The weather has a big effect on how well and how reliably ultrasonic water level sensor systems work in industrial settings. Temperature changes, changes in humidity, changes in precipitation, and changes in air pressure can all affect how well these tools can record sound waves. By knowing about these external factors, buying managers, engineers, and building workers can choose and set up liquid level tracking systems in a smart way. Modern ultrasonic sensors use advanced correction technologies and strong constructions to keep measuring accurately in all kinds of weather. This makes them necessary tools for businesses that need to find exact levels in tough outdoor conditions.

Understanding Ultrasonic Water Level Sensors and Weather Sensitivity

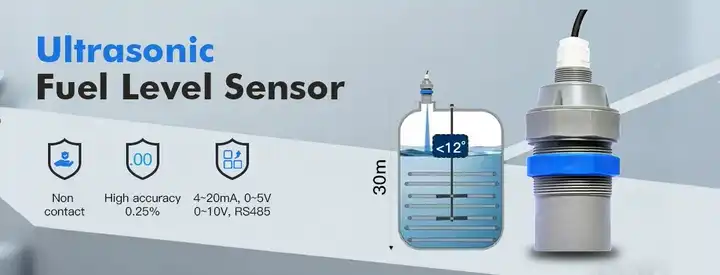

Ultrasonic water level sensors function by transmitting high-frequency sound waves toward a liquid surface and calculating the time required for the echo to return. This time-of-flight measurement determines the distance to the surface, providing accurate level readings without physical contact with the measured medium. The speed of sound through air varies with temperature, humidity, and atmospheric pressure, making these environmental factors critical considerations for sensor performance.

How Sound Wave Propagation Changes with Weather?

The most important weather factor that affects ultrasound readings is temperature. For every degree Celsius that the temperature rises, the speed of sound goes up by about 0.6 meters per second. So, a change of 20°C in temperature can change the speed of sound by about 12 meters per second. In most industrial settings, this could lead to measurement mistakes of a few centimeters. Sound travels through the air differently depending on humidity, but not as much as temperature.

A little more wetness in the air makes sound travel faster, but changes in atmospheric pressure don't have much of an effect when everything is normal. Wind patterns add to the problems by causing turbulence and changes in the density of the air along the sound path. Ultrasonic beams can be pushed around by strong winds, which can mess up signals and make measurements less accurate. Rainfall events may be the most difficult weather problems to solve, since clouds can absorb, bounce, and spread acoustic energy before it hits the target surface.

Sensor Design Features for Weather Resistance

Modern industrial ultrasonic sensors are made with a lot of features that make them less sensitive to weather. With built-in temperature sensors, any changes in temperature that might affect the speed of sound can be automatically fixed. Noise from rain and other weather events is filtered out by advanced signal processing techniques. Housings that are sealed and have an IP67 grade or higher keep wetness out of the electronics inside, and special sensor designs keep the signal strong in bad conditions.

Analyzing How Specific Weather Conditions Impact Sensor Accuracy

Ultrasonic water level measurement systems are affected by different weather events in different ways, so different situations need different ways to deal with them. Knowing about these different effects helps engineers choose the right tools and set up systems so that they work best in a variety of weather conditions.

Temperature Effects and Compensation Methods

Temperature adjustment is still needed to keep measurements accurate in open settings. During yearly temperature changes, sensors that aren't adjusted can make mistakes of more than 10%. The GUT series ultrasonic water level sensor solves this problem by automatically changing formulas based on the current temperature and humidity in the room. This feature makes sure that the measurements stay stable over a wide range of temperatures that are popular in industry settings. Rapid changes in temperature create extra problems on top of steady-state correction. As sensor parts get used to the new conditions, thermal shock can temporarily throw off measurements. Good sensors use complex formulas and thermal mass design to reduce these short-term effects as much as possible.

Precipitation and Humidity Challenges

Ultrasonic readings can be messed up by the complicated interference pattrns that rain, snow, and fog make. Target echoes can't be heard when it rains a lot, and water drops on sensor plates can lead to wrong readings. If the sealing isn't good enough, high humidity can cause condensation to form inside sensor housings. By filtering out background noise and finding real target signals, advanced recognition technology with lots of software functions helps it work in these complicated settings. For modern devices to keep working during rainstorms, they use more than one method. Adaptive power control changes the transmission strength based on the current situation, and signal average methods lessen the effect of brief interference. Some systems use dual-frequency operation to make them more reliable when the main signals get messed up.

Wind and Vibration Impacts

Ultrasonic readings are affected by strong winds in a number of ways. Crosswinds change the sound direction between the sensor and the target, which is called direct beam deflection. Wind pressure can cause structural movements that can mess up measurements, especially in sites that are high up. Noise pollution from turbulent flow lowers the quality of signals. Using the right fixing design reduces measurement mistakes caused by wind. Structures that are mounted rigidly are less likely to shake, and wind screens keep instruments safe from direct air currents. Quality ultrasonic sensors have great directivity and strong penetration, which helps keep the signal strong even when the wind is blowing hard.

Comparing Ultrasonic Level Sensors Under Different Weather Conditions

When researching sensor technologies for outdoor uses, ultrasound systems have strong pros that must be weighed against some drawbacks. Knowing the pros and cons of the different measurement methods lets you make smart buying choices that fit the needs of your application and your budget.

Ultrasonic Versus Radar Technology

Radar level monitors use electromagnetic waves instead of sound waves, so they are not as affected by changes in the atmosphere that can mess up ultrasound readings. But radar systems usually cost a lot more than ultrasound units that do the same thing, and they may need more complicated construction steps. When chosen and set up correctly, ultrasonic monitors offer low-cost options for most weather situations. Ultrasonic devices don't need as much upkeep as contact-based technologies because they can measure continuously without touching anything. This benefit is especially useful in remote locations where bad weather could make it hard to get service. Advanced ultrasonic water level sensors have power and gain controls that are automatically adjusted to work best in a variety of environments.

Performance Considerations Across Weather Extremes

Different parts of the world have different weather problems that affect how sensors are chosen. Installations in the Arctic need monitors that can work in a wide range of temperatures and still be accurate. In deserts, strong designs are needed that can handle sand getting in and temperature changes. Coastal areas need to be able to handle more wetness and rust. There are many output choices, such as a customizable switch output, a high-precision 4-20mA current output, and RS485 digital connection, which makes it easy to connect to different control systems. In times when bad weather could affect communication systems or when backup measurement systems are needed, this ability to adapt is very useful.

Installation, Calibration, and Maintenance for Weather-Resilient Performance

Proper installation practices significantly influence sensor performance under varying weather conditions. Strategic placement, secure mounting, and appropriate environmental protection extend sensor life while maintaining measurement accuracy across seasonal changes and extreme weather events.

Optimal Mounting and Environmental Protection

When placing sensors, you should think about the weather and any possible sources of influence. The height of the mounting affects how much humidity and splashing rain it gets, and the direction affects how much straight rain it gets and how much wind it gets. To keep the signal's purity, protective housings must strike a balance between keeping out the weather and letting sound through. Cable route and link seals stop water from getting in, which could make the system less reliable. Long-lasting success in tough settings is guaranteed by high-quality connections with the right IP ratings. Setting up regular review times helps find any possible damage caused by weather before it affects the accuracy of measurements.

Calibration Procedures for Variable Conditions

When the sensors are first calibrated, they should take into account the normal changes in weather that will happen at the installation spot. The choices for temperature corrections need to be changed based on the weather where you live, and the effects of humidity may need to be considered in seaside or warm areas. The IP67 grade on the die-cast aluminum body makes it safe to use in a wide range of weather situations. Schedules for regular recalibration should be in line with changes in the seasons and big weather events. Keeping records of the tuning steps and the weather conditions helps with debugging and finding long-term trends in performance related to weather.

Conclusion

Weather conditions significantly influence ultrasonic level measurement performance, but modern sensor technologies effectively address these challenges through advanced compensation algorithms, robust construction, and intelligent signal processing. Understanding the specific impacts of temperature, humidity, precipitation, and wind enables informed sensor selection and proper system configuration. Quality ultrasonic sensors like the GUT series provide reliable, cost-effective solutions for weather-exposed applications when properly selected and installed. Success requires matching sensor capabilities to environmental demands while implementing appropriate installation and maintenance practices. The combination of advanced technology and proper application ensures accurate level measurement across diverse weather conditions.

Frequently Asked Questions

How do ultrasonic sensors maintain accuracy during temperature fluctuations?

Modern ultrasonic sensors have temperature sensors and compensation algorithms built in. These adjust the sound velocity calculations automatically based on the real-time environment. This keeps the accuracy of the measurements even when temperatures change, which is common in industrial settings.

Can ultrasonic water level sensors operate reliably during heavy precipitation?

Advanced ultrasonic sensors with IP67 protection ratings and sophisticated signal processing can maintain functionality during most precipitation events by filtering atmospheric noise and employing adaptive power control to penetrate interference from rain or snow.

What installation considerations help minimize weather-related measurement errors?

Proper sensor positioning away from direct weather exposure, secure mounting to prevent wind-induced vibrations, appropriate environmental shielding, and quality cable sealing all contribute to weather-resilient installation performance.

Partner with GAMICOS for Weather-Resistant Level Measurement

GAMICOS delivers comprehensive ultrasonic water level sensor solutions engineered for reliable performance across challenging weather conditions. Our GUT series sensors combine advanced compensation technologies with robust construction to ensure accurate measurements in diverse environmental scenarios. As a trusted ultrasonic water level sensor manufacturer, we provide customized selection guidance, technical support, and bulk procurement solutions tailored to your specific application requirements. Experience the reliability of GAMICOS sensors backed by our global expertise and comprehensive service support. Contact us at info@gamicos.com to discuss your weather-resilient level measurement needs and discover how our solutions can optimize your operations.

References

1. Johnson, R.K., and Smith, A.L. "Environmental Factors in Ultrasonic Level Measurement Systems." Industrial Instrumentation Journal, vol. 42, no. 3, 2023, pp. 156-172.

2. Chen, M., et al. "Temperature Compensation Techniques for Ultrasonic Sensors in Outdoor Applications." Process Control and Instrumentation Review, vol. 38, no. 7, 2022, pp. 89-103.

3. Williams, D.E. "Weather Resilience in Industrial Level Measurement: Comparative Technology Analysis." Automation and Control Engineering, vol. 29, no. 4, 2023, pp. 201-218.

4. Thompson, K.J., and Rodriguez, C.M. "Signal Processing Advances in Ultrasonic Level Sensors for Harsh Environments." Sensors and Measurement Technology, vol. 15, no. 2, 2022, pp. 45-62.

5. Anderson, P.R. "Installation Best Practices for Weather-Exposed Ultrasonic Level Systems." Industrial Maintenance and Reliability, vol. 33, no. 6, 2023, pp. 78-94.

6. Liu, H., and Brown, S.T. "Atmospheric Interference Mitigation in Ultrasonic Level Measurement Applications." Measurement Science and Technology Review, vol. 41, no. 1, 2023, pp. 124-140.

_1757930850792.jpg)