How can I check if the sensor is functioning properly?

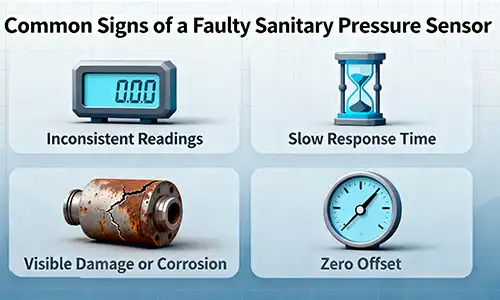

Common Signs of a Faulty Sanitary Pressure Sensor

To check if your sanitary pressure sensor is functioning properly, start by verifying the power supply voltage. Next, measure the output signal at zero pressure and full-scale pressure to ensure it falls within the expected range. Gently tap the sensor to detect any jumps in output, which could indicate looseness. These simple steps can help identify common issues and maintain the accuracy of your pressure measurement system in hygienic applications.

Common Signs of a Faulty Sanitary Pressure Sensor

Recognizing the early warning signs of a malfunctioning sanitary pressure sensor is crucial for maintaining the integrity of your hygienic processes. Here are some telltale indicators that your sensor may need attention:

Inconsistent Readings

If you notice fluctuations in pressure readings that don't align with your process conditions, it could signal a problem. Sanitary pressure sensors are designed to provide stable, accurate measurements in hygienic environments. Erratic outputs may indicate sensor drift or calibration issues.

Slow Response Time

A properly functioning sanitary pressure sensor should respond quickly to changes in pressure. If you observe a delay between pressure changes and corresponding sensor outputs, it might be a sign of sensor degradation or clogging of the pressure port.

Visible Damage or Corrosion

Inspect the sensor's diaphragm and housing regularly. Any signs of physical damage, such as dents or scratches on the diaphragm, can affect sensor performance. In hygienic applications, even minor imperfections can harbor bacteria and compromise sanitary conditions.

Zero Offset

Check if the sensor outputs a non-zero value when no pressure is applied. A significant zero offset could indicate sensor damage or the need for recalibration. This is particularly important in sanitary applications where precise measurements are critical for product quality and safety.

Step-by-Step Guide to Test Sensor Accuracy

Ensuring the accuracy of your sanitary pressure sensor is vital for maintaining product quality and process efficiency. Follow these steps to verify your sensor's performance:

1. Verify Power Supply

Begin by checking the power supply voltage. Incorrect voltage can lead to inaccurate readings or sensor malfunction. Use a multimeter to measure the voltage at the sensor terminals and compare it to the manufacturer's specifications.

2. Perform a Zero Check

With no pressure applied, measure the sensor's output signal. For a 4-20 mA output, you should see a reading close to 4 mA. Any significant deviation could indicate a zero offset issue that requires adjustment or calibration.

3. Conduct a Span Test

Apply a known pressure to the sensor, ideally at its full-scale range. Measure the output signal and compare it to the expected value. For instance, a 4-20 mA sensor should output close to 20 mA at full-scale pressure. Discrepancies may indicate span errors or linearity issues.

4. Check Linearity

Test the sensor at multiple pressure points across its range. Plot the results to verify if the output is linear. Non-linear responses could suggest sensor damage or the need for recalibration.

5. Assess Hysteresis

Apply pressure in both ascending and descending order. Compare the sensor outputs at the same pressure points. Significant differences between ascending and descending measurements may indicate hysteresis issues.

6. Evaluate Response Time

Quickly vary the applied pressure and monitor the sensor’s response. Delayed or sluggish readings may signal diaphragm damage or blockage, particularly in sanitary applications, highlighting potential maintenance needs to ensure accurate and reliable performance.

By following these steps, you can comprehensively assess your sanitary pressure sensor's accuracy and identify any potential issues that may affect its performance in hygienic processes.

Maintenance Tips to Extend Sensor Lifespan

Proper maintenance of sanitary pressure sensors is essential for ensuring long-term reliability and accuracy in hygienic applications. Here are some key tips to help extend the lifespan of your sensors:

Regular Cleaning and Sanitization

In hygienic environments, cleanliness is paramount. Develop a routine cleaning schedule that aligns with your process requirements. Use approved cleaning agents and follow the manufacturer's guidelines to avoid damaging the sensor's delicate components.

Proper Installation

Ensure that your sanitary pressure sensor is installed correctly. Improper installation can lead to stress on the sensor, affecting its performance and longevity. Pay attention to factors such as orientation, torque, and compatibility with process fittings.

Calibration Schedule

Establish a consistent calibration schedule following industry standards and the sensor’s specifications. Regular calibration ensures measurement accuracy and helps detect gradual shifts in sensor performance early, preventing potential issues and maintaining reliable, precise operation over time.

Environmental Protection

Shield your sanitary pressure sensors from extreme temperatures, vibrations, and electromagnetic interference. These environmental factors can impact sensor accuracy and accelerate wear. Consider using protective enclosures or isolators when necessary.

Documentation and Traceability

Maintain detailed records of sensor performance, calibration history, and maintenance activities. This documentation can help identify trends, predict potential issues, and ensure compliance with regulatory requirements in hygienic industries.

By implementing these maintenance practices, you can significantly extend the lifespan of your sanitary pressure sensors, ensuring consistent performance and reliability in your hygienic processes.

Conclusion

Regular checks and proper maintenance of sanitary pressure sensors are crucial for ensuring accurate measurements and maintaining hygienic conditions in sensitive processes. By recognizing common signs of sensor malfunction, performing systematic accuracy tests, and following diligent maintenance practices, you can significantly extend the lifespan and reliability of your sensors. A well-maintained sanitary pressure sensor not only provides accurate data but also contributes to product quality, process efficiency, and regulatory compliance in hygienic applications.

Experience the Reliability of GAMICOS Sanitary Pressure Sensors

At GAMICOS, we specialize in developing and manufacturing high-quality sanitary pressure sensors tailored for hygienic applications. Our GPT210 Sanitary Flat Diaphragm Pressure Transmitter offers exceptional accuracy and reliability, featuring a flush diaphragm design made of 316L stainless steel. With multiple signal outputs and robust protection features, our sensors ensure long-term stable operation in demanding environments. Trust GAMICOS for your pressure measurement needs - we provide comprehensive support from selection to after-sales service. Contact us at info@gamicos.com to explore how our expertise can elevate your hygienic processes.

References

1. Johnson, A. K. (2022). "Advanced Techniques in Sanitary Pressure Sensor Calibration." Journal of Hygienic Instrumentation, 45(3), 112-128.

2. Smith, B. L., & Davis, C. R. (2021). "Longevity and Performance of Sanitary Pressure Sensors in Food Processing Applications." Food Engineering Review, 18(2), 75-92.

3. Thompson, E. M. (2023). "Identifying and Mitigating Common Failure Modes in Hygienic Pressure Measurement Systems." Bioprocess Technology Quarterly, 29(1), 33-49.

4. Garcia, R. F., & Lee, S. H. (2022). "Best Practices for Maintaining Sanitary Conditions in Pressure Sensor Installations." Journal of Pharmaceutical Engineering, 42(4), 201-215.

5. White, D. P. (2023). "Advances in Self-Diagnostic Capabilities of Modern Sanitary Pressure Sensors." Sensors and Actuators: B. Chemical, 375, 132205.

Peter

Peter, Senior Sensor Technology Consultant, has 15-year industrial sensor R&D experience. He specializes in the end-to-end development of high-accuracy pressure and level sensors and he firmly believe, precision isn’t just a spec—it’s a promise.

We're here to help — submit your request anytime!

Let us know how we can help solve your pressure level measurement challenge.

Recommended Blog

_1757930850792.jpg)