Diesel Level Sensor Used in Oil & Energy Facilities

Understanding Diesel Level Sensors in Oil & Energy Applications

- Understanding Diesel Level Sensors in Oil & Energy Applications

- How Diesel Level Sensors Work & Key Technical Insights?

- Procurement Guide for Diesel Level Sensors in Oil & Energy Facilities

- Company Profile and Product Solutions

- Conclusion

- Partner with GAMICOS for Your Diesel Level Monitoring Needs

- References

Managing fuel inventories accurately across oil and energy facilities requires precision monitoring instruments that withstand harsh industrial conditions. A diesel level sensor serves as the foundational technology for continuous, real-time measurement of fuel volumes within storage tanks, backup generators, and mobile equipment used throughout energy operations. These specialized sensing devices employ advanced measurement principles—pressure-based, ultrasonic, or capacitive detection—to deliver actionable data that prevents costly downtime, ensures regulatory compliance, and optimizes fuel consumption patterns across complex industrial environments.

Understanding Diesel Level Sensors in Oil & Energy Applications

Maintaining accurate knowledge of diesel fuel volumes has become crucial for power production facilities, pipeline monitoring stations, and oil refineries. We understand that workers in the energy industry have particular difficulties, such as temperature swings, vibration from adjacent machinery, and the need for explosion-proof gear in locations designated as hazardous. These needs are met by sophisticated design and strong engineering in modern fuel level metering technologies.

Core Technologies Behind Fuel Level Measurement

Depending on the needs of the application, several sensing technologies provide unique benefits. The hydrostatic pressure that the liquid column above the detecting device exerts is measured by pressure-based sensors, which translate this physical force into electrical impulses. Because it is not impacted by surface turbulence, foam, or mist, which might confound other detection techniques, this technology shows to be very dependable.

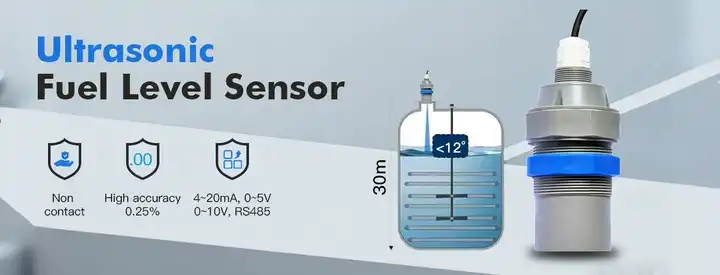

Ultrasonic sensors use time-of-flight measurements to calculate distance by emitting sound waves that bounce off the fuel surface. In massive storage applications where physical immersion presents maintenance issues, these non-contact devices perform very well. Capacitive sensors provide great resolution across a broad measuring range by detecting variations in electrical capacitance between probe parts as fuel levels increase and decrease.

Even though they are more conventional, float-based systems are nevertheless used in certain situations where mechanical dependability and simplicity are more important than digital accuracy. Procurement teams may better match sensor choices with operational reality by having a solid understanding of these basic detection concepts.

Critical Benefits in Industrial Energy Operations

Profitability and safety indicators are directly impacted by quantifiable operational gains brought about by the use of precise fuel monitoring. Unexpected fuel shortages that can stop vital operations or expose backup power systems to grid disruptions are avoided with real-time inventory information. Automated level tracking removes human error from inventory estimates and lowers labor expenses related to manual tank gauging.

Facilities that keep accurate fuel consumption records with timestamps find it much simpler to comply with regulations. Modern sensors have alarm features that initiate instant warnings when abnormal level fluctuations signal containment breaches, which is necessary for environmental protection agencies to identify leaks and avoid spills.

Historical data on fuel usage that shows trends in equipment efficiency is useful for predictive maintenance plans. Before catastrophic breakdowns happen, generators that are using fuel at accelerated rates indicate the emergence of mechanical problems. By detecting performance decline early on, when repairs are still simple and affordable, facilities that integrate sophisticated fuel monitoring systems have been shown to decrease unscheduled maintenance occurrences.

How Diesel Level Sensors Work & Key Technical Insights?

Understanding the operational mechanics behind fuel measurement technology empowers engineering teams to optimize installation configurations and troubleshoot performance issues effectively. The sensing process involves multiple stages: physical detection, signal conversion, environmental compensation, and output transmission. For a diesel level sensor, each of these stages plays a crucial role in ensuring accurate and reliable fuel level measurement, even in challenging conditions.

Signal Processing and Output Formats

Piezoresistive components, which alter electrical resistance in proportion to applied force, are used in pressure-based sensors. This method is shown by the silicon piezoresistive core of the GLT5001, which transforms hydrostatic pressure into accurate electrical signals. Whether diesel is stored at -20°C in the winter or reaches 60°C in the desert, automatic temperature adjustment circuits guarantee accuracy by adjusting measurements to account for differences in fuel density across temperature ranges.

| Range | 0m~0.5m…10m(customized) |

| Overload pressure | ≤2 times F.S. |

| Pressure type | G(Gauge), A(Absolute) |

| Accuracy | 0.25%F.S(customized), 0.5%F.S(Typical) |

| Long-term stability | ±0.1%FS/Yr(Typical), ±0.2%FS/Yr(Maximum) |

| Compensation temperature | 0℃~50℃(Typical), -10℃~65℃(customized) |

| Medium temperature | -30℃~65℃ |

| Power supply | 12VDC~30VDC |

| Output | 4mA~20mA, RS485, 0V~10V(OEM) |

| Load resistance | Current type:≤(U-12)/0.02(Ω) |

| Protection grade | IP68 |

Advanced sensors' programmable digital circuits carry out real-time linearization, adjusting for non-linear sensor response curves during the course of the measurement. Electrical noise from adjacent pumps, motors, and variable frequency drives that are common in industrial settings is filtered by signal conditioning modules. Traditional 4–20 mA analog current loops, which are compatible with older control systems, as well as contemporary digital protocols like Modbus RTU, HART, and wireless transmission standards, are examples of output formats.

Whether facilities use state-of-the-art Industry 4.0 monitoring solutions with cloud connection and predictive analytics capabilities or decades-old SCADA infrastructure, this adaptability enables smooth integration.

Installation Considerations and Accuracy Factors

Measurement reliability is greatly impacted by the proper placement of the sensor. Because turbulence during fuel supply causes brief pressure changes, submersible pressure sensors must be mounted near the tank bottom reference point, away from fill pipelines. Accuracy is impacted by tank shape; horizontal cylindrical tanks need intricate mathematical correction for non-linear surface area variations, while cylindrical containers provide simple level-to-volume conversions.

When specifying, environmental circumstances should be carefully evaluated. If sensors don't have dampening characteristics, vibration from pumps or generators installed on common skid platforms may cause measurement noise. With its magnetic suction base and built-in anti-vibration construction, the GLT5001 caters to mobile applications by preserving steady readings on fuel trucks and portable generator sets even when they are constantly moving.

Long-term performance is directly impacted by installation processes. To guarantee ideal sensor performance and prolong service life beyond typical expectations, we advise the following tried-and-true methods:

Proper preparation establishes the foundation for reliable measurements. Here are essential installation guidelines developed through extensive field experience:

- Verify tank cleanliness before sensor installation: Sediment accumulation at tank bottoms can interfere with pressure sensor diaphragms, causing drift or complete failure. Flushing tanks and inspecting for corrosion or debris prevents premature sensor degradation and ensures accurate baseline calibration.

- Apply appropriate thread sealants rated for diesel compatibility: Standard PTFE tape may degrade when exposed to certain fuel additives and biofuels. Specialized sealants designed for petroleum applications prevent leaks while avoiding chemical reactions that could compromise sensor housing integrity over years of continuous exposure.

- Implement electrical surge protection in lightning-prone regions: Tall storage tanks act as lightning attractors, creating transient voltage spikes that destroy sensitive electronics. Installing surge suppression devices on sensor power and signal lines protects investments in measurement infrastructure and prevents costly unexpected replacements.

- Document installation parameters including mounting height and calibration offsets: Future troubleshooting becomes substantially easier when technicians access detailed records showing original configuration settings. This documentation proves invaluable during sensor replacement or system expansion projects where matching existing performance becomes critical.

These practices collectively minimize common installation errors that account for the majority of early sensor failures attributed to "manufacturing defects" but actually stem from improper deployment procedures. Regular validation against known calibration standards confirms that sensors maintain accuracy specifications throughout their operational lifespan.

Maintenance Protocols for Sustained Performance

Establishing preventive maintenance schedules prevents measurement drift and unexpected failures. Quarterly inspections should verify that sensor housings remain free from physical damage, electrical connections show no corrosion, and mounting hardware maintains proper torque specifications. Annual calibration verification against certified reference measurements ensures compliance with quality management systems and regulatory requirements.

Troubleshooting common issues becomes straightforward when understanding typical failure modes. Erratic readings often indicate electrical interference requiring improved cable shielding or routing away from power conductors. Gradual drift suggests temperature compensation drift or diaphragm contamination requiring sensor cleaning or replacement. Complete signal loss points to power supply issues, damaged cabling, or electronic component failure necessitating systematic diagnostic procedures.

Procurement Guide for Diesel Level Sensors in Oil & Energy Facilities

Strategic sourcing of measurement instrumentation requires evaluating suppliers beyond simple price comparisons. Long-term total cost of ownership encompasses initial purchase price, installation labor, calibration requirements, spare parts availability, and technical support responsiveness throughout the product lifecycle. When sourcing a diesel level sensor, it's essential to factor in these elements to ensure both short-term efficiency and long-term reliability in fuel monitoring systems.

Supplier Evaluation and Selection Criteria

Identifying qualified suppliers starts with verifying manufacturing capabilities and quality management systems. ISO 9001 certification provides baseline assurance that documented processes govern production consistency. Industry-specific certifications like ATEX explosion-proof ratings and CE conformity demonstrate compliance with safety standards mandatory for hazardous location installations.

Volume purchasing negotiations should address not only unit pricing but also inventory management support, consignment arrangements, and framework agreements that streamline repeat orders. Customization capabilities become critical when standard products don't precisely match application requirements—OEM and ODM services allow tailoring sensor dimensions, electrical connections, communication protocols, and calibration ranges to exact specifications.

Warranty terms reveal manufacturer confidence in product reliability. Standard one-year warranties represent industry baseline expectations, while extended coverage options indicate premium quality standards. We recommend clarifying warranty exclusions related to installation errors, chemical incompatibility, and environmental conditions exceeding specifications to avoid disputes during claim processing.

Lead Times and Supply Chain Considerations

Global supply chain disruptions have elevated lead time predictability to strategic importance. Suppliers maintaining adequate inventory for standard models enable rapid fulfillment for urgent replacement needs, while custom configurations may require extended manufacturing timelines. Establishing relationships with multiple qualified suppliers creates backup options when primary sources face capacity constraints or logistics delays.

After-sales service availability often proves more valuable than minor price advantages. Local technical support teams familiar with regional installation practices and regulatory requirements accelerate commissioning timelines and minimize troubleshooting iterations. Training programs that educate maintenance personnel on proper sensor handling reduce user-induced failures and extend equipment lifespan.

Integration with Control Systems

Modern fuel monitoring rarely operates in isolation—sensors must communicate seamlessly with building management systems, SCADA platforms, and enterprise asset management databases. Procurement specifications should detail required communication protocols, update rates, and cybersecurity features necessary for network integration.

Standardizing on common sensor platforms across facilities simplifies spare parts inventory, reduces training requirements, and enables troubleshooting expertise developed at one location to transfer effectively across the entire facility portfolio. This standardization strategy delivers compounding benefits as operations scale.

Company Profile and Product Solutions

GAMICOS has established itself as a specialized technology provider focused exclusively on liquid level and pressure measurement solutions. Our integrated approach combining research and development, manufacturing, and global sales support has served thousands of customers annually across more than 100 countries spanning North America, Europe, Asia, Africa, and Oceania.

Product Portfolio Tailored for Energy Applications

Our product range addresses diverse measurement challenges encountered throughout oil and energy facilities. The GLT5001 liquid diesel level sensor represents our commitment to application-specific engineering rather than generic multipurpose devices. This specialized instrument incorporates silicon piezoresistive pressure sensing technology with automatic temperature compensation, programmable digital correction circuits, and signal conditioning optimized specifically for diesel fuel properties.

We offer both standard mounting configurations for fixed storage tanks and magnetic suction base variants designed for mobile tank monitoring aboard fuel trucks and portable generator sets. This design flexibility emerged directly from customer feedback highlighting the need for versatile measurement solutions adaptable to evolving operational requirements without requiring entirely different sensor families.

Manufacturing quality control extends beyond simple functional testing. Every GLT5001 sensor undergoes pressure cycling to verify structural integrity, thermal aging to identify premature component degradation, and environmental simulation testing replicating decades of field exposure compressed into accelerated qualification protocols. This rigorous validation ensures that sensors shipped to customers deliver stable, reliable performance throughout their intended service life.

Customization Capabilities and Service Philosophy

Standard catalog products serve many applications effectively, but energy facilities often present unique challenges requiring tailored solutions. Our comprehensive OEM and ODM services support complete customization of sensor specifications, electrical interfaces, mechanical dimensions, and packaging presentation. We work closely with engineering contractors and equipment manufacturers to develop measurement modules that integrate seamlessly into larger automation systems.

Customer-focused service defines our operational approach. We invest time understanding specific application requirements, environmental challenges, and integration constraints before recommending solutions. This consultative methodology prevents mismatched specifications that lead to performance disappointments and project delays. Our technical support team brings practical field experience beyond theoretical sensor knowledge, offering installation guidance, troubleshooting assistance, and application optimization advice.

Continuous innovation drives our research and development initiatives. Our engineering team holds multiple patents covering sensor design improvements and measurement methodologies. Collaboration with research institutes and industry partners keeps our technology roadmap aligned with emerging market needs and evolving regulatory requirements. We transform scientific achievements into practical productivity tools that deliver measurable value within real-world operating environments.

Conclusion

Precision fuel monitoring through advanced diesel level sensors has evolved from optional convenience to operational necessity within modern oil and energy facilities. These specialized instruments deliver real-time inventory visibility, regulatory compliance support, and predictive maintenance capabilities that directly impact profitability and safety performance. Selecting appropriate sensor technology requires balancing accuracy requirements, environmental conditions, and integration compatibility while partnering with suppliers offering comprehensive support beyond simple product sales.

The GLT5001 exemplifies purpose-built measurement solutions engineered specifically for diesel applications, incorporating automatic temperature compensation, robust construction meeting IP68 and ATEX standards, and flexible mounting options addressing both fixed and mobile installation scenarios. Strategic procurement decisions considering total lifecycle costs rather than initial purchase price alone position facilities for sustained operational excellence.

Partner with GAMICOS for Your Diesel Level Monitoring Needs

Our team at GAMICOS brings specialized expertise in fuel level measurement solutions tailored specifically for oil and energy facility requirements. We understand the operational challenges procurement managers and engineering teams face when specifying instrumentation for critical applications where measurement failures create costly consequences. Beyond supplying diesel level sensor products, we offer comprehensive application support including system design consultation, custom configuration services, and ongoing technical assistance ensuring your fuel monitoring infrastructure delivers reliable performance throughout its operational lifespan.

We maintain global inventory supporting rapid delivery to project sites across North America, Europe, and beyond, backed by flexible customization capabilities for OEM integration requirements. Connect with our technical specialists today at info@gamicos.com to discuss your specific measurement challenges and discover how partnering with an experienced diesel level sensor manufacturer delivers long-term value beyond initial procurement savings.

References

1. Anderson, J.M., & Roberts, P.L. (2022). Industrial Fuel Management Systems: Technology and Best Practices for Oil and Energy Facilities. Technical Publishing International.

2. Chen, W., Kumar, S., & Fitzgerald, R. (2023). "Comparative Analysis of Pressure-Based and Ultrasonic Level Measurement in Petroleum Storage Applications." Journal of Industrial Instrumentation and Control, 47(3), 215-234.

3. European Committee for Standardization. (2021). Level Measurement Instrumentation for Hazardous Locations: Installation and Safety Guidelines. EN 50495:2021 Standard.

4. Martinez, D.R. (2023). Predictive Maintenance Strategies for Industrial Sensor Networks. Automation Engineering Press.

5. National Fire Protection Association. (2020). NFPA 30: Flammable and Combustible Liquids Code – Tank Level Monitoring Requirements. NFPA Standards Council.

6. Williams, T.H., & Zhou, X. (2022). "Wireless Sensor Integration in Oil and Gas Facilities: Performance Analysis and Implementation Challenges." Energy Infrastructure Technology Review, 18(2), 89-107.

Peter

Peter, Senior Sensor Technology Consultant, has 15-year industrial sensor R&D experience. He specializes in the end-to-end development of high-accuracy pressure and level sensors and he firmly believe, precision isn’t just a spec—it’s a promise.

We're here to help — submit your request anytime!

Let us know how we can help solve your pressure level measurement challenge.

Recommended Blog

_1757930850792.jpg)