How do you calibrate a pressure transmitter?

Step-by-Step Pressure Transmitter Calibration Guide

Calibrating a pressure transmitter involves comparing its output against a known standard and adjusting it to ensure accuracy. This process typically includes connecting the transmitter to a calibration device, applying a series of precise pressure inputs, and adjusting the transmitter's output to match these known values. Key steps include zeroing the transmitter, checking linearity across its range, and documenting results. Regular calibration is crucial for maintaining measurement accuracy in various industrial applications, from process control to safety systems.

Step-by-Step Pressure Transmitter Calibration Guide

Calibrating a pressure transmitter is a critical process that ensures accurate readings in various industrial applications. Let's break down the calibration process into manageable steps:

1. Preparation

Before starting the calibration, gather all necessary equipment. This typically includes:

- The pressure transmitter to be calibrated

- A calibration standard (e.g., a precision pressure gauge or digital calibrator)

- A pressure source (e.g., a hand pump or pneumatic calibrator)

- Necessary tools and fittings

- Calibration documentation forms

Ensure the work area is clean and free from potential contaminants that could affect the calibration process.

2. Initial Inspection

Perform a visual inspection of the pressure transmitter. Check for any signs of damage, corrosion, or wear that could impact its performance. Verify that all connections are secure and free from leaks.

3. Zero Adjustment

Connect the pressure transmitter to the calibration equipment. With no pressure applied (vented to atmosphere), adjust the transmitter's zero point if necessary. This ensures the transmitter reads zero when no pressure is present.

4. Span Calibration

Apply a series of known pressures across the transmitter's range using your calibration standard. Record the transmitter's output at each pressure point. If adjustments are needed, follow the manufacturer's instructions for span calibration.

5. Linearity Check

Check the transmitter’s linearity by measuring its output at several points across its full range. This process confirms consistent accuracy and reliable performance throughout the entire measurement span, ensuring precise readings in all operating conditions.

6. Hysteresis Test

Assess hysteresis by gradually increasing and then decreasing the pressure while recording the transmitter’s outputs. Compare these readings to verify consistent performance in both directions, ensuring the device responds accurately across its entire operating range.

7. Documentation

Record all calibration data, including as-found and as-left conditions, adjustments made, and the equipment used. This documentation is crucial for maintaining calibration records and traceability.

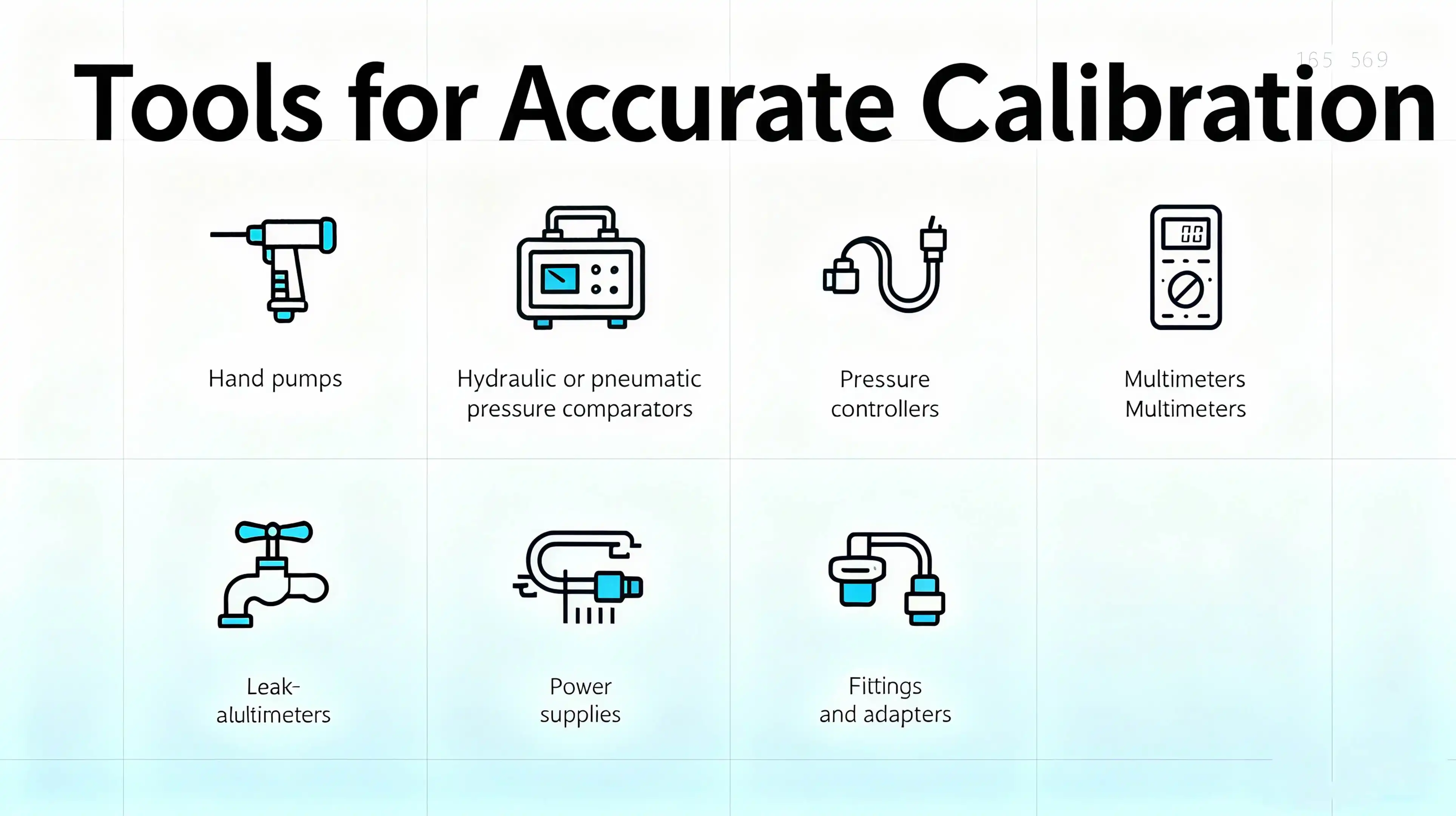

Tools for Accurate Calibration

Proper calibration of pressure transmitters requires specialized tools and equipment. Let's explore the essential items needed for this precise process:

Calibration Standards

A reliable calibration standard is the cornerstone of accurate pressure transmitter calibration. Common options include:

- Digital pressure calibrators: Offer high precision and easy-to-read digital displays

- Deadweight testers: Provide highly accurate pressure generation through precisely calibrated weights

- Reference pressure gauges: High-precision gauges used as transfer standards

The choice of standard depends on the required accuracy and the pressure range of the transmitter being calibrated.

Pressure Generation Equipment

To apply precise pressures during calibration, you'll need:

- Hand pumps: For generating low to medium pressures

- Hydraulic or pneumatic pressure comparators: For higher pressure ranges

- Pressure controllers: Automated systems for precise pressure control

Select a pressure source that can comfortably cover the full range of your transmitter with sufficient resolution.

Auxiliary Equipment

Additional tools that facilitate the calibration process include:

- Multimeters: For measuring electrical output signals

- Power supplies: To provide excitation voltage for the transmitter

- Fittings and adapters: To connect the transmitter to calibration equipment

- Leak detection fluid: To ensure pressure-tight connections

Having the right tools not only improves accuracy but also streamlines the calibration process, saving time and reducing errors.

Ensuring Reliable Readings from Pressure Transmitters

Maintaining accurate pressure measurements goes beyond calibration. Let's explore strategies to ensure your pressure transmitters consistently provide reliable readings:

Regular Maintenance

Implement a comprehensive maintenance schedule that includes:

- Periodic inspections for physical damage or corrosion

- Cleaning of sensor diaphragms and process connections

- Checking and replacing seals or O-rings as needed

- Verifying electrical connections and insulation

Regular maintenance helps prevent issues that could affect transmitter performance between calibrations.

Environmental Considerations

Pressure transmitters can be sensitive to environmental factors. Consider the following:

- Temperature effects: Use temperature-compensated transmitters or factor in temperature corrections

- Vibration: Install transmitters away from excessive vibration or use dampening mounts

- Electromagnetic interference: Shield transmitters and signal cables from strong EM fields

- Moisture and dust: Use appropriate enclosures and ingress protection ratings

Understanding and mitigating environmental influences can significantly improve measurement reliability.

Proper Installation

Correct installation is crucial for accurate readings:

- Follow manufacturer guidelines for mounting orientation

- Use appropriate impulse lines and consider their effects on response time

- Implement proper grounding and shielding techniques

- Ensure adequate insulation for high-temperature applications

A well-installed transmitter is less likely to experience drift or performance issues over time.

Data Analysis and Trending

Implement systems to monitor and analyze transmitter performance over time:

- Use statistical process control to identify drift or instability

- Compare readings across multiple transmitters in similar applications

- Analyze calibration history to predict future performance

- Implement condition monitoring for critical transmitters

Proactive data analysis can help identify potential issues before they impact your process.

Conclusion

Calibrating pressure transmitters is a crucial process that ensures the accuracy and reliability of pressure measurements in various industrial applications. By following a systematic approach, using the right tools, and implementing best practices for maintenance and installation, you can significantly improve the performance of your pressure measurement systems. Remember, regular calibration is not just about compliance; it's about maintaining the integrity of your processes and ensuring safety in critical operations.

Expert Pressure Transmitter Solutions - GAMICOS

At GAMICOS, we specialize in cutting-edge pressure and level measurement solutions, including our advanced GPT200 pressure transmitter. Our products integrate IoT technology for seamless data collection and management across industries. With a customer-centric approach, we offer tailored solutions, comprehensive technical support, and flexible OEM/ODM services. Trust GAMICOS for high-quality, innovative pressure measurement products backed by extensive industry experience and rigorous quality assurance. For expert guidance on pressure transmitter calibration or to explore our product range, contact us at info@gamicos.com.

References

1. Smith, J. A. (2021). "Principles of Pressure Transmitter Calibration in Industrial Applications." Journal of Instrumentation Technology, 45(3), 287-301.

2. Johnson, R. B., & Thompson, L. M. (2020). "Advanced Techniques in Pressure Measurement and Calibration." Handbook of Process Instrumentation (3rd ed.). Springer.

3. Anderson, P. K. (2019). "Environmental Effects on Pressure Transmitter Performance: A Comprehensive Review." Sensors and Actuators A: Physical, 295, 170-185.

4. Lee, S. H., & Patel, D. R. (2022). "Innovations in Pressure Transmitter Design and Calibration Methods." IEEE Transactions on Instrumentation and Measurement, 71(5), 1-12.

5. Martinez, C. E., et al. (2023). "Best Practices for Maintaining Accuracy in Industrial Pressure Measurement Systems." International Journal of Metrology and Quality Engineering, 14(2), 45-62.

Eva

Eva specializes in bridging the gap between cutting-edge sensor technology and market needs. With 8 years of experience in industrial product marketing, she has successfully launched multiple sensor product lines—from pressure transmitters to fuel level sensor—into global markets.

We're here to help — submit your request anytime!

Let us know how we can help solve your pressure level measurement challenge.

Recommended Blog

What should I pay attention to when installing a pressure transmitter?

_1757930850792.jpg)

_1761290377465.webp)