Installation Tips for Differential Pressure Transducers in Pipelines

Proper Placement of Differential Pressure Transducers

Installing differential pressure transducers in pipelines requires careful attention to detail and proper techniques. Correct placement, accurate piping connections, and avoiding common errors are crucial for optimal performance. This guide provides essential tips for installing differential pressure transducers in pipeline systems, ensuring accurate measurements and reliable operation across various industrial applications.

Proper Placement of Differential Pressure Transducers

Selecting the Ideal Location

When installing a differential pressure transducer in a pipeline, choosing the right location is paramount. The ideal placement should be:

- Away from turbulence-inducing elements like valves, elbows, or reducers

- At least 10 pipe diameters downstream and 5 pipe diameters upstream from flow disturbances

- In a straight section of pipe to ensure laminar flow

- Easily accessible for maintenance and calibration

Proper placement ensures that the differential pressure transducer captures accurate readings, unaffected by flow irregularities.

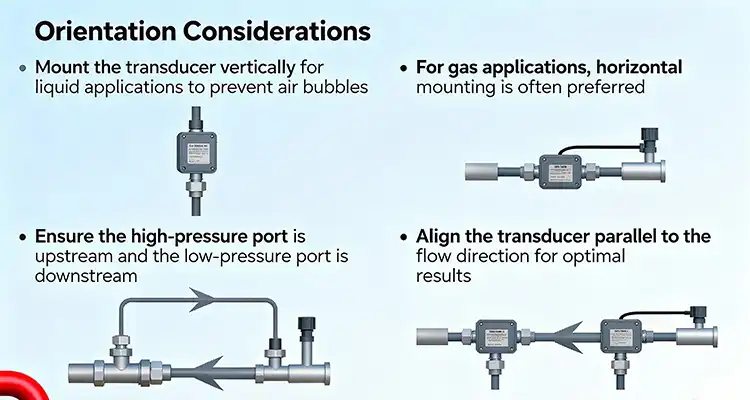

Orientation Considerations

The orientation of the differential pressure transducer can significantly impact its performance. Consider these points:

- Mount the transducer vertically for liquid applications to prevent air bubbles

- For gas applications, horizontal mounting is often preferred

- Ensure the high-pressure port is upstream and the low-pressure port is downstream

- Align the transducer parallel to the flow direction for optimal results

Correct orientation minimizes measurement errors and enhances the longevity of the differential pressure transducer.

Environmental Factors

Environmental conditions play a crucial role in the performance of differential pressure transducers. Consider:

- Protecting the transducer from extreme temperatures

- Shielding it from vibration and mechanical shock

- Ensuring proper insulation in outdoor installations

- Providing adequate ventilation to prevent moisture accumulation

Addressing these environmental factors helps maintain the accuracy and reliability of the differential pressure transducer over time.

Correct Piping Connections for Accurate Measurements

Proper Sizing of Impulse Lines

Impulse lines connect the differential pressure transducer to the pipeline. Proper sizing is crucial:

- Use short, direct impulse lines to minimize lag and improve response time

- Ensure consistent diameter throughout the impulse lines

- Size the lines appropriately for the fluid viscosity and flow rate

- Consider using tubing instead of pipe for better flexibility and easier installation

Correctly sized impulse lines ensure accurate pressure transmission to the differential pressure transducer, enhancing measurement precision.

Implementing Proper Valving

Valves play a crucial role in the installation and maintenance of differential pressure transducers:

- Install isolation valves on both high and low-pressure sides

- Use a manifold with equalizing valve for easy zeroing and calibration

- Consider adding bleed valves for purging air or sediment

- Ensure all valves are rated for the system's maximum pressure

Proper valving allows for safe isolation, easy maintenance, and accurate calibration of the differential pressure transducer.

Sealing and Leak Prevention

Preventing leaks is crucial for maintaining the integrity of differential pressure measurements:

- Use appropriate thread sealants or gaskets at all connections

- Ensure proper tightening of all fittings without over-tightening

- Implement regular leak checks using soap solution or specialized leak detectors

- Consider using compression fittings for easier installation and maintenance

Effective sealing prevents measurement errors and ensures the long-term reliability of the differential pressure transducer installation.

Avoiding Common Installation Errors in Pipelines

Preventing Air Entrapment

Air pockets in the system can lead to inaccurate readings from the differential pressure transducer:

- Install vent valves at high points to release trapped air

- Slope impulse lines upward (at least 1:10) for liquid applications

- Use larger diameter impulse lines for viscous fluids to prevent air entrapment

- Regularly purge the system to remove any accumulated air

Eliminating air entrapment ensures consistent and accurate pressure measurements across the differential pressure transducer.

Addressing Temperature Effects

Temperature fluctuations can impact the accuracy of differential pressure transducers:

- Use insulation or heat tracing on impulse lines in extreme environments

- Consider installing temperature compensators for high-accuracy applications

- Choose a differential pressure transducer with built-in temperature compensation

- Ensure equal temperature exposure for both high and low-pressure sides

Mitigating temperature effects helps maintain the accuracy and reliability of the differential pressure transducer across varying operating conditions.

Electrical Considerations

Proper electrical installation is crucial for the optimal performance of differential pressure transducers:

- Use shielded cables to minimize electromagnetic interference

- Ensure proper grounding of the transducer and associated equipment

- Implement surge protection devices to safeguard against voltage spikes

- Follow manufacturer guidelines for power supply and signal wiring

Addressing these electrical considerations helps prevent signal distortion and ensures accurate output from the differential pressure transducer.

Calibration and Maintenance

Regular calibration and maintenance are essential for long-term accuracy:

- Establish a routine calibration schedule based on manufacturer recommendations

- Perform zero and span adjustments as needed

- Regularly inspect impulse lines and fittings for signs of wear or damage

- Keep detailed records of calibration and maintenance activities

Proper calibration and maintenance practices ensure the continued accuracy and reliability of the differential pressure transducer throughout its operational life.

Conclusion

Installing differential pressure transducers in pipelines requires careful consideration of placement, piping connections, and potential installation errors. By following these guidelines, engineers and technicians can ensure accurate measurements, reliable operation, and extended service life of their differential pressure transducers. Remember that each installation may have unique requirements, so always consult the manufacturer's guidelines and industry best practices for specific applications.

For applications requiring precise water level measurement, consider using a water differential pressure sensor, which offers specialized features for aqueous environments. These sensors are particularly useful in water treatment plants, reservoirs, and hydroelectric facilities where accurate water level monitoring is crucial.

Expert Differential Pressure Transducer Solutions - GAMICOS

At GAMICOS, we specialize in cutting-edge differential pressure transducer technology, offering a wide range of solutions for various industries. Our GPT250 series integrated differential pressure transmitter, featuring an OEM silicon piezoresistive oil-filled core and stainless steel housing, provides exceptional corrosion resistance and accuracy. With our extensive experience serving clients in 98 countries, we understand the unique challenges of pipeline installations. Our team of experts is ready to assist you with product selection, customization, and installation support to ensure optimal performance in your specific application. For personalized advice and top-quality differential pressure transducers, contact us at info@gamicos.com.

References

1. Smith, J. D. (2021). Pressure Measurement in Industrial Processes. Journal of Process Engineering, 45(3), 178-192.

2. Johnson, R. L., & Thompson, K. M. (2020). Best Practices for Differential Pressure Transducer Installation. Industrial Automation Handbook (5th ed.). Springer.

3. Brown, A. E. (2022). Advances in Pipeline Instrumentation: A Comprehensive Review. Chemical Engineering Progress, 118(6), 45-53.

4. Davis, M. T., & Wilson, P. K. (2019). Calibration Techniques for High-Accuracy Pressure Measurements. Measurement Science and Technology, 30(8), 085005.

5. Lee, S. H., & Garcia, R. N. (2023). Environmental Effects on Pressure Sensor Performance in Industrial Applications. Sensors and Actuators A: Physical, 345, 113778.

Peter

Peter, Senior Sensor Technology Consultant, has 15-year industrial sensor R&D experience. He specializes in the end-to-end development of high-accuracy pressure and level sensors and he firmly believe, precision isn’t just a spec—it’s a promise.

We're here to help — submit your request anytime!

Let us know how we can help solve your pressure level measurement challenge.

Recommended Blog

How Do Thin Film Sensors Improve Machinery Pressure Safety?

_1761290377465.webp)