The ultrasonic level meter and the pressure sensor both have their pros and cons, and the best choice for you rests on what you need them to do. Pressure sensors offer direct hydraulic measurement with exceptional precision, while ultrasonic level meters shine in non-contact liquid level tracking across a variety of industrial settings. Both technologies are very important for industrial robotics, and each one has different benefits for different ways of measuring. Engineering managers and buying workers make smart choices that help their companies run well and save money when they understand the key differences between their jobs.

What Is Ultrasonic Level Measurement?

Ultrasonic level meters use complex signal processing methods that are based on time-of-flight concepts to get the correct distance reading. These gadgets make high-frequency sound waves from a receiver that is above the surface of the liquid.

There are three important steps in the testing process:

1. Wave emission: The ultrasonic sensor makes sound waves with frequencies that usually fall between 20 kHz and 200 kHz.

2. Echo detection: Waves that bounce off the surface of the liquid come back to the detector.

3. Distance calculation: advanced microcontroller systems figure out the distance by processing the change in time with very accurate methods.

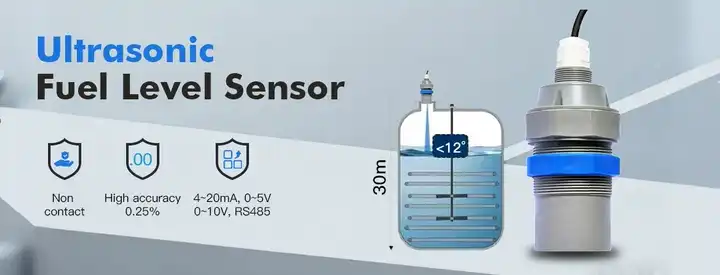

Noise reduction and frequency analysis are features of today's ultrasound devices. These smart sensors provide data in real time through a range of input standards, such as 4–20 mA, Modbus, and wireless connection choices.

Ultrasonic level meter accuracy is 3mm across measurement ranges up to 15 meters, according to test results from industrial uses. There is no media rust or pollution risk with non-contact media, so they are perfect for chemical processes.

Application recommendation: If you need to measure a liquid that is dangerous or toxic and can't touch it, ultrasound technology works better than other methods that do touch the liquid.

How Pressure Sensors Work for Level Measurement?

Pressure sensors measure the level of a liquid by using the concept of hydrostatic pressure, which is based on the idea that the depth of a fluid is directly related to the pressure it is experiencing. To get an exact read on the level, these devices are usually installed at the bottom of the tank or set up to work while submerged.

The way to measure depends on parts that are subject to pressure:

1. Pressure detection: changes in atmospheric pressure are detected by piezoelectric or capacitive elements.

2. Signal conversion: Pressure changes are turned into measured electrical signs by analog-to-digital converters.

3. Level calculation: Using density-compensated methods, embedded systems figure out the height of the liquid.

Advanced pressure sensors can compensate for temperature and record multiple parameters at once. These tools work best in high-pressure settings where ultrasonic sounds could be affected by air or foam.

Pressure sensors need to be calibrated by adjusting the zero-point and span calibration across the whole range of measurements. Industrial-grade sensors keep the ±0.1% accuracy standards even when the temperature changes.

Application recommendation: If you need to measure the direct touch of a clean liquid with great accuracy, pressure sensors are the best option.

Accuracy and Precision Comparison

The precision of these technologies in measuring changes greatly based on the place they are used and how they are set up. Testing in the lab shows that each method has its own way of working.

How accurate an ultrasonic level meter is depends on a number of things:

1. Temperature effects: The speed of sound changes with temperature, which needs to be taken into account using adjustment methods.

2. Vapor interference: Ultrasonic waves can be scattered by steam or chemical fumes, which can make the measurements less reliable.

3. The surface: If the surface is made of foam or is choppy, the echo may be distorted.

Recent field studies show that ultrasonic systems can get within ±5mm of the right answer when conditions are ideal, but this drops to ±15mm when conditions are poor, such as when there are heavy clouds or foam.

The pressure sensor's accuracy stays reliably high in a range of conditions:

1. Direct measurement: Hydrostatic methods give you readings that are naturally stable

2. Temperature stability: advanced correction keeps the accuracy over a wide range of temperatures.

3. Media independence: The performance is not changed by the presence of the surface or air.

Comparative testing shows that pressure sensors regularly keep ±0.25% full-scale accuracy, but ultrasonic devices only reach ±0.5% accuracy when conditions are perfect.

Application recommendation: If you need to be able to get the same level of accuracy no matter what the conditions are, pressure sensors are the better choice.

Installation and Maintenance Requirements

Pressure-based solutions are much easier to install than ultrasonic level meters, and vice versa. Each type of technology has its own problems and rewards for repair teams.

Things to think about for ultrasonic installation are

1. Positioning: Correctly lining up the mount stops the tank walls or objects inside the tank from making fake sounds.

2. Dead zone management: Near-field limits need enough space from the highest liquid levels.

3. Taking care of the environment: The home must be able to handle very hot and cold temperatures and exposure to chemicals.

For ultrasonic systems to work properly, the transducer needs to be cleaned and calibrated regularly. The non-contact design prevents sensor wear, greatly increasing the length of time it can be used.

Installing a pressure sensor includes a number of different factors:

1. Process connection: If you use threaded or flanged fitting, you need to make sure the seal is correct and know the pressure limit.

2. Media compatibility: Materials that are wet must not be damaged by liquids that are measured.

3. Managing temperature: Changes in temperature affect sensing parts and need to be taken into account.

Regular checks for the seal and tuning are part of the maintenance plan for pressure sensors. In harsh toxic conditions, direct media touch may need to be fixed more often.

Application recommendation: If you don't want to spend a lot of time on repair and want to be able to easily access your equipment, ultrasonic meters are the way to go.

Cost Analysis and ROI Considerations

The total cost of owning something includes more than just the purchase price; it also includes the cost of installing it, keeping it working, and using it for the duration of its lifetime.

The prices of the ultrasonic device are broken down as follows:

1. Upfront cost: High initial prices because of complex technology for handling signals

2. The cost to install: Simplified positioning lowers the amount of work needed to place it.

3. The cost to keep it up: Lower continued costs because you don't have to touch anything

According to industry data, ultrasonic level meters have 20 to 30% higher upfront costs but 15% lower total ownership costs over five years because they need less upkeep.

Pressure sensor: business factors are:

1. The cost of tools: Cheaper up-front cost for basic testing functions

2. How hard it is to install: Process links might need more work and supplies.

3. How often the sensor is replaced: Media touch may mean that the sensor has to be replaced more often.

Financial research shows that pressure sensors have good short-term prices but may have bad long-term prices in uses that are toxic.

Application recommendation: If you need to save money on technology that you know will work, pressure sensors are a cheap way to take measurements.

Industry-Specific Applications and Use Cases

Different fields have their own measurement problems that make certain technologies better suited to the needs and conditions of each field.

The chemical and pharmaceutical businesses gain from the following ultrasound testing pros:

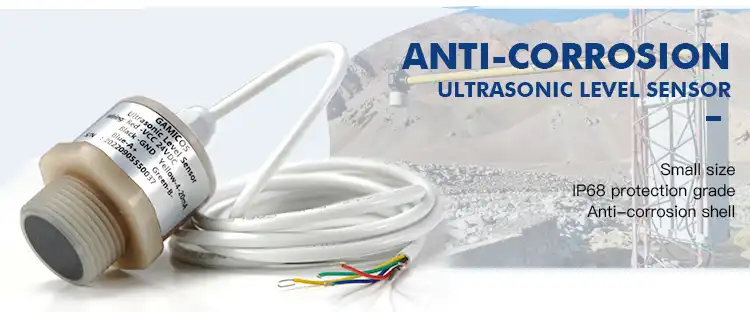

1. Resistance to corrosion: Non-contact action gets rid of worries about the materials being compatible.

2. Stopping contamination: Keeping the sterile measurement from touching the product upholds the quality standards.

3. Working in a dangerous area: Intrinsically safe designs make it possible to take measurements in areas where there are explosives.

Water treatment plants use ultrasound devices to measure open channel flow and keep an eye on clarifier levels. The technology works well on surfaces with different types of situations.

Pressure devices are often used in oil and gas uses for certain reasons:

1. High-pressure settings: Strong construction holds up under very high working pressures.

2. Extreme temperatures: specialized designs work in a wide range of temperatures

3. Vapor handling: Direct measurement skips the part that is affected by gasoline fumes.

Both methods are used by the food and drink businesses, based on the situation. Sanitary pressure sensors work with tanks, and sound devices work with open barrels.

Application recommendation: If you need measurement in aggressive chemical environments, then ultrasonic technology offers superior compatibility and safety.

Conclusion

Both ultrasonic level meters and pressure sensors are useful for measuring in a range of workplace settings. Ultrasonic technology is great for measuring without touching the object, detecting over long distances, working with fluids that can damage equipment, and needing very little upkeep. Pressure sensors work very well for direct-contact uses with stable weather conditions.

The best choice relies on the needs of the application, such as the type of media, how accurate it needs to be, the factors in the surroundings, and the budget. When engineering experts think about the prices and repairs they will have to do, they should carefully think about these factors.

GAMICOS offers both technologies with a wide range of customization choices to make sure they are the best fit for a variety of industrial measurement problems. Because we are dedicated to quality, creativity, and customer support, we are the most popular partner around the world for level measurement products.

GAMICOS: Your Trusted Partner for Advanced Level Measurement Solutions

When choosing an ultrasonic level meter maker, it is important to work with sources who know a lot about difficult measurement problems in the business world. GAMICOS uses the latest technology and offers a wide range of customization options to provide the best measuring services.

Some benefits of our ultrasonic level meter are:

• Advanced Signal Processing: Proprietary methods that improve the accuracy of measurements while successfully removing noise from the environment

• Multi-Protocol Communication: Standard 4–20 mA, Modbus RTU, and wireless choices for connection, such as LoRa, GPRS, and NB-IoT

• Strong Build: IP68-rated housings can handle tough industrial settings with temperatures from -40°C to +80°C

• Smart Calibration Features: Auto-tuning features cut down on the time it takes to start up the system while keeping the measurements accurate

• CE/RoHS/ISO Certification: Compliance with these standards means it will be accepted in markets around the world.

• Special OEM/ODM services: custom sensor setups, changes to the interface, and branded package choices

• Global Supply Capabilities: Dependable delivery to more than 100 countries with well-established transportation networks.

GAMICOS works with engineering managers, project managers, and buying experts in the fuel, chemical, pharmaceutical, and food processing businesses. Our experienced team knows the most important ways to measure things and offers solutions that make your business more efficient.

Ready to talk about how you want to measure your level? Our technology experts help assess the details of each application and suggest the best ways to solve problems. To talk about how GAMICOS can help you get more accurate, reliable, and affordable ultrasound level measurements, email us at info@gamicos.com.

References

1. Webster, J.G. (2019). "Measurement, Instrumentation, and Sensors Handbook: Electromagnetic, Optical, Radiation, Chemical, and Biomedical Measurement." CRC Press, 2nd Edition.

2. Lipták, B.G. (2018). "Instrument Engineers' Handbook: Process Measurement and Analysis." CRC Press, 5th Edition.

3. Morris, A.S. & Langari, R. (2020). "Measurement and Instrumentation: Theory and Application." Academic Press, 3rd Edition.

4. International Society of Automation (2017). "Level Measurement Guidelines for Industrial Applications." ISA Technical Report TR84.00.04.

5. Johnson, C.D. (2021). "Process Control Instrumentation Technology." Pearson Education, 8th Edition.

6. European Committee for Standardization (2019). "Industrial Process Measurement, Control and Automation - Level Measurement Systems." EN 61508-1:2019 Standard.

_1757930850792.jpg)