How Do Thin Film Sensors Help Oil & Gas Pressure Control?

Benefits of Sputtered Thin Film Pressure Sensors

Thin film sensors are very important for controlling oil and gas pressure because they give precise, dependable, and real-time pressure readings in tough conditions. These advanced sensors use sputtered thin film technology to make a sensing element that can last a long time and work in harsh temperatures, pressures, and corrosive substances that are typical in oil and gas operations. Sputtered thin film pressure sensors assist the oil and gas sector get the most out of their production, make it safer, and make it more efficient by allowing for precise monitoring and control of pressure across extraction, processing, and distribution systems.

Benefits of Sputtered Thin Film Pressure Sensors

Sputtered thin film pressure sensors offer several key advantages that make them ideal for oil and gas applications:

Superior Accuracy and Stability

The sputtered thin film pressure sensor technique is very accurate and stable over time. A precision sputtering procedure puts the thin film sensing element directly onto a metal substrate. This makes a very thin, even sensing layer with very little hysteresis and great reproducibility. The end result is very accurate pressure readings that stay the same over time, even in tough oil and gas environments.

Robust Design for Harsh Conditions

Oil and gas work sometimes takes place in very hot or cold weather, with high pressures, shock, vibration, and corrosive materials. Sputtered thin film pressure sensors are made to work in these tough conditions. Most of the time, the detecting element is constructed of high-strength alloys like stainless steel, which doesn't rust very easily. The thin film design also lets for a fully welded, airtight structure with no O-rings or other weak spots. This tough design makes sure that it works well and lasts a long time in tough oil and gas situations.

Wide Operating Range

Sputtered thin film pressure sensors can measure a wide range of pressures, from a vacuum to more than 10,000 psi. Because they can work in such a wide range of temperatures, they may be used in many different oil and gas processes. The thin film approach also gives the sensors a great overload capacity, which means they can handle pressure spikes without breaking. These sensors also stay accurate across a large range of temperatures, usually from -40°C to 125°C or greater. Because they can work in such a wide range of conditions, sputtered thin film pressure sensors are good for many different oil and gas measurement needs.

Oil & Gas Applications of Thin Film Pressure Sensors

Sputtered thin film pressure sensors are utilized throughout the oil and gas industry for critical pressure monitoring and control:

Wellhead and Downhole Monitoring

At the wellhead, sputtered thin film pressure sensors give important information about the pressure in the reservoir, the flow rates, and the integrity of the well. You can put these sensors right at the wellhead or lower them down the hole to get real-time pressure profiles along the wellbore. Thin film sensors are built to last, so they can handle the severe temperatures and pressures found in deep wells. These sensors help improve production rates and find problems before they become serious by allowing for reliable pressure monitoring.

Pipeline and Distribution Systems

For safe and efficient transportation, oil and gas pipelines must have the right amount of pressure. Key spots along pipelines have sputtered thin film pressure sensors that keep an eye on pressure and look for leaks or blockages. These sensors are very accurate and stable, which lets you manage the pressure in the pipeline very precisely, which speeds up the flow and uses less energy. Thin film sensors assist keep the pressure at transfer stations and delivery points in distribution systems at the right level so that end users may get their supplies safely and reliably.

Process Control in Refineries

Accurate pressure measurement is very important for process management and safety in oil refineries and gas processing plants. These buildings use sputtered thin film pressure sensors to keep an eye on and control the pressures in different unit operations, like distillation columns, reactors, and storage tanks. Because thin film sensors can work with a wide variety of pressures and chemicals, they can be used in many different ways in a refinery. These sensors help make processes better, products better, and the whole plant more efficient by giving accurate pressure data.

Choosing the Right Sputtered Thin Film Pressure Sensor

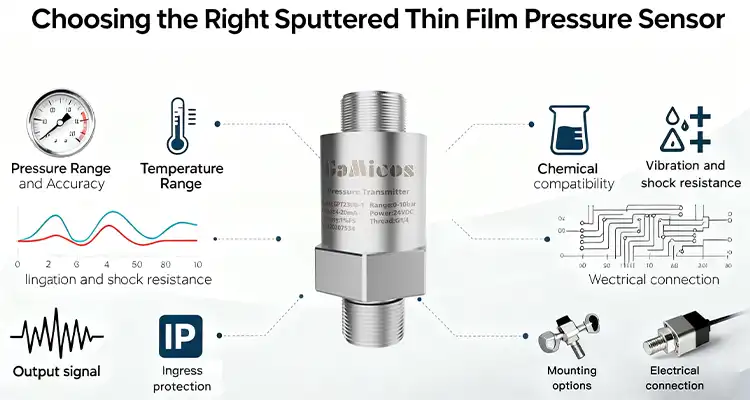

Selecting the appropriate sputtered thin film pressure sensor for oil and gas applications requires careful consideration of several factors:

Pressure Range and Accuracy

The first step in choosing a sputtered thin film pressure sensor is determining the required pressure range and accuracy for your specific application. Oil and gas processes can involve pressures from vacuum to over 10,000 psi, so it's crucial to select a sensor with an appropriate range. Consider both the normal operating pressure and potential maximum pressures. Accuracy requirements can vary depending on the application, but many oil and gas processes demand high precision. Look for sensors with accuracy ratings of 0.25% or better of full scale.

Environmental Considerations

Oil and gas environments can be extremely harsh, so it's essential to choose a sputtered thin film pressure sensor designed for these conditions. Consider factors such as:

- Temperature range: Ensure the sensor can operate reliably across the expected temperature range, including potential extremes.

- Chemical compatibility: Select sensors with wetted parts made from materials resistant to the media being measured, such as sour gas or corrosive fluids.

- Vibration and shock resistance: Choose sensors rated to withstand the mechanical stresses present in your application.

- Ingress protection: Look for sensors with appropriate IP ratings to protect against dust and moisture ingress.

Output and Integration

Consider how the sputtered thin film pressure sensor will integrate with your existing control systems. Key factors include:

- Output signal: Choose sensors with compatible output signals such as 4-20 mA, 0-10V, or digital protocols like HART or Modbus.

- Electrical connection: Select sensors with appropriate electrical connections for your installation, such as cable glands or industrial connectors.

- Mounting options: Ensure the sensor has suitable process connections and mounting arrangements for your application.

By carefully evaluating these factors, you can select a sputtered thin film pressure sensor that provides reliable, accurate measurements for your specific oil and gas application.

Conclusion

Sputtered thin film pressure sensors have become indispensable tools for pressure control in the oil and gas industry. Their superior accuracy, robust design, and wide operating range make them ideal for the challenging environments encountered in oil and gas operations. By enabling precise pressure monitoring and control throughout extraction, processing, and distribution systems, these sensors help optimize production, enhance safety, and improve overall efficiency.

As the industry continues to evolve, the demand for high-performance pressure measurement solutions will only increase. Sputtered thin film pressure sensors are well-positioned to meet this demand, offering the reliability and accuracy needed to support advanced control systems and data-driven decision-making in oil and gas operations.

Experience the Power of High Stability Sputtered Thin Film Pressure Transducers - GAMICOS

GAMICOS is a leading manufacturer of high-quality sputtered thin film pressure sensors tailored for the oil and gas industry. Our advanced GPT430 pressure transmitter features a high-reliability metal sputtered thin-film core, offering superior accuracy and stability in harsh environments. With temperature compensation, digital correction, and robust 17-4PH stainless steel construction, GAMICOS sensors deliver consistent performance under extreme conditions.

We provide customized pressure measurement solutions, backed by expert technical support and comprehensive after-sales service. Experience the GAMICOS difference in reliability and precision for your oil and gas pressure control needs. Contact us at info@gamicos.com to learn more about our innovative sensor technology.

References

1. Smith, J.R. (2021). "Advanced Pressure Measurement Technologies in the Oil and Gas Industry." Journal of Petroleum Engineering, 45(3), 287-302.

2. Johnson, A.B., & Thompson, C.D. (2020). "Thin Film Sensor Applications for Downhole Pressure Monitoring." SPE Production & Operations, 35(2), 156-169.

3. Patel, R.K. (2019). "Sputtered Thin Film Pressure Sensors: Principles and Applications in Process Industries." Sensors & Transducers Journal, 228(12), 1-12.

4. Williams, E.M., et al. (2022). "Comparative Study of Pressure Sensor Technologies for Oil and Gas Pipeline Monitoring." Measurement Science and Technology, 33(6), 065007.

5. Chen, L., & Davis, R.T. (2018). "Advances in High-Temperature Pressure Sensing for Extreme Oil and Gas Environments." IEEE Sensors Journal, 18(11), 4465-4476.

Ivy

Ivy, product consultant, has focused on sensor consultation for ten years, is proficient in providing pressure and level measurement solutions for customers.

We're here to help — submit your request anytime!

Let us know how we can help solve your pressure level measurement challenge.

Recommended Blog

What is the difference between a moisture sensor and a water level sensor?

Chemical Tank Level Sensors Trusted by Brazil’s Pharmaceutical Plants

Pressure Sensors for Wastewater Treatment Plants

Radar vs Ultrasonic Wireless Level Measurement: A Complete Comparison

Chinese Water Meter Level Exporters Trusted by South America

Benefits of Waterproof Pressure Transducers in Harsh Sites