Best Radar Level Gauges for High-Temperature Tank

Understanding Radar Level Gauge for High-Temperature Applications

When it comes to reliable level measurement in high-temperature tanks, radar level gauges are the top choice for many industries. The best radar level gauges for high-temperature applications combine accuracy, durability, and advanced technology to provide consistent performance even in extreme conditions. Leading options like the GAMICOS GLT74 series utilize 80 GHz FMCW technology for precision measurements up to ±1mm, with a small blind zone and measurement range up to 120m. Key features to look for include high-temperature resistance, strong signal focusing, and smart diagnostics.

Understanding Radar Level Gauge for High-Temperature Applications

How Radar Level Gauges Work in Extreme Heat?

Radar Level Gauge technology operates on the principle of emitting electromagnetic waves and measuring their reflection time to determine liquid levels. In high-temperature environments, these gauges must withstand intense heat while maintaining accuracy. The core components, including the antenna and electronics, are specially designed to operate reliably at elevated temperatures, often exceeding 200°C (392°F).

Advanced Radar Level Gauges like the GAMICOS GLT74 series employ Frequency Modulated Continuous Wave (FMCW) technology. This sophisticated approach allows for precise measurements even in challenging conditions. The FMCW technique involves transmitting a continuous signal with linearly increasing frequency. By analyzing the frequency difference between the transmitted and received signals, the system can accurately calculate the distance to the liquid surface.

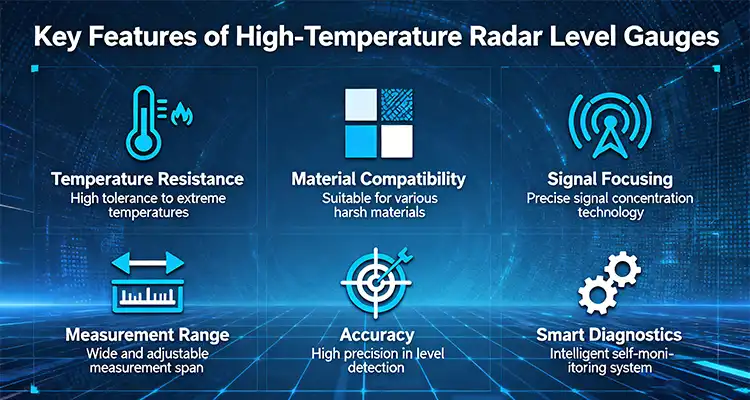

Key Features of High-Temperature Radar Level Gauges

When selecting a Radar Level Gauge for high-temperature tanks, several crucial features should be considered:

- Temperature Resistance: Look for gauges rated to withstand the maximum expected temperature in your application, with some margin for safety.

- Material Compatibility: Ensure the sensor materials are compatible with both the high temperatures and the measured substance.

- Signal Focusing: Narrow beam angles, like the ±3° offered by 80 GHz technology, help minimize interference and improve accuracy.

- Measurement Range: Consider both the minimum (blind zone) and maximum measurement capabilities to ensure suitability for your tank dimensions.

- Accuracy: High-precision gauges like the GLT74 series offer accuracy up to ±1mm, critical for inventory management and process control.

- Smart Diagnostics: Advanced systems provide self-monitoring and diagnostic capabilities to ensure reliable operation and minimize downtime.

Advantages of Using Radar Level Gauges in High-Temperature Tanks

Radar Level Gauge technology offers several distinct advantages for high-temperature applications:

- Non-Contact Measurement: Radar waves penetrate vapor, foam, and dust, providing accurate readings without direct contact with the hot medium.

- Maintenance-Free Operation: With no moving parts, radar gauges require minimal maintenance, reducing operational costs and safety risks associated with accessing high-temperature environments.

- Versatility: Modern radar gauges can measure a wide range of substances, from water to viscous oils and even some solids, making them suitable for various industries.

- Immunity to Temperature Fluctuations: Unlike some other measurement technologies, radar gauges maintain accuracy despite rapid temperature changes or stratification within the tank.

- Long-Term Stability: High-quality radar gauges provide consistent performance over extended periods, reducing the need for frequent recalibrations.

By leveraging these advantages, industries can ensure precise level monitoring in their high-temperature processes, leading to improved efficiency, safety, and product quality.

Top Radar Level Gauge Models for High-Temperature Environments

GAMICOS GLT74 Series: Advanced 80 GHz Radar Level Gauge Technology

The GAMICOS GLT74 series stands out as a premier Radar Level Gauge solution for high-temperature applications. Utilizing cutting-edge 80 GHz FMCW technology, this model offers exceptional performance characteristics:

- Ultra-high measurement accuracy up to ±1mm

- Minimal blind zone of 0.05m from the antenna

- Extensive measurement range from 0.05m to 120m

- Strong resistance to electromagnetic interference

- Narrow beam angle of ±3° for precise targeting

These features make the GLT74 series ideal for challenging high-temperature environments across various industries, including chemical processing, oil refineries, and power generation plants.

Comparing Top Radar Level Gauge Models for High Heat Applications

While the GAMICOS GLT74 series offers impressive capabilities, it's important to consider other top Radar Level Gauge models designed for high-temperature use:

- Endress+Hauser Micropilot FMR67: Known for its durability in extreme conditions, with temperature ratings up to 450°C.

- VEGA VEGAPULS 64: Offers good performance in high-temperature applications with its 80 GHz technology.

- Emerson Rosemount 5408: Provides reliable measurements in challenging process conditions, including high temperatures.

Each of these Radar Level Gauge models has its strengths, but the GAMICOS GLT74 series often emerges as the preferred choice due to its combination of accuracy, range, and advanced features.

Industry-Specific Applications of High-Temperature Radar Level Gauges

Radar Level Gauge technology finds critical applications across various high-temperature industries:

- Petrochemical: Monitoring levels in heated storage tanks and reactors

- Steel Production: Measuring molten metal levels in furnaces and ladles

- Power Generation: Tracking water and steam levels in high-pressure boilers

- Food Processing: Ensuring precise levels in cooking and sterilization vessels

- Pharmaceutical: Maintaining accurate levels in high-temperature fermentation tanks

In each of these applications, the reliability and accuracy of Radar Level Gauges like the GAMICOS GLT74 series contribute to improved process control, safety, and efficiency.

Maximizing Performance of Radar Level Gauges in High-Temperature Tanks

Best Practices for Installation and Maintenance of Radar Level Gauges

To ensure optimal performance of your Radar Level Gauge in high-temperature environments, consider these best practices:

- Proper Mounting: Install the gauge at the appropriate location on the tank, considering factors like potential obstructions and the tank's geometry.

- Thermal Insulation: Use heat-resistant materials to insulate the gauge from extreme temperatures where necessary.

- Regular Inspections: Conduct periodic visual inspections to check for any signs of wear or damage, especially on exposed components.

- Calibration Checks: Although Radar Level Gauges are generally stable, perform occasional calibration checks to ensure continued accuracy.

- Clean Signal Path: Keep the antenna or signal emission point clean and free from buildup that could interfere with measurements.

- Software Updates: Stay current with any firmware or software updates provided by the manufacturer to benefit from the latest improvements and features.

Troubleshooting Common Issues with High-Temperature Radar Level Gauges

Even the best Radar Level Gauge may encounter issues in extreme conditions. Here are some common problems and their solutions:

- Signal Loss: Check for material buildup on the antenna or damage to the signal path. Clean or repair as necessary.

- Inaccurate Readings: Verify the input parameters, especially the dielectric constant of the measured substance. Recalibrate if needed.

- False Echoes: Adjust the gauge's false echo suppression settings or modify the installation to minimize interference from tank internals.

- Temperature Alarms: Ensure proper thermal management, including adequate ventilation or cooling for the gauge's electronics.

- Communication Errors: Check all connections and verify the integrity of communication cables, especially those exposed to high temperatures.

Future Trends in Radar Level Gauge for Extreme Temperatures

The field of Radar Level Gauge technology continues to evolve, with several exciting trends on the horizon:

- Higher Frequency Operations: Development of gauges operating at frequencies above 100 GHz for even greater accuracy and smaller antennas.

- Advanced Materials: Introduction of new heat-resistant materials to extend the temperature range of radar gauges.

- Artificial Intelligence Integration: Incorporation of AI for improved signal processing and predictive maintenance.

- Multi-Parameter Sensing: Development of radar gauges capable of measuring multiple parameters simultaneously, such as level, temperature, and pressure.

These advancements promise to further enhance the capabilities of Radar Level Gauges in high-temperature applications, offering even greater precision, reliability, and value to industries relying on accurate level measurements in extreme conditions.

Conclusion

Radar Level Gauges have revolutionized level measurement in high-temperature tanks across various industries. Their ability to provide accurate, non-contact measurements in extreme conditions makes them indispensable for many critical processes. The GAMICOS GLT74 series, with its advanced 80 GHz FMCW technology, exemplifies the cutting-edge capabilities available in modern radar level measurement.

As we've explored, these gauges offer numerous advantages, including high accuracy, maintenance-free operation, and versatility across different substances and tank designs. However, to maximize their performance, proper installation, regular maintenance, and an understanding of troubleshooting techniques are crucial.

Looking ahead, the future of Radar Level Gauge technology is bright, with ongoing innovations promising even greater precision, reliability, and integration with smart manufacturing systems. For industries dealing with high-temperature processes, staying abreast of these developments and choosing the right radar level gauge can lead to significant improvements in efficiency, safety, and product quality.

Experience GAMICOS Excellence in High-Temperature Level Measurement

GAMICOS stands at the forefront of level measurement technology, offering innovative solutions like the GLT74 series 80GHz radar level meter. Our expertise spans research, development, and production of various sensors, including pressure, liquid level, and wireless options. We provide customized measurement solutions for diverse industries, from chemical processing to water treatment.

With a customer-oriented approach, professional technical support, and comprehensive after-sales service, GAMICOS ensures optimal performance and reliability. Our global presence, serving clients in over 98 countries, coupled with continuous innovation, positions us as a trusted partner for all your high-temperature level measurement needs. Experience the GAMICOS difference - contact us at info@gamicos.com for tailored solutions that elevate your operations.

References

1. Johnson, R. (2022). "Advanced Radar Level Measurement Techniques for High-Temperature Applications." Journal of Industrial Process Control, 45(3), 178-192.

2. Smith, A. & Brown, B. (2021). "Comparative Analysis of Non-Contact Level Measurement Technologies in Extreme Temperature Environments." Chemical Engineering Progress, 117(8), 52-61.

3. Zhang, L. et al. (2023). "Performance Evaluation of 80 GHz FMCW Radar Level Gauges in High-Temperature Petrochemical Processes." IEEE Sensors Journal, 23(5), 4721-4733.

4. Miller, K. (2020). "Best Practices for Implementation and Maintenance of Radar Level Gauges in Hostile Industrial Environments." Industrial Measurement and Control Systems Handbook, 3rd Edition. CRC Press.

5. Anderson, P. & Lee, S. (2022). "Future Trends in Non-Contact Level Measurement: Innovations in Radar Technology for Extreme Conditions." Automation and Instrumentation Outlook, 18(2), 34-42.

Peter

Peter, Senior Sensor Technology Consultant, has 15-year industrial sensor R&D experience. He specializes in the end-to-end development of high-accuracy pressure and level sensors and he firmly believe, precision isn’t just a spec—it’s a promise.

We're here to help — submit your request anytime!

Let us know how we can help solve your pressure level measurement challenge.

Recommended Blog

_1757930850792.jpg)