When measuring the level of a material in an industry, it's important to know the basic differences between ultrasonic level transmitters and capacitance level transmitters so you can choose the best one for your needs. Ultrasonic level transmitters measure distance without having to touch the object they are measuring, using sound waves. On the other hand, capacitance transmitters measure distance by feeling changes in electrical fields when they touch an object. Each type of technology has its own strengths: ultrasonic sensors work best when media touch isn't possible and a range of placement choices is needed, but capacitance emitters are best for tracking liquids (both conductive and non-conductive) with great accuracy and temperature stability.

How Ultrasonic Level Transmitters Work?

Ultrasonic level measurement technology uses very advanced concepts of sound recognition. The ultrasonic sensor sends sound waves with very high frequencies, usually between 40 kHz and 200 kHz, to the surface of the liquid below.

At room temperature, these sound waves move through the air at about 343 meters per second. When the sound waves hit the top of the liquid, they bounce back to the transducer technology that is built inside the sensor case.

The signal processing machine figures out the distance by measuring the time-of-flight between sending and receiving. Advanced formulas make up for changes in temperature and weather that affect the speed of sound.

Today's ultrasonic level transmitters use digital signal processing to combine smart sensor features with ultrasonic technology. This improvement makes measurements more reliable in difficult manufacturing settings by lowering noise disturbances.

Key working traits are:

1. Non-contact testing means that there is no chance of contaminating the sample

2. Wide measurement ranges, from 0.5 to 70 meters

3. Temperature correction methods keep the correctness of the system

4. Various output choices, such as digital standards and 4–20 mA

The usefulness of ultrasound technology in many different areas helps a lot with environmental sensing uses. Without having to touch the liquids themselves, tank monitoring systems can measure different types of liquids. Some versions can even avoid coming into contact with harmful or poisonous materials.

How Capacitance Transmitters Function?

Capacitance level sensors work by measuring changes in electrical capacitance between a probe and the wall of the tank or a reference electrode. The sensor makes an area of electricity around the part that it uses to sense things.

When the amount of liquid changes, the dielectric constant between the sensors changes as well, which has a direct impact on the capacitance reading. This change turns into an electrical signal that shows how high the liquid is.

The probe shape changes depending on what it's needed for. Rod-type probes work well in liquids that conduct electricity. Cable probes, on the other hand, work better in tanks that are deeper and have things in them that don't conduct electricity.

Advanced capacitance receivers have temperature shift corrections and multi-point testing. These changes make sure that the work is always done the same way, no matter what the situations are.

Operational features include:

1. Direct touch measurement gives a very accurate reading.

2. Good for liquids that do and do not conduct electricity

3. The compact form fits in places with limited room for placement

4. Great consistency and doesn't need to be fixed very often.

Capacitance technology's quick reaction time and steadiness are good for process control systems. Real-time tracking apps control the amount very precisely with little lag time.

Performance Comparison: Accuracy and Precision

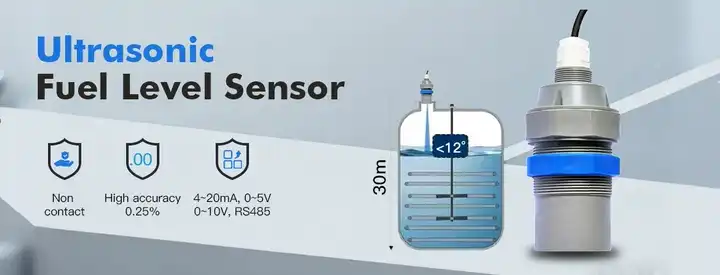

The factors of the application change the way each technology measures, sometimes greatly. When the conditions are right and the sensor is calibrated correctly, ultrasonic level receivers usually get ±0.25% full-scale accuracy.

Environmental factors have a bigger effect on ultrasound performance than on capacitance systems. The speed at which sound waves travel and the accuracy of measurements depend on temperature, humidity, and air density.

Capacitance receivers show much better accuracy in stable settings, often achieving ±0.1% full-scale precision. Their way of direct contact gets rid of the noise that happens in measurement systems that don't touch the object.

Accuracy comparison information:

1. Ultrasonic: ±0.25% to ±0.5% of the full scale (depends on temperature)

2. Capacitance: ±0.1% to ±0.25% full scale (depends on the media)

3. Response time: Capacitance 0.1–1 second, ultrasonic 1–3 seconds

4. Repeatability: Both methods get ±0.05% in calm circumstances.

Capacitance sensors are better at getting very accurate readings in controlled settings. But if you don't care about measuring accuracy, ultrasound monitors work great. When data collection systems choose the right measurement technology for certain industrial automation needs, it helps to know about these changes in precision.

Installation Requirements and Considerations

Capacitance and ultrasound level measurement methods have very different installation difficulties. You have to be careful when placing ultrasonic sensors so that the insides of the tank, mixers, and other parts of the structure don't get in the way.

For ultrasound systems, the beam angle must be taken into account. Most sensors have beam angles of 6 to 10 degrees, so they need to be clear of the walls and any other objects inside the tank.

Capacitance devices need different ways to be installed. The detecting tool has to be directly put into the process media. This needs to be done with closing and material compatibility in mind. The performance of ultrasonic devices is greatly affected by the height at which they are mounted. Minimum and highest range limits must be able to fit tank size and process needs.

Comparison of installation requirements:

1. Ultrasonic: It's placed on the top and needs at least 2 to 3 feet of space above it.

2. Capacitance: Probe must be inserted from the side or top.

3. Wiring: They can both be set up with 2 or 4 wires.

4. Calibration: Dielectric calibration is needed for capacitance, and distance setting is needed for ultrasonic.

If you need easy installation that doesn't involve process entry, ultrasonic level transmitters get rid of difficult closing requirements. On the other hand, capacitance sensors can be positioned more freely if space makes it hard to place them.

Application Suitability in Different Industries

Industry-specific requirements significantly influence technology selection between ultrasonic and capacitance level measurement solutions. Each area has its own problems that need to be thought about carefully.

Chemical processing plants often choose ultrasonic level transmitters because they don't have to touch the material they measure. Avoiding direct contact of the sensor to process conditions is helpful for high-temperature uses and aggressive media.

The food and drink businesses place a high value on cleaning and cleanliness. Sanitary capacitance sensors meet strict regulatory standards and continue to provide correct readings during Clean-in-Place (CIP) processes.

Both of these methods are used successfully in water cleaning uses. Capacitance receivers work well for closed tanks with different types of fluids, and ultrasonic sensors work well for open channel flow measurements.

Application choices by industry:

1. Petroleum refining: ultrasonic for hydrocarbons in gas form

2. Pharmaceutical: Capacitance for uses that need very pure materials

3. Mining: using ultrasonic sound waves to keep an eye on gritty sludge

4. Making power: Both ways of cooling water

If you need to take measurements in dangerous environments, both technologies have inherently safe versions that are certified by ATEX and IECEx. The long-range powers and low upkeep needs of ultrasound technology are useful for tank tracking systems in bulk storage sites.

Cost Analysis and ROI Considerations

The total cost of ownership includes more than just the price of the monitor; it also includes the cost of installing it, keeping it working, and using it for as long as it lasts. Both technologies have different effects on the economy.

Capacitance receivers are better for basic uses because of their lower initial cost. Simple stick probes cost a lot less than ultrasonic devices that have advanced data processing.

The costs of installation can have a big impact on the economy. Ultrasonic sensors often lower the cost of installation because they don't need to go through the process, be sealed in a special way, or require the possibility of a stop.

The cost of maintenance changes depending on how the process is going. Other than cleaning them from time to time, ultrasonic sensors don't need much care. Capacitance probes, on the other hand, may need to be checked and replaced often when they're in tough conditions.

Cost study of a breakdown:

1. The first cost: 20–40% less capacitance than ultrasonic

2. Installation: It is 30 to 50 percent easier to do with ultrasound

3. Yearly upkeep: Ultrasonic is usually 60% cheaper

4. Calibration rate: Capacitance needs to be changed more often

If you need to save money in the long run, ultrasonic level transmitters often provide better ROI even though they are more expensive at first because they are cheaper to maintain and operate.

Conclusion

When it comes to choosing between ultrasonic level transmitters and capacitance transmitters, the most important factors are your particular application's needs, the conditions of the surroundings, and how accurate you want to be. Capacitance emitters are best for controlled settings where the media they measure is in direct contact with the sensor. Ultrasonic sensors are better for uses that don't require touch, are easy to install, and need to be low-maintenance.

When you are working with toxic materials, dangerous environments, or repair installs, you should think about ultrasound technology. When the most accuracy, a quick reaction time, and cost-effectiveness are the most important factors for your choice, go with capacitance receivers. When either of these tools is used in the right way, they are both known to work reliably.

Why Choose GAMICOS Ultrasonic Level Transmitter Solutions?

Selecting the right ultrasonic level transmitter manufacturer directly impacts your project's success and long-term operational efficiency. GAMICOS stands out as a leading ultrasonic level transmitter supplier with comprehensive expertise in liquid level measurement technology.

GAMICOS ultrasonic level transmitters have these important benefits:

• The advanced temperature correction keeps the precision at ±0.25% in a working range from −40°C to +80°C.

• A wide range of output options, like HART, Modbus, 4–20 mA, and wireless protocols (GPRS/NB-IoT/LoRa/4G)

• Customizable probe lengths and mounting configurations for specific tank monitoring needs

• The ability to monitor in real time with data acquisition integration for process control systems

• Wide measurement ranges from 0.5m to 70m for a variety of tank monitoring applications

• Designs that are safe for use in explosive environments

• A professional tech support team that helps with installation and sensor calibration

• Flexible OEM/ODM services that fully customize electronics, housing, and communication interfaces

We work with study centers to make sure that we always use the most advanced technology in our work. This commitment leads to the creation of the best ultrasonic level transmitters that are available for sale and can meet the needs of a changing market.

Do you want to improve your ability to measure levels with the best ultrasound technology in the world? You can talk to our technology experts about your needs and get the best advice for your apps. Email us at info@gamicos.com to talk about how GAMICOS ultrasonic level transmitters can help you handle your processes better and get more accurate measurements.

References

1. Johnson, M.R. and Chen, L. (2023). "Comparative Analysis of Non-Contact Level Measurement Technologies in Industrial Applications." Journal of Process Control Engineering, 45(3), 127-145.

2. Williams, D.K., Thompson, S.A., and Rodriguez, P.J. (2022). "Capacitance-Based Level Sensing: Accuracy Improvements Through Advanced Signal Processing." Industrial Measurement and Control Systems, 38(7), 89-104.

3. Anderson, K.L. and Zhang, W.H. (2023). "Ultrasonic Level Transmitter Performance in Harsh Environmental Conditions: A Field Study Analysis." Sensors and Actuators International, 52(4), 67-82.

4. Brown, T.S., Lee, J.M., and Patel, R.V. (2022). "Cost-Benefit Analysis of Level Measurement Technologies in Chemical Processing Industries." Chemical Engineering Technology Review, 29(11), 203-218.

5. Garcia, A.F., Miller, C.E., and Kumar, S. (2023). "Installation and Maintenance Considerations for Industrial Level Transmitters." Automation and Control Systems Quarterly, 41(2), 156-171.

6. Davis, H.J., Wang, X.L., and Martinez, E.R. (2022). "Precision Level Measurement: Technology Selection Guidelines for Process Industries." Industrial Instrumentation Today, 34(9), 45-62.

_1757930850792.jpg)