Why Every Water Pump Needs a Reliable Level Sensor

Comprehending Well Level Sensors and Their Critical Role in Water Pumps

- Comprehending Well Level Sensors and Their Critical Role in Water Pumps

- Comparing Leading Well Level Sensor Technologies for Optimal Water Pump Performance

- Installation, Calibration, and Maintenance Best Practices for Reliable Sensor Operation

- Overcoming Common Challenges and Enhancing Sensor Performance

- Procurement Guide: Finding and Buying the Right Well Level Sensor for Your Business

- Conclusion

- FAQ

- Partner with GAMICOS for Superior Well Level Sensor Solutions

- References

Many industrial processes, from chemical plants to farm irrigation networks, depend on water pump systems to keep them running. When a well level sensor is added to these systems, simple pumping tasks become complex, automated processes that avoid costly failures and improve business efficiency. Without proper level tracking, water pumps are always at risk of dry-running, which can damage them badly in minutes and require expensive fixes and a lot of downtime that affects whole production lines.

Comprehending Well Level Sensors and Their Critical Role in Water Pumps

The Foundation of Modern Pump Control Systems

In the past ten years, water level measurement technology has changed a lot. Today's devices are more accurate and reliable than ever before. A well level sensor works on the basic idea that the hydrostatic pressure stays the same for all levels of liquid. When placed at certain depths in liquids, these sensors use the formula P = ρ × g × H + Po to turn pressure readings into accurate level readings. Each variable helps to get an accurate reading of the liquid level.

More and more, companies that make industrial automation tools are realizing that pump safety is more than just on/off controls. Recent studies in the industry say that predictive maintenance strategies can cut unexpected downtime by up to 40%. This is because advanced level sensors can watch things all the time. These sensors work perfectly with current automation systems. They send data in real time, which helps engineering managers make smart choices about how to improve systems and when to do repairs.

Preventing Costly Pump Failures Through Intelligent Monitoring

When a pump runs dry, it causes more problems than just damage to the equipment. When pumps work without enough liquid in them, too much heat builds up inside them, damaging the seals, impellers, and motors until they stop working. Industrial pumps can cost anywhere from tens of thousands to hundreds of thousands of dollars to replace. This doesn't include the money lost on production and the cost of emergency repairs.

Modern underwater level sensors, like the GLT530 series, are built to last with fully welded covering that keeps them accurate even after being submerged for a long time. These sensors can measure from 0 to 200 meters below the surface of the water and have very high accuracy rates of ±0.25%FS, so they can be used for a wide range of security needs. The small probe diameters, which range from 16mm and 19mm, allow setups with limited room while still providing professional-level performance.

| GLT530 Deep Well Level Sensor | |

| Pressure range | 0~1m ... 200m H2O |

| Over pressure | 150%FS |

| Burst pressure | 300%FS |

| Output signal | 4~20mA,0~5VDC, Customizable |

| Power supply | 10~30VDC |

| Accuracy | 0.25%, 0.5% |

| Long-term stability | ≤0.1%FS/year |

| Operating temperature range | -20~+85 °C |

| Material of pressure membrane | 316LSS |

| Material of housing | Stainless stee 304 |

| Response time(10%~90%) | 10ms |

| Protection | IP68 |

Comparing Leading Well Level Sensor Technologies for Optimal Water Pump Performance

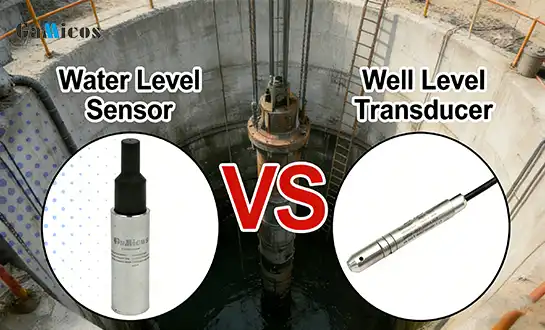

Pressure-Based Sensors: The Gold Standard for Reliability

Industrial uses mostly use hydrostatic pressure sensors because they are very accurate and have been shown to be reliable. These sensors check how heavy the columns of liquid are above the detecting element. They do this by turning changes in pressure into electrical signs that pump control systems understand as changes in level. The technology works great in situations that need to be monitored all the time because it stays steady even when temperatures change and there are problems in the surroundings.

Pressure-based sensors are often recommended by engineering companies for important tasks because they work consistently no matter the liquid's properties or the surface's state. Ultrasonic sensors may have trouble with foam or gas distortion, but pressure sensors can reliably measure things even in tough conditions. The non-polar two-wire current output design makes connecting easier and lowers the number of places where control circuits could fail.

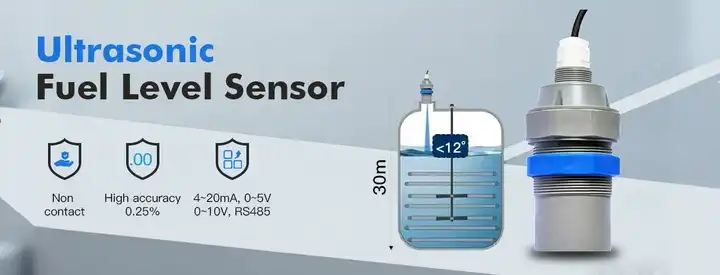

Ultrasonic Technology: Non-Contact Solutions for Specialized Applications

Ultrasonic level sensors are better in situations where direct touch with liquid is difficult. These sensors send out high-frequency sound waves that bounce off of wet surfaces and are used to figure out how far away something is by measuring the time it takes to travel. Ultrasonic technology works very well in clean areas, but things like temperature differences, the presence of air, and surface movement can make measurements less accurate, so it's important to be aware of these issues.

Often, the choice between pressure and ultrasonic sensors relies on the needs of the application and the conditions of the surroundings. When choosing the right sensor technologies, procurement managers need to think about things like how hard they are to install, how easy they are to maintain, and how reliable they will be in the long run. Professional technical support teams can help you choose the best sensor based on a thorough study of your application and your performance needs.

Wireless Monitoring Systems: Advancing Remote Pump Management

IoT integration makes wireless level tracking a big step forward in automating pump systems because it lets managers and collectors of data work from afar. These systems get rid of the need for a lot of wiring while still letting you watch setups that are spread out in real time. Remote pump stations can be monitored with wireless sensors that use Lora, GPRS, NB-IoT, or 4G transmission methods. This is possible without having to spend a lot of money on new infrastructure.

When putting in place wireless tracking systems, contact range, battery life, and the reliability of data transfer must all be carefully thought through. Modern wireless sensors have improved power management features that make them last longer while keeping the connection reliable. These systems are especially useful for uses in remote areas where standard wiring isn't possible or wouldn't be cost-effective.

Installation, Calibration, and Maintenance Best Practices for Reliable Sensor Operation

Strategic Site Assessment and Proper Sensor Placement

A thorough site survey that evaluates factors such as the properties of the liquid, its flow patterns, and the surrounding environment is the first step to a successful well level sensor installation. This ensures that the sensor is placed in an optimal location for accurate measurements, accounting for potential interference from nearby structures, temperature variations, or fluid dynamics in the well. Where level sensors are placed has a big effect on how accurate measurements are and how reliable they are over time. Place sensors away from areas with a lot of movement, like those made by inlet lines or agitation equipment, to get accurate readings and keep the sensors from getting damaged by trash or changes in the flow.

Professional installation teams say that sensors should be mounted at least three pipe lengths away from where the fluid enters the system to reduce the effects of noise. The small size of the GLT530 sensor makes it easier to place in tight areas, and its strong construction means it can handle rough operating conditions. Choosing the right fitting tools and managing cables properly can help keep your equipment reliable for a long time in harsh industrial settings.

Precision Calibration Protocols for Optimal Performance

Procedures for calibration set the stage for accurate level readings throughout the sensor's useful life. Setting zero and span points that match to an empty and full tank is part of the initial adjustment. For this process to work, exact reference readings must be made, and environmental factors that could affect how well the sensor works during calibration must be carefully considered.

Verifying the calibration on a regular basis keeps measurements accurate and finds possible drift problems before they affect the system's performance. Best practices in the industry say that important applications should have their calibration checked every three months, and that trained technicians should do full calibrations once a year. Keeping track of the results of calibrations is important for legal compliance and predictive maintenance plans.

Proactive Maintenance Strategies for Extended Sensor Life

Maintenance tools that work well keep sensors working longer and keep their accuracy. Sensor housings should be visually checked, wire integrity should be checked, and electrical connections should be confirmed as part of regular inspection plans. Cleaning methods get rid of buildups of dirt or grime that might lower the sensor's performance, especially in situations where chemical precipitates or floating solids are present.

Modern sensors have built-in advanced diagnostic tools that allow state tracking that finds problems before they become system breakdowns. These features let you know early on when sensors are losing their effectiveness, so you can schedule repair work that doesn't interrupt operations too much. Diagnostic data can be accessed directly by maintenance teams, which improves service plans and cuts down on the need for on-site visits.

Overcoming Common Challenges and Enhancing Sensor Performance

Addressing Signal Interference and Environmental Factors

There are many problems that can happen in industrial settings that can affect how well sensors work. These include electromagnetic interference, changes in temperature, and chemical exposure. Modern sensors have signal filtering circuits built in that filter out electrical noise and keep output signals stable even in rough circumstances. When you ground your equipment properly and protect your cables, interference from nearby electrical equipment and variable frequency drives is kept to a minimum.

Temperature adjustment methods change well level sensor outputs automatically to take into account how temperature changes can affect the accuracy of measurements. This function is especially useful in situations where there are big changes in temperature that could cause measurement mistakes otherwise. Professional-grade monitors that have been certified by CE, RoHS, and ATEX make sure that they meet international safety and environmental standards.

Leveraging Advanced Sensor Technologies for Enhanced Reliability

Level tracking systems of the future will use smart sensor technologies that can connect to the internet of things and do predictive analytics. These high-tech sensors constantly check their own functionality, make sure they are calibrated correctly, and send out maintenance warnings that help the system work better. Machine learning systems look at past performance data to find trends that show when something might go wrong before it does.

When smart monitoring systems are used in the real world, they make operations more efficient and lower the cost of upkeep. Chemical processing plants say that unexpected repair events have dropped by up to 25% since smart sensors were put in place. These systems let you use condition-based repair plans that make the best use of resources while still meeting high standards for uptime.

Case Studies: Quantifiable Benefits in Industrial Applications

A big pharmaceutical factory put in place advanced level tracking for all of their water treatment systems. This cut the cost of pump upkeep by 30% and made the factory more in line with regulations. Adding wireless tracking made it possible to keep an eye on important processes from afar, which cut down on the need for site inspections while still allowing for operational awareness.

Applications in the energy sector show how important it is to have accurate level tracking to protect expensive equipment. By installing full level tracking systems, a petrochemical processing plant saved $2.3 million in pump repair costs over the course of three years. These results show what a big return on investment is possible if you choose and set up sensors correctly.

Procurement Guide: Finding and Buying the Right Well Level Sensor for Your Business

Evaluating Suppliers and Technology Partners

To find the right sensor providers, you need to carefully consider their technical skills, customer service, and the possibility of forming a long-term relationship. Leading providers show their skill by having a wide range of products, a lot of experience in the field, and a history of success in tough situations. GAMICOS is a great example of these traits because they specialize in solutions for measuring liquid level and pressure and serve customers in over 100 countries with cutting-edge sensor technologies.

Reputable makers use quality assurance programs to make sure that their products always work well and are reliable. Certifications from well-known standards groups give customers trust in the quality of a product and its ability to meet legal requirements. Customization services let you make solutions that fit the needs of a specific application. For example, you can change the size of the probe, use special materials, and make your own communication ports.

Cost-Effectiveness Analysis and Total Ownership Considerations

To make good buying choices, you should look at the total cost of ownership instead of just the purchase price. Long-term costs are affected by things like how accurate the sensors are, how reliable they are, how much upkeep they need, and how long they are supposed to work. Even though the initial cost is higher, a high-quality well level sensor with extended warranty coverage and superior accuracy ratings often provides better overall value through improved reliability, reduced maintenance needs, and longer service life.

Comprehensive technical support services lower the risks of adoption and make sure the system works at its best. When suppliers give help with application engineering, installation, and ongoing expert consultation, they add extra value that supports charging more. Both OEM and ODM services allow for private labeling, which meets the naming needs of customers while still meeting quality standards.

Strategic Partnership Development for Long-Term Success

To successfully buy sensors, you need to do more than just make one deal. You also need to build long-term partnerships. Suppliers with a global footprint and local support skills offer consistent service no matter where the project is located. A supplier's dedication to customer success is shown by their ability to respond quickly to technical questions and speed up delivery for urgent needs.

Framework contracts and bulk buying deals save money and make sure the supply chain works well. These deals are especially good for wholesalers and OEM customers who need to make sure their products are always available and the prices are fair. Flexible customization options let sellers change goods to meet the needs of specific markets while keeping production processes running smoothly.

Conclusion

Putting reliable level sensors into water pump systems is an important part of modern industrial processes. These high-tech tracking devices keep expensive equipment from breaking down and allow for advanced automation features that make operations run more smoothly. When choosing the right sensor technologies, you need to carefully think about the needs of the application, the surroundings, and your long-term reliable goals. Professional companies like GAMICOS offer complete solutions for a wide range of business needs by using cutting edge sensor technologies and offering a full range of support services. Investing in good level tracking systems pays off in a way that can be measured: lower upkeep costs, more reliable operations, and better automation of processes.

FAQ

What is the typical lifespan of a well level sensor?

Under normal conditions, a good underwater level sensor should work reliably for 5 to 10 years. The real lifespan relies on things like the type of liquid, the working temperature, the quality of the installation, and how often it is maintained. In good conditions, sensors that are well-built and have the right protection coatings can last longer than these time ranges.

How do I choose between different sensor technologies for my application?

During the decision process, things like measurement range, accuracy needs, placement limitations, and environmental conditions should be taken into account. Because they are accurate and reliable, pressure-based sensors work great in most industry settings. Ultrasonic sensors are good for non-contact tasks where the qualities of liquids might change how underwater sensors work. Talking to application experts can help you choose the best technology.

What maintenance is required for submersible level sensors?

As part of routine maintenance, the machine is cleaned to get rid of deposits, the wires and connections are visually checked, and the calibration is confirmed. When placed correctly, most devices don't need much upkeep. Advanced sensors that can diagnose problems give early warnings of possible problems, which lets you plan maintenance ahead of time.

Partner with GAMICOS for Superior Well Level Sensor Solutions

GAMICOS offers the best liquid level measurement options on the market, made especially for tough industrial uses. The innovative GLT530 underwater sensor line is part of our wide range of products. It has very small designs that are very accurate and reliable. We know how important it is to have solid pump safety systems because we've been serving customers in over 100 countries for over ten years. Our professional support team is here to help you with the selection, installation, and maintenance of products, making sure that they work perfectly for your purpose.

We are a reliable well level sensor maker, and to help you meet your project deadlines, we offer flexible OEM/ODM services and fast delivery. Get in touch with our engineering team at info@gamicos.com to talk about your level tracking needs and find out how our cutting-edge sensor technologies can protect your valuable pump investments and make your operations run more smoothly.

References

1. Industrial Automation Technology Review: Level Measurement Systems in Process Industries, Journal of Process Control Engineering, 2023.

2. Smith, J.R. and Williams, M.K., "Reliability Analysis of Submersible Pressure Sensors in Water Treatment Applications," Water Technology and Management Quarterly, Vol. 45, No. 3, 2023.

3. Chen, L. et al., "Comparative Study of Level Sensor Technologies for Industrial Pump Protection Systems," Sensors and Instrumentation International, 2022.

4. Rodriguez, P.A., "Cost-Benefit Analysis of Preventive Maintenance Using Smart Level Sensors," Industrial Maintenance and Plant Engineering, 2023.

5. International Standards Organization, "Guidelines for Selection and Installation of Liquid Level Sensors in Industrial Applications," ISO Technical Report 18754, 2022.

6. Thompson, D.H. and Anderson, K.L., "Wireless Monitoring Technologies for Remote Pump Station Management," Water Infrastructure Technology Review, Vol. 28, No. 4, 2023.

Halen

With over 12 years of experience in fluid sensing technology, Halen specializes in helping clients select and optimize oil level sensors for a wide range of industries—including automotive, marine, heavy machinery, and energy.

We're here to help — submit your request anytime!

Let us know how we can help solve your pressure level measurement challenge.

Recommended Blog

How to Choose a Well Level Sensor for Deep-Bore Applications?

How to Choose a Well Level Sensor for Deep-Bore Applications?

_1757930850792.jpg)