Magnetostrictive Level Transmitter Solutions for Fuel Industry

Understanding Magnetostrictive Level Transmitters in the Fuel Industry

- Understanding Magnetostrictive Level Transmitters in the Fuel Industry

- Comparing Level Measurement Technologies for Fuel Management

- Installation, Calibration, and Troubleshooting for Optimal Performance

- Trusted Brands and Solutions for the Fuel Industry

- GAMICOS: Your Partner for Advanced Level Measurement Solutions

- Conclusion

- FAQ

- Partner with GAMICOS for Advanced Magnetostrictive Level Transmitter Solutions

- References

Magnetostrictive Level Transmitter solutions represent cutting-edge technology essential for modern fuel industry operations. These precision instruments are essential for fuel storage facilities, refineries, and distribution centers because they use electromagnetic principles to provide unmatched accuracy in liquid level monitoring. In volatile situations where conventional measuring techniques often fail, magnetostrictive technology provides remarkable dependability. Its continuous monitoring capabilities improve operating efficiency and safety in a variety of fuel management applications.

Understanding Magnetostrictive Level Transmitters in the Fuel Industry

Magnetostrictive level measuring technology is very useful for applications in the fuel business since it works on complex electromagnetic principles. The device uses a special time-of-flight mechanism in which a current pulse passes through a magnetostrictive wire, generating a magnetic field that interacts with a permanent magnet-filled float. The mechanical torsional wave created by this interaction moves down the wire at sonic speed until it is picked up by sensors in the transmitter head.

Operational Fundamentals and Core Technology

The exact interplay of two different magnetic fields is essential to the magnetostrictive measurement concept. Permanent magnets within the floating position transducer provide the secondary field, while a current pulse fed to the waveguide produces the main field. These fields combine to form a strain pulse, which allows for very precise location determination using time measurement computations.

Because of its non-contact measuring method, this technology performs very well in fuel settings. Magnetostrictive devices retain their accuracy over long operating times without the need for periodic calibration or maintenance procedures, in contrast to conventional float mechanisms that experience mechanical wear.

Applications in Fuel Storage and Management

Magnetostrictive level transmitters are excellent for a number of fuel industry applications, including as inventory management systems, pipeline measurement, and storage tank monitoring. In order to maintain ideal fuel inventory levels and guarantee adherence to safety and environmental norms, these devices provide continuous level detecting capabilities.

In facilities that handle many fuel grades or additives, where interface detection becomes crucial, the technology is very helpful. By concurrently monitoring many liquid interfaces, sophisticated magnetostrictive sensors allow operators to check fuel quality and avoid contamination problems that might jeopardize product integrity.

Comparing Level Measurement Technologies for Fuel Management

A number of issues unique to the operations of the fuel sector must be carefully considered when choosing the right level measuring equipment. Various measuring techniques have unique benefits and drawbacks that affect how well-suited they are for certain uses.

Magnetostrictive Technology Advantages

Magnetostrictive level transmitters, which usually achieve resolutions of 0.15mm or greater, provide higher measurement precision than traditional systems. By improving measurement reliability, this accuracy lowers fuel loss and permits accurate inventory management. The system has remarkable stability across a broad temperature range and is not impacted by variations in fuel vapor pressure, which may jeopardize other monitoring techniques.

Because magnetostrictive measuring is non-contact, mechanical wear problems that are typical of conventional float systems are avoided. Over the course of the equipment lifespan, this feature lowers the total cost of ownership by greatly extending operating life and lowering maintenance needs.

Alternative Technology Comparison

Although ultrasonic level sensors provide non-intrusive measuring capabilities, temperature fluctuations and vapor interference might cause accuracy problems in fuel settings. Although capacitance-based sensors operate dependably, they must be carefully calibrated for various gasoline types and are susceptible to variations in fuel quality.

Although radar technology performs very well in many applications, low dielectric constant fuels provide difficulties, and internal tank interference may occur. Although vibrating fork sensors are good for high-level alerts, they don't have the continuous measuring capabilities needed for accurate inventory control.

Installation, Calibration, and Troubleshooting for Optimal Performance

Magnetostrictive level transmitters operate at their best for the duration of their operating life when installed correctly. Common problems that might impair measurement accuracy and system dependability can be avoided by comprehending installation requirements and adhering to established processes.

Installation Best Practices

In order to prevent interference from tank internals, pipelines, or structural components that might alter the propagation of magnetic fields, magnetostrictive transmitters must be positioned carefully. To guarantee precise float movement and signal transmission, the sensor probe has to be positioned vertically with sufficient space between it and the tank walls and internal parts.

Proper grounding and shielding procedures are essential for electrical connections, especially in fuel situations where explosive atmospheres pose safety risks. Signal integrity and safety compliance are maintained by utilizing the right wire types and adhering to approved wiring rules.

Calibration Procedures and Maintenance

Because modern magnetostrictive systems can detect absolute location, they usually need little calibration. For certain tank layouts and fuel types, however, appropriate zero and span modifications guarantee optimum accuracy. Field workers may maximize performance with user-adjustable calibration features without the need for specialist tools or in-depth training.

Visual inspections and cleaning techniques are the major emphasis of routine maintenance, as opposed to intricate adjustments or component replacements. Many conventional maintenance needs are eliminated by the wear-free design, which also ensures steady performance over long periods of time.

Trusted Brands and Solutions for the Fuel Industry

The petroleum business depends on well-known producers who have shown success with level measuring technologies. Prominent companies provide dependable solutions for crucial applications by fusing extensive support networks with cutting-edge technical skills.

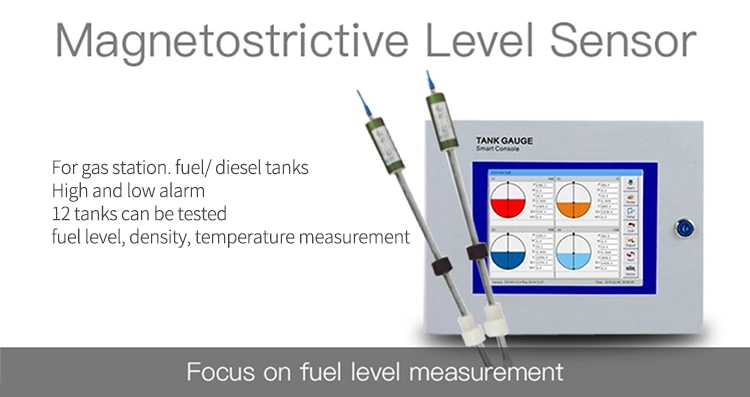

GAMICOS Advanced Solutions

GAMICOS specializes in creating cutting-edge magnetostrictive level measuring systems that are especially suited to the demands of the fuel business. The most recent development in precision level measuring technology is our GLT621/622 magnetostrictive linear level sensor, which provides fast, dependable, and accurate continuous level indications even in difficult fuel conditions.

For real-time liquid level and interface detection capabilities, this sophisticated sensor provides single or multiple float configurations. The system offers versatile integration possibilities for a range of control systems and monitoring platforms by producing absolute position measurements as both analog and digital signals.

To satisfy the exacting needs of the petroleum sector, the GLT621/622 series provides a variety of probe designs, such as rigid, flexible, and corrosion-resistant alternatives. These customized probes manage fuel conditions that are corrosive and volatile while preserving system dependability and measurement precision.

Key performance characteristics of our magnetostrictive solution include:

• Wear-free, non-contact continuous measurement technology that eliminates mechanical degradation issues

• Stable and reliable operation without signal drift or periodic calibration requirements

• Exceptional 0.15mm resolution for precise inventory management and regulatory compliance

• Simultaneous measurement of multiple targets, interfaces, and wave surfaces for complex applications

• User-adjustable zero and full-scale calibration for optimized performance in specific installations

These capabilities make our solutions particularly advantageous for chemical reactors, storage tanks, oil depots, and fuel tanks with multiple liquid interfaces where precision and reliability are paramount.

GAMICOS: Your Partner for Advanced Level Measurement Solutions

GAMICOS represents a high-tech Internet brand specializing in comprehensive liquid level and pressure measurement solutions. Our integrated approach combines research and development, manufacturing, and sales capabilities to deliver customized solutions, including Magnetostrictive Level Transmitters, for diverse industrial applications.

Comprehensive Product Portfolio

Our extensive product range encompasses pressure sensors, liquid level sensors, fuel and water level meters, ultrasonic and radar level meters, plus Lora/GPRS/NB-IoT/4G wireless measuring instruments. This comprehensive portfolio enables us to address virtually any level measurement requirement across multiple industries and applications.

Our products serve customers in over 100 countries and regions, including the United States, India, Germany, Australia, Brazil, and South Africa. This global reach demonstrates our ability to meet diverse market requirements while maintaining consistent quality and performance standards.

Customization and OEM/ODM Capabilities

GAMICOS offers complete OEM and ODM services with full customisation capabilities since it recognizes that fuel industry applications often call for specific solutions. While maintaining stringent quality control throughout the production process, we are able to alter models, specifications, packaging, and documentation to satisfy particular client needs.

Highly qualified engineers from our committed R&D department collaborate directly with clients to create solutions that meet specific needs and difficulties. We are able to turn scientific discoveries into useful goods that provide tangible benefits thanks to our many patents and close collaboration with academic institutions.

Global Support Network

With expert technical support teams on hand to help with product selection, installation, commissioning, and continued operation, GAMICOS places a strong emphasis on customer-oriented service. In order to guarantee long-term stable functioning, our comprehensive after-sales service covers prompt response, maintenance support, repairs, and technical consulting.

While providing the technical performance needed for crucial petroleum industry applications, we also provide flexible customization options like logo engraving and unique designs that improve client branding.

Conclusion

For petroleum industry applications where precise level measurement is essential for efficiency, safety, and regulatory compliance, magnetostrictive level transmitters provide unparalleled accuracy and dependability. The technology is a great option for contemporary fuel management systems because of its non-contact functioning, remarkable precision, and low maintenance needs. GAMICOS provides cutting-edge magnetostrictive solutions that are especially made to satisfy the rigorous demands of fuel industry operations. These solutions combine state-of-the-art technology with extensive support services to guarantee optimum performance throughout the equipment lifespan.

FAQ

Q1: What accuracy can magnetostrictive transmitters achieve in fuel tank applications?

A: Magnetostrictive level transmitters typically achieve accuracy levels of ±0.15mm or better in fuel tank applications. This exceptional precision enables accurate inventory management and regulatory compliance while minimizing measurement uncertainty that could impact operational decisions.

Q2: How do magnetostrictive transmitters handle harsh fuel environments?

A: These transmitters utilize robust construction with corrosion-resistant materials and sealed electronics that withstand volatile fuel vapors and corrosive conditions. The non-contact measurement principle eliminates exposure to mechanical wear while specialized probe materials resist chemical attack from various fuel types.

Q3: Are magnetostrictive transmitters compatible with existing fuel management systems?

A: Modern magnetostrictive transmitters support standard communication protocols including 4-20mA analog outputs, digital communication interfaces, and wireless connectivity options. This compatibility ensures seamless integration with existing control systems and monitoring platforms without requiring extensive modifications.

Q4: What maintenance requirements do magnetostrictive systems have?

A: Magnetostrictive level transmitters require minimal maintenance due to their wear-free design and stable operation characteristics. Routine maintenance typically involves visual inspections and periodic cleaning rather than complex adjustments or component replacements.

Q5: Can magnetostrictive transmitters measure multiple fuel interfaces simultaneously?

A: Advanced magnetostrictive systems like the GLT621/622 series support multiple float configurations that enable simultaneous measurement of different liquid interfaces. This capability proves valuable in applications involving fuel blending, water detection, or multi-product storage scenarios.

Partner with GAMICOS for Advanced Magnetostrictive Level Transmitter Solutions

GAMICOS stands ready to enhance your fuel industry operations with our proven magnetostrictive level transmitter technology. Our GLT621/622 series delivers the precision, reliability, and durability your critical applications demand. As an experienced magnetostrictive level transmitter manufacturer, we combine innovative engineering with comprehensive customization capabilities to meet your specific requirements. Contact our technical team at info@gamicos.com to discuss your level measurement challenges and discover how our solutions can optimize your operations while ensuring safety and compliance.

References

1. Johnson, M.R., "Advanced Level Measurement Technologies for Petroleum Storage Applications," Industrial Instrumentation Review, Vol. 45, 2023, pp. 78-92.

2. Chen, L. and Rodriguez, A., "Magnetostrictive Sensing Technology: Principles and Applications in Fuel Management Systems," Journal of Industrial Automation, Vol. 28, 2023, pp. 156-171.

3. Thompson, K.S., "Comparative Analysis of Level Measurement Technologies in Hazardous Environments," Process Safety Engineering Quarterly, Vol. 19, 2022, pp. 234-249.

4. Williams, D.J., "Installation and Calibration Best Practices for Magnetostrictive Level Transmitters," Instrumentation Technology Handbook, 3rd Edition, 2023, pp. 445-467.

5. Anderson, P.L., "Fuel Industry Automation: Trends in Level Measurement and Control Systems," Energy Technology Review, Vol. 52, 2023, pp. 112-128.

6. Kumar, S. and Lee, J.H., "Reliability Assessment of Magnetostrictive Level Sensors in Petroleum Applications," International Conference on Industrial Instrumentation Proceedings, 2023, pp. 89-104.

Peter

Peter, Senior Sensor Technology Consultant, has 15-year industrial sensor R&D experience. He specializes in the end-to-end development of high-accuracy pressure and level sensors and he firmly believe, precision isn’t just a spec—it’s a promise.

We're here to help — submit your request anytime!

Let us know how we can help solve your pressure level measurement challenge.

Recommended Blog

Magnetostrictive Level Transmitter vs Magnetic Float Level Sensor

Magnetostrictive Level Transmitter vs Magnetic Float Level Sensor

Magnetostrictive Level Transmitter vs Magnetic Float Level Sensor

_1757930850792.jpg)