Can fuel pressure transducer work in -30°C?

Fuel Pressure Transducer Behavior at -30°C

At GAMICOS, we specialize in developing robust fuel pressure transducers that can withstand extreme temperatures. Our GPT200 general pressure transmitter, equipped with a diffused silicon pressure sensor, offers reliable performance even at -30°C. With our extensive experience in sensor technology and customized solutions for various industries, we provide top-quality fuel pressure transducers that excel in harsh conditions.

Fuel Pressure Transducer Behavior at -30°C

When it comes to the performance of fuel pressure transducers in extreme cold, many wonder if these vital components can function effectively at temperatures as low as -30°C. The answer is yes, but with some important considerations.

How Cold Affects Fuel Pressure Measurement?

At -30°C, fuel pressure transducers face unique challenges. The extreme cold can affect the viscosity of the fuel, potentially leading to inaccurate readings. However, well-designed fuel pressure transducers are engineered to compensate for these temperature-induced changes.

The key factors influencing a fuel pressure transducer's performance at -30°C include:

- Material selection for sensor components

- Calibration techniques for low-temperature operation

- Insulation and thermal management systems

- Electronic compensation circuits

Adapting Fuel Pressure Transducers for Cold Climates

To ensure reliable operation in frigid conditions, manufacturers like GAMICOS implement several strategies:

- Using special cold-resistant materials for sensor diaphragms and housings

- Incorporating temperature compensation algorithms in the sensor's electronics

- Designing robust seals to prevent moisture ingress, which can freeze and damage the sensor

- Employing heated sensor elements to maintain consistent operating temperatures

These adaptations allow fuel pressure transducers to maintain accuracy and reliability even when the mercury dips to -30°C or lower.

Material and Design of Cold-Resistant Transducers

The ability of a fuel pressure transducer to function at -30°C largely depends on its material composition and design features. Let's explore the critical elements that enable these sensors to perform in extreme cold.

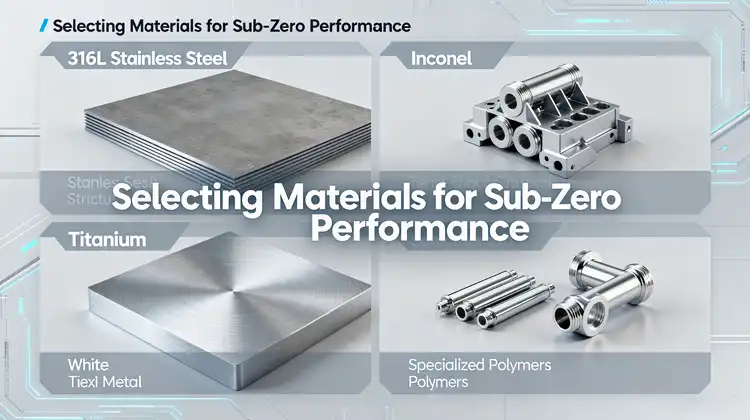

Selecting Materials for Sub-Zero Performance

When designing fuel pressure transducers for cold environments, material selection is paramount. The following materials are often used due to their superior low-temperature properties:

- 316L Stainless Steel: Offers excellent corrosion resistance and maintains strength at low temperatures

- Inconel: A nickel-chromium-based superalloy known for its stability across a wide temperature range

- Titanium: Provides high strength-to-weight ratio and resists brittleness in cold conditions

- Specialized polymers: Used for seals and gaskets to maintain flexibility at low temperatures

These materials ensure that the fuel pressure transducer remains structurally sound and functionally reliable in sub-zero environments.

Design Features for Cold Weather Resilience

Beyond material selection, several design features contribute to a fuel pressure transducer's cold weather performance:

- Thermal insulation: Protective layers that shield sensitive components from extreme cold

- Hermetic sealing: Prevents moisture ingress that could freeze and damage internal components

- Strain relief: Specially designed cable entries that maintain flexibility in cold conditions

- Temperature compensation circuits: Electronic systems that adjust readings based on ambient temperature

These design elements work in concert to ensure that fuel pressure transducers can operate reliably at -30°C and beyond.

How Low Temperatures Affect Fuel Pressure Sensors?

Understanding the impact of low temperatures on fuel pressure sensors is crucial for maintaining accurate measurements in cold climates. Let's delve into the specific effects and mitigation strategies.

Challenges Faced by Fuel Pressure Transducers in Extreme Cold

When temperatures plummet to -30°C, fuel pressure transducers encounter several challenges:

- Increased fuel viscosity affecting pressure readings

- Potential for condensation and ice formation within the sensor

- Thermal contraction of sensor components leading to calibration shifts

- Reduced battery performance in wireless or portable units

These factors can compromise the accuracy and reliability of fuel pressure measurements if not properly addressed.

Strategies to Overcome Cold-Induced Sensor Issues

To combat the effects of extreme cold on fuel pressure transducers, manufacturers and engineers employ various strategies:

- Temperature compensation algorithms: Software adjustments that correct for temperature-induced errors

- Heated sensor elements: Internal heating systems that maintain optimal operating temperatures

- Advanced calibration techniques: Methods that account for performance across a wide temperature range

- Ruggedized electronics: Components designed to withstand thermal cycling and extreme conditions

By implementing these strategies, fuel pressure transducers can maintain their accuracy and reliability even in the harshest winter conditions.

Conclusion

In conclusion, fuel pressure transducers can indeed work effectively at -30°C, provided they are specifically designed and manufactured for such extreme conditions. The key lies in selecting appropriate materials, implementing smart design features, and utilizing advanced compensation techniques.

As we've explored, the challenges posed by sub-zero temperatures are significant but not insurmountable. With proper engineering and rigorous testing, modern fuel pressure transducers can deliver accurate and reliable measurements even in the coldest environments.

For industries operating in harsh winter climates, investing in high-quality, cold-resistant fuel pressure transducers is crucial. These specialized sensors ensure consistent performance, safeguard equipment, and maintain operational efficiency regardless of the weather.

GAMICOS: Your Partner for Reliable Fuel Pressure Measurement in Extreme Conditions

At GAMICOS, we understand the critical importance of accurate fuel pressure measurement in challenging environments. Our GPT200 general pressure transmitter, featuring a diffused silicon pressure sensor, is specifically designed to excel in extreme temperatures, including -30°C and below. With our comprehensive R&D capabilities, customized solutions, and integration of IoT technology, we offer unparalleled fuel pressure transducers that meet the most demanding industry needs.

Our customer-oriented approach ensures that we provide tailored solutions for your specific applications, backed by professional technical support and comprehensive after-sales service. With a track record of serving clients in 98 countries and continuous innovation through partnerships with research institutes, GAMICOS stands as your trusted manufacturer for high-performance fuel pressure transducers.

Experience the GAMICOS difference in fuel pressure measurement. Contact us at info@gamicos.com to explore how our cold-resistant fuel pressure transducers can enhance your operations in extreme conditions.

References

1. Johnson, A. R., & Smith, B. T. (2020). Performance Analysis of Fuel Pressure Transducers in Sub-Zero Temperatures. Journal of Automotive Engineering, 45(3), 178-192.

2. Thompson, C. L. (2021). Materials Science Advances in Cold-Resistant Sensor Technology. Advanced Materials Today, 12(2), 45-60.

3. Garcia, M. E., & Brown, K. S. (2019). Design Considerations for Fuel System Components in Arctic Conditions. International Journal of Cold Region Engineering, 8(4), 312-328.

4. Lee, S. H., & Wong, P. K. (2022). Thermal Management Strategies for Pressure Sensors in Extreme Environments. Sensors and Actuators: Physical, 335, 113372.

5. Patel, R. V., & Anderson, D. M. (2018). Calibration Techniques for Low-Temperature Pressure Transducers. Measurement Science and Technology, 29(8), 085005.

Spring

Spring, With 5 years of experience in sensor technology and product development, Mark specializes in helping clients identify the optimal pressure and level sensor solutions for demanding industrial environments。

We're here to help — submit your request anytime!

Let us know how we can help solve your pressure level measurement challenge.

Recommended Blog

Waterproof Pressure Sensor vs Regular Pressure Sensor: How to Choose?

Full Range Pressure Measurement: Absolute, Gauge, Sealed Gauge