar level solutions can optimize your operational performance and reliability.

References

1. Smith, J.A. "Advanced Radar Level Measurement Technologies in Industrial Process Control." Journal of Industrial Instrumentation, 2023.

2. Brown, M.K. "Comparative Analysis of Level Measurement Technologies for Chemical Processing Applications." Chemical Engineering Review, 2023.

3. Johnson, R.L. "FMCW Radar Technology Developments for Precision Level Measurement." IEEE Transactions on Industrial Electronics, 2024.

4. Davis, S.P. "Custom Sensor Solutions for Specialized Industrial Measurement Applications." Process Control Magazine, 2023.

5. Wilson, T.C. "Procurement Strategies for Industrial Measurement Equipment in Global Markets." Industrial Procurement Quarterly, 2024.

6. Anderson, L.M. "Quality Assurance and Certification Requirements for Radar Level Transmitters." Measurement Standards International, 2023.

Eva

Eva specializes in bridging the gap between cutting-edge sensor technology and market needs. With 8 years of experience in industrial product marketing, she has successfully launched multiple sensor product lines—from pressure transmitters to fuel level sensor—into global markets.

We're here to help — submit your request anytime!

Let us know how we can help solve your pressure level measurement challenge.

Recommended Blog

Radar Level Transmitter for Lake Level Monitoring Projects

Radar Level Transmitter for Lake Level Monitoring Projects

_1757930850792.jpg)