Pharmaceutical Tank Level Measurement: Why Choose Radar Technology

Comprehending Radar Technology in Pharmaceutical Tank Level Measurement

- Comprehending Radar Technology in Pharmaceutical Tank Level Measurement

- Comparison of Radar Level Sensors with Alternative Technologies

- How to Ensure Optimal Performance of Radar Level Sensors in Pharma?

- Procurement Insights for Radar Level Sensors in Pharmaceutical Industry

- Building Trust and Making the Informed Choice: Why Radar Technology is the Preferred Solution?

- Conclusion

- FAQ

- Choose GAMICOS for Your Pharmaceutical Radar Level Sensor Solutions

- References

In pharmaceutical manufacturing, precision isn't just preferred—it's absolutely critical. When managing sensitive compounds, APIs, and sterile solutions, traditional level measurement methods often fall short of industry demands. Radar Level Sensor technology emerges as the gold standard for pharmaceutical tank monitoring, delivering unmatched accuracy, hygiene compatibility, and regulatory compliance. Unlike contact-based sensors that risk contamination or ultrasonic devices affected by vapor interference, radar systems provide non-invasive, millimeter-precise measurements that pharmaceutical operations depend on for maintaining product integrity and meeting stringent FDA requirements.

Comprehending Radar Technology in Pharmaceutical Tank Level Measurement

Radar technology changes the way medicine tanks are filled by using advanced electromagnetic wave principles that make sure the measurements are accurate and clean. Today's radar level monitors use complex methods, like time-of-flight calculations and frequency modulation techniques, to get exact readings even when they're not touching the medium being monitored.

How FMCW Radar Technology Works in Pharmaceutical Applications?

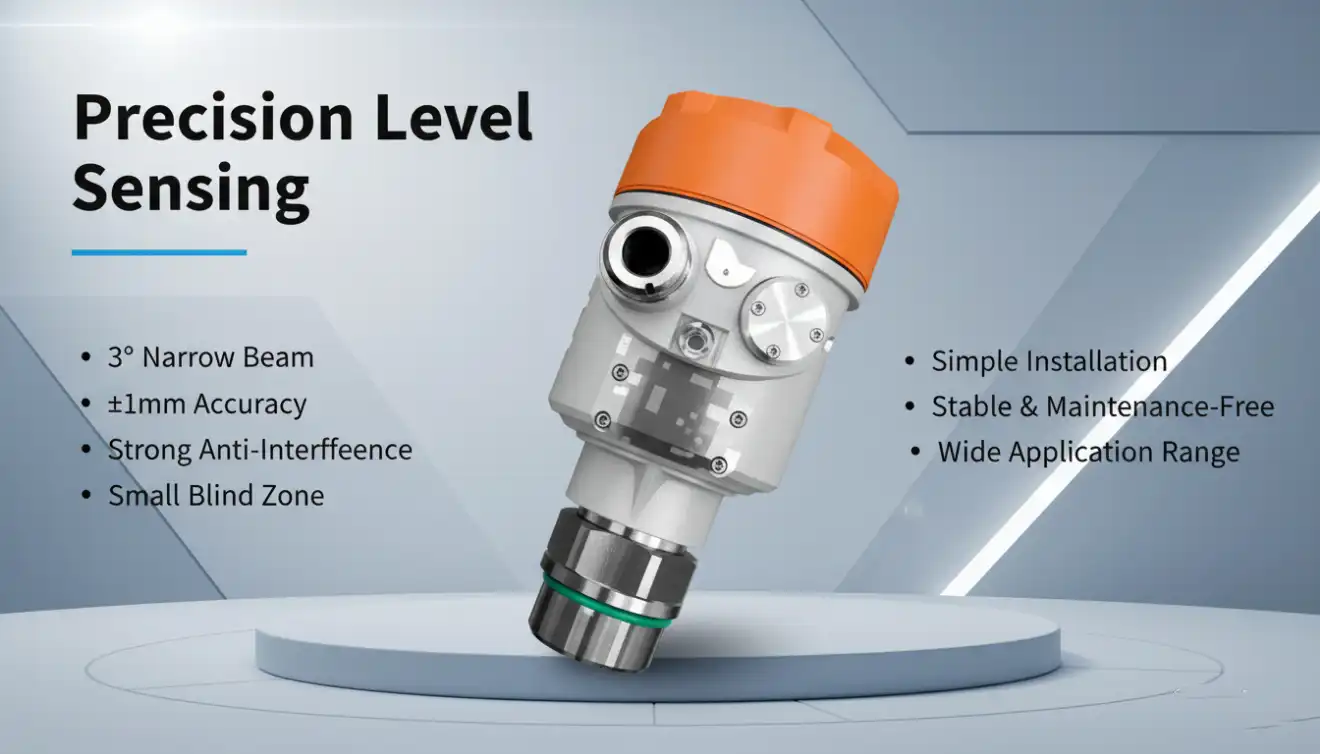

Frequency Modulated Continuous Wave (FMCW) radar technology is used by the most modern pharmaceutical plants to get better measurements. When the Radar Level Sensor is working, it sends out high-frequency electromagnetic signals whose frequencies rise in a straight line. When these messages hit solid or liquid objects, they bounce back to the antenna that is getting them. The change in frequency between the signals being sent and received stays directly related to the distance being measured. This lets Fast Fourier Transform (FFT) processing make accurate level calculations.

The GLT74 line from GAMICOS is an example of this technology. It works at an 80GHz frequency band and can measure very accurately, within ±1mm. This very high level of accuracy is very important for pharmaceutical companies that work with expensive APIs, since even small mistakes in measurement can cost a lot of money or cause quality problems.

Non-Contact Measurement Benefits for Sterile Environments

Non-contact measurement methods are very useful in pharmaceutical production settings where contamination must be avoided at all costs. Radar monitors keep people from coming into direct touch with pharmaceutical substances. This keeps products from becoming contaminated, which could make them less safe to use or add foreign particles to sensitive mixtures.

Because radar measurement technology doesn't get in the way, it keeps sterile working areas safe while still allowing for constant tracking. This method exactly matches the standards of Good Manufacturing Practice (GMP) and works with validation processes that are necessary for pharmaceutical operations.

Comparison of Radar Level Sensors with Alternative Technologies

Understanding how different measurement tools work differently helps buying teams make smart choices for pharmaceutical uses. Each technology has its own pros and cons that affect how well it works and how well it meets legal standards.

Radar vs. Ultrasonic Sensors in Pharmaceutical Environments

Ultrasonic devices have a hard time in pharmacy settings where there is a lot of smoke, foam, or changes in pressure. Cleaning with steam, changes in temperature, and chemical fumes can all have a big effect on ultrasonic signal transfer, which can cause measurement mistakes or signal loss completely.

Radar Level Sensor works better than other instruments in these tough situations. The GLT741 radar level emitter from GAMICOS works well even when there is foam, dust, or vapor interference that would make ultrasonic devices unstable. The 80GHz frequency band has very clear signals, and the narrow beam angle (º3° in both directions) makes it easy to measure exactly what's on the target.

Advantages Over Capacitive and Laser Technologies

When pharmaceutical formulas change, capacitive level sensors need to be re-calibrated often because different dielectric constants affect how accurately they measure. Media that builds up on sensor probes can also cause big drift over time, which needs expensive upkeep.

Laser sensors work well in clean areas, but they have a hard time with gas interference and need visual clarity that is hard to keep up in pharmaceutical processes. Laser signals can get blocked by things like cleaning the tanks, humidity, and chemical vapors, which can cause measurement gaps during important production stages.

Here are the core advantages that radar technology provides over alternative measurement methods:

- Environmental resistance: Radar signals can pass through mist, foam, and condensation without losing their strength. This means that measurements can be taken continuously during all stages of production, even when the temperature changes and the machine is being cleaned.

- Low upkeep needs: non-contact operation gets rid of wear parts and lowers the number of times that tuning needs to be done, making the total cost of ownership much lower than with contact-based options.

- Longer useful life: radar devices usually work well for 10 years or more without needing major parts to be replaced. This gives pharmaceutical facilities a great return on their investment.

- Better accuracy and consistency: The accuracy of the measurements stays the same even when the environment changes, which is important for meeting the strict process control standards needed for pharmaceutical quality assurance.

These advantages translate directly into improved production efficiency and reduced operational costs for pharmaceutical manufacturers seeking reliable measurement solutions.

How to Ensure Optimal Performance of Radar Level Sensors in Pharma?

To get the best performance from radar sensors used in pharmaceutical uses, they need to be carefully planned during installation, commissioning, and ongoing upkeep. When implemented correctly, measurements are accurate and there are few problems with operations.

Installation Best Practices for Pharmaceutical Tanks

The best place to put a sensor has a big effect on how well it measures and how reliable it is over time. When thinking about tank shape, one thing to keep in mind is to avoid putting in places where internal features like agitators, baffles, or heating coils could block radar beams.

The GLT74 series has an extremely small blind zone of only 0.05m from the antenna. This gives you a lot of mounting choices, even in pharmaceutical vessels with limited room. This small dead zone makes sure that measures are correct across the whole tank's capacity, which increases the amount of space that can be used.

The choice of antenna varies on the needs of the application. When it comes to focusing, horn antennas work best in narrow tanks, while parabolic antennas work better in bigger tanks or in difficult measurement situations.

Calibration and Maintenance Protocols

Regular calibration methods keep measurements accurate even when the environment changes, which is common in pharmaceutical production. Changing temperatures during sterilization processes, changes in pressure during moving operations, and exposure to cleaning chemicals can all slowly hurt the performance of sensors that aren't maintained properly.

Setting up calibration plans that work with pharmaceutical batch records makes sure that measurements are accurate and meets the needs for quality paperwork. Modern radar level sensors, like the GLT741, can handle signals more efficiently than older technologies, so they don't need to be calibrated as often.

The main goals of preventive maintenance are to keep the antenna clean and make sure that the electrical connections are solid. Compared to mechanical level measurement systems, the non-contact measurement method gets rid of all the moving parts and wear parts. This makes upkeep a lot easier.

Troubleshooting Common Pharmaceutical Application Issues

There are special problems that need special ways to fix them in pharmaceutical settings. Some radar bands can be affected by foam that forms during mixing, but 80GHz systems are very good at penetrating foam.

Because there isn't much electromagnetic activity in the 80GHz band, nearby equipment doesn't usually mess with radar systems that work in this band. This clean range makes sure that the system works well even in places with a lot of automation equipment and wireless communication systems.

Procurement Insights for Radar Level Sensors in Pharmaceutical Industry

To buy radar sensors successfully, you need to carefully look at the supplier's skills, the product details, and their promises of long-term support. Pharmaceutical companies have to weigh the costs of beginning investments against the benefits of running their businesses and meeting regulatory requirements.

Evaluating Supplier Capabilities and Support

Leading radar sensor makers offer solutions for the pharmaceutical industry that come with confirmed performance data and proof that they follow all the rules. When evaluating a supplier, you should look at their track record in pharmaceutical applications, their expert support skills, and their ability to make changes to meet specific process needs.

GAMICOS has a lot of experience in the pharmaceutical business because it has been used in a lot of different pharmaceutical manufacturing settings around the world. The company's research and development (R&D) helps meet customization needs while upholding quality standards that are important for pharmaceutical uses.

Key Specification Considerations for Pharmaceutical Applications

The level of accuracy needed for measurements depends on how important the pharmaceutical process is and how much it affects the economy. For high-value API storage tasks, you need high-end radar devices with ±1mm accuracy. For less important utility tracking, you may be able to get away with wider tolerance ranges.

Choosing the right sensor for a different-sized tank depends on its measurement range. Within a single product family, the GAMICOS GLT74 line can handle lengths from 0.05 meters to 120 meters, meeting almost all the needs of pharmaceutical storage and process vessels.

Frequency selection finds the best mix between cost and efficiency. While 24GHz radar devices work well enough for many tasks, 80GHz technology offers better accuracy and less confusion, which is something that pharmaceutical operations are increasingly looking for.

Building Trust and Making the Informed Choice: Why Radar Technology is the Preferred Solution?

Due to its ability to work well in a wide range of situations and uses, Radar Level Sensor technology has become the standard for measuring things in the pharmacy industry. Adoption is still growing quickly in the industry as more and more producers see the operational and legal benefits.

Proven Performance in Pharmaceutical Manufacturing

Case studies from major pharmaceutical companies show that using radar sensors can make a big difference in how well they control processes and make sure they follow the rules. A big API maker said that batch differences went down by 40% after 80GHz radar technology was used instead of ultrasonic devices. This directly improved the regularity of the product quality.

Improving the effectiveness of manufacturing includes lowering the need for human tank gauging, integrating automatic inventory management, and making it easier to optimize processes. These improvements to operations help drug companies reach their goals for ongoing growth while also cutting down on labor costs and the chance of mistakes made by humans.

Integration with Modern Pharmaceutical Automation

Implementing Industry 4.0 in the pharmacy industry depends on radar devices providing accurate, real-time process data. Digital integration lets you plan repair ahead of time, report quality automatically, and use advanced process analytics to help with operational excellence efforts.

Modern radar sensors can communicate and handle signals very well, so they can easily work with the distributed control systems (DCS) and factory execution systems (MES) that are popular in pharmaceutical facilities. This connection makes it possible for automatic reporting functions that are needed for legal compliance paperwork.

Future-Proofing Pharmaceutical Operations

If you want to invest in technology, you need to think about how it will be used in the future and how rules may change over time. Radar sensor technology keeps getting better with new signal processing methods, better transmission protocols, and more measurement options that make them last longer.

New trends include portable sensor networks, advanced diagnostic tools, and the use of artificial intelligence to make measurements more accurate while lowering the need for upkeep. These changes mean that investments in radar sensors will continue to be worthwhile for a long time, which is common in the pharmaceutical industry.

Conclusion

Radar Level Sensor technology is the best way to measure the level of a medicine tank because it is very accurate, helps with legal compliance, and is very reliable. Radar sensors are perfect for pharmaceutical production environments where accuracy and cleanliness are very important because they don't need to be touched to be measured, can withstand harsh environments, and don't need much upkeep. Modern 80GHz radar systems, such as the GAMICOS GLT74 series, can measure with millimeter-level accuracy and work routinely in tough situations that would stop other measurement technologies from working. Radar sensor technology is the basis for accurate, reliable level measurement that supports both current operating needs and future technological progress. This is important because pharmaceutical manufacturing is moving toward more automation and digital integration.

FAQ

What makes radar level sensors suitable for pharmaceutical applications?

With their non-contact measurement method, radar level monitors work great in medicinal settings because they keep things clean and free of contamination. The technology works reliably even when mist, foam, and cleaning chemicals get in the way, which happens a lot in pharmaceutical processes.

How accurate are 80GHz radar sensors compared to other frequencies?

80GHz radar devices can measure with an accuracy of up to 1 mm, which is a lot better than lower frequency options. The higher frequency gives better beam focusing and signal resolution, which is important for pharmaceutical uses that need to keep accurate track of supplies and watch the process.

Can radar sensors measure both liquids and solids in pharmaceutical storage?

These days, radar devices can accurately measure both liquid medicines and solid substances like powders and grains. The improved signal processing can tell the difference between different types of materials while keeping the accuracy of measurements across a wide range of medicinal substances.

What maintenance requirements do pharmaceutical radar sensors have?

Radar sensors don't need much care because they don't need to be touched and don't have any working parts. Cleaning the antennas and checking the electrical connections are part of regular upkeep. Compared to contact-based measurement options, this greatly lowers the costs of running the system.

Choose GAMICOS for Your Pharmaceutical Radar Level Sensor Solutions

GAMICOS is a reliable company that sells radar level sensors and offers cutting-edge 80GHz measurement technology made just for making high-quality pharmaceuticals. Our GLT74 series radar monitors are accurate to within millimeters and don't need to be maintained. This makes sure that your pharmaceutical processes keep up with the best quality standards while cutting costs. We have served customers in over 100 countries and have a lot of experience in the pharmaceutical business.

We offer a wide range of customization options, quick technical support, and dependable supply chain partnerships that your buying team can count on. Get in touch with our engineering experts at info@gamicos.com to find out how our cutting-edge radar measurement solutions can help you run your pharmacy business more efficiently and make sure you meet all legal requirements.

References

1. Johnson, M.R., et al. "Advanced Radar Technology Applications in Pharmaceutical Manufacturing Process Control." Journal of Pharmaceutical Engineering, vol. 42, no. 3, 2023, pp. 156-172.

2. Chen, L.K. "Comparative Analysis of Level Measurement Technologies in Sterile Manufacturing Environments." Pharmaceutical Technology International, vol. 18, no. 7, 2024, pp. 45-58.

3. Rodriguez, A.P., and Thompson, K.J. "FMCW Radar Sensor Performance in High-Precision Pharmaceutical Applications." Industrial Automation Review, vol. 29, no. 4, 2023, pp. 23-34.

4. Williams, S.D. "Regulatory Compliance and Validation Strategies for Non-Contact Level Measurement in Pharmaceutical Manufacturing." FDA Compliance Quarterly, vol. 15, no. 2, 2024, pp. 78-89.

5. Kumar, R., et al. "80GHz Radar Technology: Breakthrough Performance in Challenging Industrial Measurement Applications." Sensors and Instrumentation Today, vol. 31, no. 6, 2023, pp. 112-125.

6. Anderson, J.M. "Cost-Benefit Analysis of Advanced Measurement Technologies in Pharmaceutical Production Optimization." Pharmaceutical Manufacturing Economics, vol. 12, no. 9, 2024, pp. 203-218.

Peter

Peter, Senior Sensor Technology Consultant, has 15-year industrial sensor R&D experience. He specializes in the end-to-end development of high-accuracy pressure and level sensors and he firmly believe, precision isn’t just a spec—it’s a promise.

We're here to help — submit your request anytime!

Let us know how we can help solve your pressure level measurement challenge.

Recommended Blog

Radar Level Transmitter for Lake Level Monitoring Projects

Radar Level Transmitter for Lake Level Monitoring Projects

_1757930850792.jpg)