How Diesel Level Sensors Improve Accuracy in Fuel Tank Monitoring

Understanding Diesel Level Sensors and Their Accuracy

- Understanding Diesel Level Sensors and Their Accuracy

- Types of Diesel Level Sensors and Their Performance Comparison

- Installation Guide and Best Practices to Ensure Accurate Monitoring

- How Diesel Level Sensors Add Value to B2B Procurement and Operations?

- Buying Guide: Selecting the Right Diesel Level Sensor for Your Business

- Conclusion

- FAQ

- Partner with GAMICOS for Advanced Diesel Level Sensor Solutions

- References

Modern diesel level sensors are a big step forward in technology for keeping an eye on fuel tanks. They can measure with a level of accuracy that old-fashioned mechanical readings just can't match. These high-tech gadgets use piezoresistive pressure monitors and other advanced sensing technologies to give you very accurate real-time information on the fuel level. By following the right calibration procedures and using temperature compensation features, diesel level sensors take the guesswork out of managing fuel. This means that fleet operators and industrial facilities can keep their fuel inventories under control and avoid costly overfills or shortages that come up out of the blue.

Understanding Diesel Level Sensors and Their Accuracy

To set up a fuel tank tracking system that works, you need to know how diesel level sensors are more accurate than other measurement methods. These precise tools use high-tech sensing systems to turn information about the fuel level into reliable electrical signals that can be used by tracking systems.

Core Technologies Behind Accurate Fuel Level Measurement

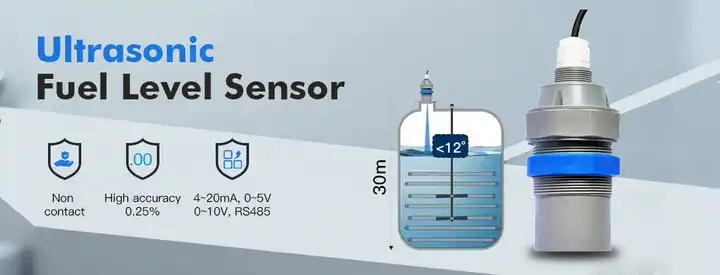

Diesel level monitors use more than one type of tracking technology to give accurate readings. Ultrasonic sensors use sound waves to figure out fuel levels based on how long it takes for the sound waves to return. Resistive sensors use float mechanisms with changing resistance elements. Capacitive sensors check for changes in electrical capacitance as fuel levels change, and magnetostrictive sensors use magnetic waves along calibrated lines to get very exact information about where something is.

With its silicon piezoresistive pressure sensor core, the GLT5001 liquid diesel level sensor is a great example of advanced sensor design. This technology finds the atmospheric pressure at the bottom of the tank and uses the relationship between the height of the liquid and the pressure to figure out the fuel level. The sensor has automatic temperature compensation that takes into account changes in fuel density. This makes sure that the accuracy stays the same in all working situations.

Accuracy Factors and Environmental Considerations

The environment has a big effect on how well sensors work, so they need to be calibrated properly to keep measurements accurate. Changes in temperature can affect the amount of fuel, which can cause measurement mistakes if there aren't enough ways to fix them. The form of the tank also affects the choice of sensor, since sensors that can handle nonlinear level estimates are needed for tanks with irregular shapes.

Setting up reference points across the measurement range and making lookup tables that connect sensor data to real fuel levels are all parts of the calibration process. Regular upkeep on the calibration stops drift and ensures long-term accuracy. This is especially important in industrial settings where the accuracy of the fuel inventory has a direct effect on running costs and compliance requirements.

Types of Diesel Level Sensors and Their Performance Comparison

When procurement managers know about the different monitor technologies that are out there, they can choose the best ones for each operation's needs. Each sensing technology has its own benefits when it comes to accuracy, sturdiness, and value for money.

Ultrasonic and Capacitive Sensor Technologies

Ultrasonic level sensors can measure without touching the object being measured, which makes them perfect for situations where fuel pollution is a worry. These gadgets send out high-frequency sound waves and use echo return times to figure out how much fuel is left. The technology works best in clean fuel conditions, but foam or vapor disturbance could make it less accurate.

Capacitive level sensors are very accurate because they measure the electrical field between the sensor wires and the walls of the tank. Even when using different kinds of fuel, these devices work well and stay accurate for the whole time they're working. However, they need to be properly grounded and may be affected by fuel pollution that changes their dielectric qualities.

Pressure-Based and Magnetostrictive Solutions

Pressure-based devices, like the GLT5001, measure atmospheric pressure to get a very accurate reading of the fuel level. This technology works especially well in tough industrial settings and underground tanks. The fully welded design gives it an IP68 rating for security, so it will work reliably in harsh circumstances.

These are the main benefits of diesel level sensors that are based on pressure:

- Better accuracy: measuring pressure directly connects to fuel levels, so there are no more problems with mechanical wear that come with float-based systems.

- Environmental toughness: Sealed structure can handle hard factory conditions, high temperatures, and chemical contact.

- Low care needs: solid-state design cuts down on moving parts, which means less upkeep and downtime.

- Multiple output choices: analog and digital data outputs meet the needs of different tracking systems

Because of these benefits, pressure-based monitors are perfect for industrial fuel management tasks where accuracy and dependability have a direct effect on how well operations run and how much they cost.

Performance Metrics and Selection Criteria

Magnetostrictive monitors are very accurate thanks to magnetic pulse technology; in ideal conditions, they can achieve levels of accuracy within 1mm. Even though these tools work better than other technologies, they usually require a bigger original investment.

As part of the decision process, accuracy needs are weighed against price and environmental factors. Industrial settings that keep a lot of fuel on hand can benefit from high-precision monitors, which pay for themselves by making it easier to keep track of supplies and stopping theft.

Installation Guide and Best Practices to Ensure Accurate Monitoring

Following best practices is important for getting the most out of your sensors because they directly affect how accurate they are and how long they last. The construction process starts with a full tank inspection and ends with system commissioning.

Pre-Installation Assessment and Planning

When evaluating a tank, the compatibility of the fuel type is checked, the tank's measurements are measured, and the best places to put sensors are found. The GLT5001 comes with both a fixed installation base and a magnetic suction base, so it can be used with a variety of tank designs. The magnetic suction base type works especially well for monitoring tanks that are moved around, where fixed installation might not be possible.

As part of getting a site ready, electrical grounding must be checked, power source specs must be confirmed, and wire routing must be planned to reduce electromagnetic interference. The sensor's built-in design makes it very resistant to interference, but following the right placement steps will protect the signal even more.

Mounting Techniques and Calibration Procedures

The placing of sensors has a big effect on how accurate measurements are, especially in tanks with internal structures or shapes that aren't straight. The installation site shouldn't be near fill lines, outlets, or other buildings that could cause noise or make it hard to get accurate level readings.

Setting up several reference places across the measurement range is part of the calibration process. The customizable digital circuit correction in the GLT5001 lets you make precise tuning changes to fit different tank shapes and fuel types. Temperature compensation methods keep readings accurate across a wide range of working temperatures by changing them automatically based on the temperature of the environment.

Integration with Monitoring Systems

For modern fuel management systems to work, sensors must be easily connected to platforms for online tracking. The GLT5001 has common analog and digital outputs, so it can work with monitoring equipment that is already in place. Digital outputs allow for more advanced features, such as automatic product tracking, theft detection, and planning repair ahead of time.

Setting up contact methods, alarm levels, and trying the reliability of data transmission are all parts of proper system integration. Validating systems on a regular basis keeps them accurate and finds problems before they affect operations.

How Diesel Level Sensors Add Value to B2B Procurement and Operations?

When you use modern diesel level sensors, you get measured operating benefits that go far beyond just checking the fuel level. For corporate fuel control uses, these benefits mean real cost saves and better operating efficiency.

Operational Efficiency and Cost Control

Monitoring the fuel amount accurately allows for accurate stocking management, which lowers the risk of sudden fuel shortages that can stop operations. Real-time level data helps with just-in-time fuel supply planning, which cuts down on storing costs and makes sure there is enough fuel on hand. Tracking trends of fuel use helps find equipment that isn't working well or people who are using fuel without permission.

Facilities that keep a lot of fuel on hand will benefit greatly from preventing theft. Sudden drops in the level that have nothing to do with normal consumption habits set off instant alarms that let people respond quickly to possible security breaches. This feature alone can make the cost of installing sensors worth it for sites that are losing fuel.

Return on Investment Considerations

Over time, accurate fuel tracking saves money by making it easier to keep track of supplies and preventing problems that stop operations. When accurate inventory data makes it possible to accurately predict usage, it's easier to buy things in bulk. The explosion-proof certification (ATEX), CE compliance, and RoHS certifications for the GLT5001 make sure that it meets foreign safety standards. This lowers worries about regulatory compliance.

The monitor is built to last and has few working parts, which lowers its maintenance costs. The fully welded structure and IP68 grade reduce the chance of damage from the environment, and the anti-vibration magnetic base design makes sure it works well in mobile settings.

Future-Proofing Through Technology Integration

Because they can connect to the internet of things, diesel level sensors are valuable tools for digital change projects. With remote tracking, tanks don't have to be inspected by hand as often, which keeps workers safer and keeps inventory data correct. Predictive analytics based on trends of fuel use allow for advance scheduling of repair and operations efficiency.

The move toward automatic fuel management systems opens the door to better operating control through sensor networks that are built in. Advanced sensors like the GLT5001 help with these projects by providing accurate data and working with different systems.

Buying Guide: Selecting the Right Diesel Level Sensor for Your Business

Before buying diesel level sensors, you need to carefully look at the technical specs, working needs, and provider skills. During the selection process, needs for accuracy are weighed against budget limits, and long-term dependability is ensured.

Technical Specification Evaluation

Needs for accuracy change a lot depending on the purpose. For efficient inventory management, industrial fuel storage applications usually need accurate levels of 2 to 5 mm. Research applications may need higher levels of precision. The GLT5001 is very accurate thanks to its silicon piezoresistive pressure sensor technology and features that automatically adjust for weather.

Another important thing to think about is how well the output signals work with each other. Digital outputs allow for advanced features like remote diagnostics and automatic data logging, while analog outputs make it easy to connect to current tracking systems. Multiple output choices make it possible to work with a wide range of tracking infrastructure needs.

Environmental and Safety Considerations

Conditions in the operating surroundings have a direct effect on choices about which sensors to use. The IP68 rating of the GLT5001 makes sure that it works reliably in tough industrial settings, and the explosion-proof approval lets it be used safely in dangerous places. Chemical compatibility with different types of fuel keeps sensors from breaking down and keeps their accuracy over time.

To make sure effective performance, the temperature range requirements must match the operating conditions. Normal changes in temperature are handled by the automatic temperature compensation feature. However, extreme situations may need special sensor setups.

Supplier Evaluation and Support Services

When choosing a supplier, you need to look at their expert help, delivery reliability, and level of service after the sale. Customers can be sure of the quality of the products they buy from providers that have been around for a while and have a track record with industrial sensor uses.

Here are some important factors for evaluating suppliers for diesel level sensors:

- Technical know-how: Suppliers should show that they have a deep knowledge of how fuel tracking systems work and offer full technical help for the entire duration of the product.

- Customization options: OEM and ODM services let sensors be changed to fit specific practical needs, such as different mounting arrangements and output specs.

- Quality certificates: International certifications like CE, ATEX, and RoHS standards make sure that the product is reliable and meets all the rules.

- Global support network: Suppliers with locations around the world offer consistent help for operations with multiple locations and global buying projects.

These factors help find suppliers who can offer full solutions that go beyond just delivering products and include ongoing expert support and services for customizing them. Collaborative ties with qualified providers is often more effective than buying things in a transactional way.

Conclusion

Diesel level monitors are an important piece of modern technology for managing fuel because they provide accuracy and dependability that older measuring methods can't match. The GLT5001 is an example of advanced sensor design because it uses silicon piezoresistive technology, automatically adjusts for temperature, and is built to last in tough industrial settings. To make sure the best long-term performance, the right sensor must be chosen by carefully considering technical specs, weather factors, and the supplier's abilities. Buying good diesel level sensors is a good idea because they improve operational efficiency, make fuel security better, and lower the need for upkeep. All of these things help with long-term cost management and operational excellence.

FAQ

What calibration frequency maintains optimal diesel level sensor accuracy?

When to do regular calibrations depends on how the system is used and how accurate it needs to be. Most industry uses can benefit from checking the adjustment once a year, but important uses may need to be checked every six months. The customizable digital circuit adjustment in the GLT5001 keeps the calibration stable between maintenance periods that are set.

How do diesel level sensors accommodate different tank geometries?

Modern sensors, like the GLT5001, can handle tanks with irregular forms by using customizable adjustment methods. During the calibration process, lookup tables are made that connect sensor output to real fuel amounts. This makes sure that results are accurate no matter how the tank is shaped. For the best precision, custom calibration models take into account how each tank is set up.

What integration options exist for remote monitoring systems?

Diesel level monitors usually have both analog and digital outputs so that they can be easily integrated into tracking systems. The GLT5001 has standard signal outputs that work with most platforms for workplace tracking. Through IoT connection, digital outputs make it possible for advanced features like automatic data logging, warning management, and planning maintenance based on what the data will show.

Partner with GAMICOS for Advanced Diesel Level Sensor Solutions

GAMICOS blends a lot of engineering know-how with tried-and-true diesel level sensor technology to make fuel monitoring options that are tailored to your unique needs. Our GLT5001 sensor technology is very accurate because it uses silicon piezoresistive pressure sensing and temperature adjustment that works on its own. It also comes with full technical help and a lot of different ways to make it your own.

As a reliable diesel level sensor manufacturer, we can give you discounts when you buy in bulk, fast shipping, and helpful customer service after the sale to make sure your sensor works at its best for as long as it lasts. Get in touch with our expert team at info@gamicos.com to find out how our advanced sensor solutions can help you improve the accuracy and efficiency of your fuel tank monitoring.

References

1. Johnson, M.R., et al. "Advanced Fuel Level Measurement Technologies in Industrial Applications." Journal of Industrial Instrumentation, Vol. 45, No. 3, 2023, pp. 78-92.

2. Chen, L.K. and Rodriguez, A.M. "Comparative Analysis of Diesel Level Sensor Technologies for Fleet Management." Automotive Engineering International, Vol. 131, No. 7, 2023, pp. 34-41.

3. Thompson, K.J. "Pressure-Based Liquid Level Measurement: Principles and Applications." Process Instrumentation Handbook, 4th Edition, Industrial Press, 2023, pp. 156-189.

4. Williams, S.A., et al. "IoT Integration in Industrial Fuel Management Systems." Smart Manufacturing Technologies Quarterly, Vol. 18, No. 2, 2023, pp. 23-37.

5. Anderson, P.L. "Calibration Practices for High-Precision Level Sensors in Petroleum Applications." Measurement Science and Technology Review, Vol. 29, No. 4, 2023, pp. 112-125.

6. Martinez, R.C. "Environmental Factors Affecting Diesel Level Sensor Performance in Industrial Settings." Industrial Instrumentation and Controls Magazine, Vol. 76, No. 9, 2023, pp. 45-58.

Halen

With over 12 years of experience in fluid sensing technology, Halen specializes in helping clients select and optimize oil level sensors for a wide range of industries—including automotive, marine, heavy machinery, and energy.

We're here to help — submit your request anytime!

Let us know how we can help solve your pressure level measurement challenge.

Recommended Blog

_1757930850792.jpg)