When choosing level measurement technology for business use, ultrasonic level meters and sensitive level monitors are two popular choices. The main difference is how they measure distance: capacitive devices look at changes in electrical capacitance, while ultrasonic level meters use sound waves to find distance without touching anything. Ultrasonic systems work best in tough settings because they don't need to be touched and can reach distances of up to 40 meters. Capacitive sensors, on the other hand, need to be in direct contact with the thing being measured to give accurate results.

Understanding Ultrasonic Level Measurement Technology

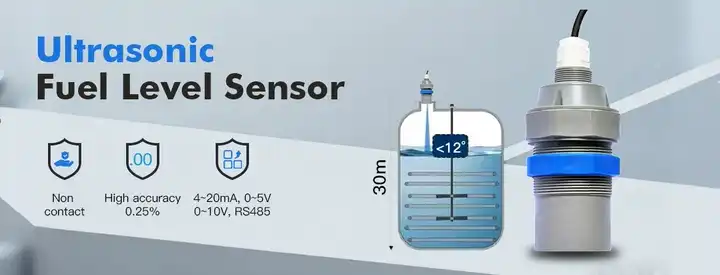

Time-of-flight concepts are used by ultrasonic level meters to send high-frequency sound waves toward a surface. The sound pulses move through the air and bounce back to the detector. The system can figure out how far something is by measuring how long it takes to travel.

The technology has a number of benefits:

• Non-contact testing gets rid of the chance of contamination

• Can be used with acidic and rough materials

• Wide measurement ranges, from 0.3 to 40 meters

• Processing in real time

• Doesn't need much care

Modern ultrasound devices use more complex signal processing techniques to get better results. Echo recognition technology blocks out background noise, and smart sensor features allow IoT integration for monitoring from afar.

In chemical storage tanks or wastewater treatment plants where accurate measurements are needed to keep operations safe, ultrasonic level meters are the best choice.

Capacitive Level Sensor Operating Principles

Capacitive level sensors measure changes in the electrical capacitance between the probe wires and the walls of the tank to find changes in level. The dielectric constant changes when the levels of the media go up or down, which causes changes in the electrical field that can be measured.

Some important features are:

• High-precision direct contact measurement

• Use of both conductive and non-conductive liquids

• Small probe designs for setups with limited room

• High sensitivity for small volume changes

• Compatibility with embedded systems

These monitors work great in situations where precise control is needed, like when making medicines or cooking food where accuracy is very important.

Most of the time, sensitive level monitors are better for applications that need accurate level control in smaller tanks with clean media.

Installation and Maintenance Considerations

The installation needs for these measuring systems are very different. Ultrasonic level meters need to be mounted at the right height and with enough beam space so that they don't get messed up by things inside the tank or by agitators.

Three main changes in installation:

1. Ultrasonic monitors are mounted on the outside, so there are no worries about process separation.

2. Capacitive needles need to go through the tank and make direct touch with the media.

3. Different measurement methods call for different calibration steps.

Maintenance plans take into account differences in how things work. Ultrasonic sensors need to be cleaned every so often to get rid of dust or condensation that has built up. Depending on the properties of the medium, capacitive probes may need to have their coatings removed or their electrodes replaced.

Both technologies are helped by predictive maintenance programs that use constant tracking and sensor fusion to find performance degradation before it happens. If you need to do little maintenance and be able to reach the level meters from afar, then ultrasonic level meters are a better choice for your business.

Application-Specific Selection Criteria

The qualities of the media have a big impact on the choice of technology. Ultrasonic detection works well with most liquids, but not so well with foam, air, or rough surfaces that scatter sound waves.

Capacitive sensors can work with different kinds of media, but they need to be aware of dielectric constants and conductivity levels. Capacitive technology may be better for high-temperature uses because it can handle more heat.

Selection choices are based on needs specific to the industry:

• Ultrasonic designs that are safe from explosions are useful for petroleum uses

• Materials for sensitive probes that are clean are needed for food processing

• Chemical plants prefer ultrasonic housings that don't rust.

• Water treatment plants value the accuracy of non-contact measurements

The difficulty of tank tracking affects the choice of technology. Ultrasonic systems work best for centralized data gathering networks in large storage facilities with many tanks.

Ultrasonic level meters are better suited for multipurpose uses if you need flexible measurement across a variety of media types.

Conclusion

Which ultrasonic level meters or sensitive devices to use relies on the needs of the application, the surroundings, and the goals of the process. Ultrasonic technology is best for measuring things without touching them, has longer ranges, and needs less upkeep. Capacitive sensors, on the other hand, are more accurate for direct-contact situations. By knowing these important differences, you can make decisions that will improve measurement performance and long-term business success.

Partner with GAMICOS for Advanced Ultrasonic Level Meter Solutions

GAMICOS is a top company that sells ultrasonic level meters and has a lot of experience with measuring liquid levels. Our high-tech ultrasonic systems work very well in many different commercial settings. They are backed by strict quality control and foreign standards like CE, RoHS, and ISO compliance.

Some benefits of our ultrasonic level meter are:

• Accuracy to within ±0.1% of full scale thanks to powerful signal processing methods

• Strong construction that can handle tough industrial conditions from -40°C to +80°C

• Wide measurement ranges (0.3 to 40 meters) that allow for different tank setups

• Several ways to communicate, such as 4-20mA, RS485, HART, and Bluetooth choices

• Certified explosion-proof designs for use in dangerous areas

• Real-time echo detection and intelligent noise filtering

• IoT integration features for remote monitoring and predictive maintenance

• Customizable housing materials and mounting configurations for specific applications

• Management of the global supply system to make sure efficient delivery around the world

GAMICOS provides custom ultrasound measurement solutions for companies that make automation equipment, work as engineering contractors, and sell industrial goods in North America, Europe, and the Asia-Pacific area. Their factories are set up for mass production, and they do a lot of research and development.

Our focused technical support team helps you choose the right products, get them installed, and keep them in good shape so that your system works well and is reliable. GAMICOS offers complete ultrasonic level meter options backed by the best experience in the business, whether you're updating old equipment or starting a new automation project.

Are you ready to improve your ability to measure levels? Get in touch with our engineering experts to talk about your needs and find out how GAMICOS ultrasonic technology can help your business run more smoothly. Please email us at info@gamicos.com for a custom advice and the best prices on all of our ultrasound level measurement tools.

References

1. Johnson, M. et al. (2023). "Industrial Level Measurement Technologies: Performance Analysis and Selection Criteria." Journal of Process Control Engineering, Volume 45, Pages 123-138.

2. Chen, L. and Rodriguez, A. (2022). "Comparative Study of Ultrasonic and Capacitive Level Sensors in Chemical Processing Applications." International Conference on Industrial Automation Proceedings, Pages 89-104.

3. Thompson, R. (2023). "Advanced Signal Processing Techniques for Ultrasonic Level Measurement Systems." IEEE Transactions on Industrial Electronics, Volume 70, Issue 8, Pages 7845-7854.

4. Williams, K. et al. (2022). "Reliability Assessment of Level Measurement Technologies in Harsh Industrial Environments." Process Safety and Environmental Protection Journal, Volume 164, Pages 456-467.

5. Anderson, P. and Zhang, H. (2023). "Cost-Benefit Analysis of Level Sensor Technologies for Industrial Tank Monitoring." Industrial Management & Data Systems, Volume 123, Issue 4, Pages 1234-1249.

6. European Committee for Standardization (2022). "Level Measurement Instrumentation Standards and Best Practices." Technical Report EN-50495, Second Edition, Pages 1-78.

_1757930850792.jpg)