Emerging Water Level Technologies in Manufacturing

Introduction

- Introduction

- Emerging Paradigms in Industrial Water Level Sensor Technology

- Top 5 Industrial Water Level Sensor Technology Trends Transforming Manufacturing

- Industrial Water Level Sensor Technology Comparison and Selection Guide

- Practical Guide: Industrial Water Level Sensor Installation, Maintenance, and Calibration

- Company Introduction & Solutions for Industrial Water Level Sensing

- Conclusion

- FAQ

- Call to Action: Partner with GAMICOS for Advanced Water Level Sensing Solutions

- References

Throughout many industrial processes, accurate water level monitoring is essential to manufacturing quality. With previously unheard-of precision and dependability, the newest industrial water level sensor technologies are completely changing the way manufacturers approach fluid measurement. These cutting-edge devices revolutionize conventional industrial processes by combining intelligent connection, improved durability, and predictive capabilities. Modern water level sensor technologies minimize downtime risks and operating expenses while enabling real-time process optimization via IoT integration and AI-powered analytics.

Introduction

Water level sensing has a direct influence on accuracy, productivity, and safety in a variety of industrial applications, making it an essential component of manufacturing process optimization. Accurate liquid level monitoring is the foundation of dependable operations, from pharmaceutical institutions maintaining clean water systems to chemical processing plants handling corrosive liquids. Industrial water level sensors, for example, must be able to survive harsh circumstances while providing reliable, real-time data to automated control systems in today's production operations.

Due to Industry 4.0 ambitions and the increasing need for remote monitoring capabilities, the development of water level measuring technology has increased significantly in recent years. Sophisticated digital systems that provide improved precision, longer operating life, and seamless interaction with plant-wide control networks are replacing conventional mechanical float switches and simple pressure sensors. Manufacturers are able to increase overall equipment performance, decrease waste, and achieve stricter process control thanks to these technical advancements.

To fulfill the rigorous needs of contemporary industrial applications, top sensor manufacturers and technology developers worldwide are making significant investments in research and development. Innovative systems that integrate several sensor technologies, wireless connection, and sophisticated signal processing capabilities are being introduced by companies that specialize in level measuring solutions. Manufacturers now have more chances to streamline their processes while adhering to stricter safety and environmental standards because to this convergence of technologies.

Emerging Paradigms in Industrial Water Level Sensor Technology

Although they have been useful in production, traditional sensing technologies like float switches, simple pressure sensors, and ultrasonic sensors have serious drawbacks in terms of accuracy, robustness, and environmental adaptation. Despite being easy to use and reasonably priced, float switches are not ideal for applications requiring viscous or polluted liquids due to mechanical wear. While early ultrasonic sensors have difficulties in settings containing foam, vapor, or very high or low temperatures, basic pressure sensors often suffer from temperature fluctuations and need to be recalibrated.

Sensor capabilities are undergoing a fundamental transformation due to industry drivers including IoT integration, Industry 4.0 connection, improved materials, downsizing, artificial intelligence, and data analytics. Sensors may send data straight to cloud-based systems thanks to the incorporation of wireless communication protocols, enabling centralized monitoring and management across several locations. Sensor components that can tolerate high temperatures, resist corrosion, and retain precision for long periods of time without maintenance have been made possible by advances in materials science.

Wireless networks and smart sensors with self-calibration capabilities provide real-time insights that greatly increase industrial uptime and cost effectiveness. By automatically modifying their settings in response to changing environmental circumstances, these smart devices minimize calibration downtime and the need for human involvement. Predictive maintenance techniques that stop equipment breakdowns before they happen are made possible by machine learning algorithms integrated into sensor systems that can spot trends in measurement data.

Key Technological Milestones in Sensor Evolution

Modern smart sensor systems are the result of decades of constant improvement, starting with mechanical float switches. More precise measurement and noise reduction were made possible with the introduction of digital signal processing in the 1990s. Reliability and miniaturization were made possible by the early 2000s development of MEMS technology. Recent developments in edge computing and wireless communication have produced sensors that can operate independently and make intelligent decisions.

Top 5 Industrial Water Level Sensor Technology Trends Transforming Manufacturing

Enhanced Accuracy Through Multi-Modal Sensing

A novel technique called multi-modal sensing combines information from pressure, radar, and ultrasonic sensors—including industrial water level sensors—to provide previously unheard-of measurement precision. This technique is essential for mission-critical applications where measurement mistakes may cause serious financial losses or safety risks because it balances the advantages of various sensing principles while accounting for individual constraints. By combining many sensor inputs, a complete image of liquid behavior is produced, making it possible to identify foam layers, density changes, and interface levels between various liquids.

Robust Design for Extreme Environments

Extremely demanding manufacturing settings in industries like mining, chemicals, and oil & gas need outstanding sensor endurance. In order to operate in dangerous environments with explosive atmospheres, corrosive chemicals, and severe temperatures ranging from -40°C to +200°C, modern sensor designs include cutting-edge materials and protective technology. These sturdy sensors satisfy strict certification criteria, such as ATEX, IECEx, and FM clearances for hazardous area installations, while maintaining measurement accuracy.

Wireless and Remote Monitoring Capabilities

Many installation hassles have been removed by wireless sensor technology, which also makes advanced cloud-based data analytics possible. These systems provide flexibility for short-term monitoring applications, save wiring costs, and make retrofitting existing facilities easier. Remote monitoring features facilitate dispersed production processes and enable quick reaction to changing circumstances by giving operators access to real-time data from any location.

Predictive Maintenance Integration

A paradigm change from reactive to proactive maintenance approaches is represented by sensors with embedded predictive maintenance capabilities. Before measurement accuracy is jeopardized, these intelligent systems continually check their own performance metrics, spotting early indicators of drift, fouling, or component deterioration. Predictive algorithms can estimate maintenance needs and improve service schedules by examining past performance data and environmental factors.

Customizable and Modular Solutions

The increasing need for modular, configurable sensors is a reflection of the various needs of bulk procurement agreements and OEM manufacturers. Sensor kinds, transmission protocols, housing materials, and cable specifications are just a few of the many configuration possibilities available on contemporary sensor systems. Manufacturers can precisely define the characteristics they want thanks to this flexibility, which also keeps costs down for high-volume applications.

Industrial Water Level Sensor Technology Comparison and Selection Guide

A thorough assessment of performance traits, environmental compatibility, durability requirements, and total cost of ownership is necessary when choosing the best sensor technology. Understanding the merits of various sensor types in certain applications enables procurement teams to make well-informed selections that fit their operational needs and financial restrictions.

Performance Comparison of Major Sensor Types

For the majority of liquids, ultrasonic sensors provide non-contact measurement with acceptable accuracy; however, temperature gradients, mist, or foam may impair their effectiveness. Although radar sensors usually demand a larger initial expenditure, they work better in difficult situations like foam or mist. Although hydrostatic pressure sensors are very accurate and dependable, they can need further adjustment for changes in density.

Long-term sensor performance and economical maintenance are greatly influenced by material concerns. For the majority of industrial applications, stainless steel structure offers exceptional corrosion resistance; nevertheless, very aggressive chemicals may need specific coatings and materials. Choosing the right sealing technology guarantees dependable performance in damp or submerged situations while preserving measurement accuracy over time.

Sensor technology, accuracy requirements, and customisation demands all affect market price. For simple applications, standard ultrasonic sensors are usually the most affordable option; however, multi-modal systems like high-precision radar command premium prices that are justified by their higher performance in demanding situations. Expected lead times often vary from stock goods that may be delivered in a matter of days to custom-engineered solutions that take weeks to manufacture and test.

Practical Guide: Industrial Water Level Sensor Installation, Maintenance, and Calibration

Proper installation procedures that take into account mounting position, climatic conditions, and system integration needs are the first step towards achieving optimum sensor performance. The placement of industrial water level sensors has a direct impact on measurement accuracy, and knowing the features of each technology helps guarantee dependable performance for the duration of the sensor's useful life.

Installation Best Practices

Liquid characteristics, vessel shape, and possible interference sources must all be taken into account while placing a sensor. In order to prevent misleading readings, ultrasonic sensors must be mounted away from filling streams and agitators and must have a clear line of sight to the liquid surface. For pressure sensors to provide precise atmospheric adjustment, mounting depth and venting configurations must be carefully considered.

Protection from mechanical damage, heat cycling, and electromagnetic interference are among the environmental factors to be taken into account during installation. Routing cables should reduce their exposure to hot surfaces, moving machines, and sharp edges. In electrically loud industrial settings, proper shielding and grounding are essential for preserving measurement stability and signal integrity.

Maintenance and Calibration Protocols

In addition to extending operational life, routine cleaning and inspection procedures guard against measurement drift, which might jeopardize process control. Physical damage, corrosion, or contamination that can impair sensor function should be detected by visual examination. Cleaning protocols need to be customized for individual sensor types and environmental circumstances, paying close attention to preserving the integrity of protective coatings and sensing surfaces.

Sensor technologies differ greatly in their calibration techniques, which should be carried out in accordance with process specifications and manufacturer recommendations. The majority of contemporary sensors include self-diagnostic features that assist in determining when recalibration is required. Calibration regimens that are established according to previous performance data and process criticality guarantee measurement accuracy while reducing needless downtime.

Company Introduction & Solutions for Industrial Water Level Sensing

As a recognized leader in liquid level and pressure measuring systems, GAMICOS combines a wealth of research and development resources with a track record of superior production. Our all-encompassing strategy combines cutting-edge sensor technology with adaptable solutions made to satisfy the exacting specifications of industrial applications across the world. In the industrial sensor sector, GAMICOS has built a reputation for innovation, quality, and dependability thanks to its products, which are sold to more than 100 countries and serve thousands of clients each year.

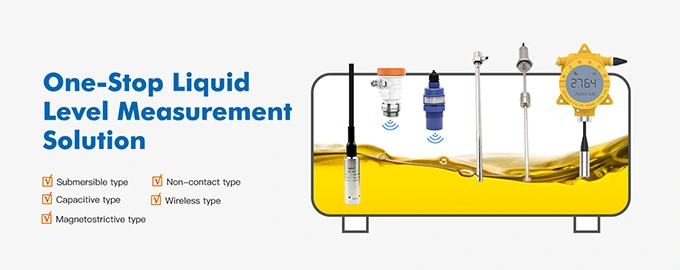

Pressure sensors, liquid level sensors, ultrasonic level meters, radar level meters, and wireless monitoring systems that support Lora, GPRS, NB-IoT, and 4G communication protocols are just a few of the sensing technologies that are included in our product line. Our dedication to technical quality is shown by the GLT500 submersible water level sensor, which has a high-reliability silicon piezoresistive pressure sensor core with programmable digital circuit rectification and automated temperature adjustment.

Advanced Product Capabilities

The GLT500's all-stainless steel design, completely waterproof sealed circuit technology, and several pressure range choices showcase GAMICOS' technical prowess. In addition to delivering typical industrial signal outputs, this adaptable sensor may be customized with cables that are resistant to wear, grease, and acid-alkali for specific uses. Even in demanding industrial settings, a prolonged service life is guaranteed by the anti-clogging liquid entry design with pressure vent holes.

From initial product selection and installation to continuing maintenance and calibration support, our technical support staff offers thorough help throughout the whole product lifespan. Our dedication to establishing enduring relationships that promote operational success for our industrial customers is shown by our flexible delivery schedules and warranty choices. Complete specification, packaging, and documentation customisation to satisfy particular client needs is made possible by expert OEM and ODM services.

Conclusion

Thanks to developments in artificial intelligence, wireless networking, and materials science, industrial water level sensor technology is still undergoing rapid change. Manufacturers that adopt these technology trends set themselves up for increased process control capabilities, lower maintenance costs, and better operational efficiency. Predictive maintenance capabilities combined with smart industrial water level sensors mark a fundamental change toward proactive asset management that reduces unscheduled downtime. Intelligent water level monitoring devices are becoming more and more important for preserving competitive advantage in contemporary production settings as Industry 4.0 efforts spread around the world.

FAQ

Q1: How do different sensor technologies measure water levels?

A: Ultrasonic sensors use the speed of sound to calculate distance by measuring the time it takes for sound waves to reach the liquid's surface and return. Unlike ultrasonic technology, radar sensors employ electromagnetic waves that are less impacted by temperature, moisture, or foam. The pressure exerted by the liquid column is measured by hydrostatic pressure sensors. The formula P = ρ × g × H + Po, where ρ stands for liquid density, g for gravitational acceleration, H for liquid height, and Po for atmospheric pressure, shows that the pressure is directly proportional to liquid height.

Q2: What factors affect sensor accuracy in industrial applications?

A: Temperature fluctuations may have a substantial effect on measurement accuracy, especially for ultrasonic sensors where temperature affects sound speed. Depending on the measuring technique, liquid characteristics including density, viscosity, and surface tension have varying effects on sensor performance. When choosing and installing sensors, environmental concerns including vibration, electromagnetic interference, and air conditions must be taken into account.

Q3: What maintenance practices ensure optimal sensor performance?

A: Contamination accumulation that might compromise accuracy is avoided by routinely cleaning sensor surfaces. Measurement drift may be found before it affects process control by periodic calibration verification using established reference values. Potential damage from mechanical stress, chemical exposure, or temperature cycling that can jeopardize signal integrity is found via cable inspection.

Call to Action: Partner with GAMICOS for Advanced Water Level Sensing Solutions

GAMICOS delivers cutting-edge industrial water level sensor technology designed to optimize manufacturing precision and operational efficiency. Our engineering team works closely with procurement managers and project engineers to develop customized solutions that address specific application challenges while meeting budget requirements and delivery schedules. Contact our technical specialists at info@gamicos.com to discuss your water level measurement requirements and explore how our industrial water level sensor manufacturer can support your operational objectives.

References

1. Johnson, M.R. and Chen, L., "Advanced Sensor Technologies in Industrial Automation: Trends and Applications," Journal of Manufacturing Technology, Vol. 45, No. 3, 2023.

2. Smith, P.A., Thompson, K.J., and Williams, R.M., "IoT Integration in Industrial Process Control: A Comprehensive Review," International Conference on Industrial Automation Proceedings, 2023.

3. Rodriguez, C.E., "Predictive Maintenance Strategies for Industrial Sensor Networks," Industrial Engineering and Management Review, Vol. 18, No. 2, 2023.

4. Lee, S.H. and Parker, D.G., "Multi-Modal Sensing Approaches for Enhanced Measurement Accuracy in Manufacturing Applications," Sensors and Actuators in Industry, Vol. 12, No. 4, 2022.

5. Anderson, B.L., "Wireless Sensor Networks in Industrial Environments: Design Considerations and Performance Analysis," IEEE Transactions on Industrial Informatics, Vol. 19, No. 1, 2023.

6. Kumar, A., Singh, R., and Brown, T.M., "Material Innovations in Industrial Sensor Design for Extreme Environment Applications," Advanced Materials in Manufacturing, Vol. 8, No. 6, 2023.

Peter

Peter, Senior Sensor Technology Consultant, has 15-year industrial sensor R&D experience. He specializes in the end-to-end development of high-accuracy pressure and level sensors and he firmly believe, precision isn’t just a spec—it’s a promise.

We're here to help — submit your request anytime!

Let us know how we can help solve your pressure level measurement challenge.

Recommended Blog

Submersible Level Sensors: Accuracy Meets Corrosion Resistance

Pharmaceutical Tank Level Measurement: Why Choose Radar Technology

How to Choose the Right Liquid Level Sensor for Your Tank?

How to Choose the Right Liquid Level Sensor for Your Tank?

How to Choose the Right Liquid Level Sensor for Your Tank?

_1757930850792.jpg)