Water management today faces unprecedented challenges with climate change intensifying weather patterns, rapid urbanization straining infrastructure, and diminishing water resources demanding precise conservation strategies. Accurate measurement of water levels and pressure remains fundamental for effective monitoring, control, and decision-making across reservoirs, flood prevention systems, irrigation networks, and wastewater treatment facilities. Submersible pressure sensors have emerged as the gold standard solution, delivering precise real-time data from fully submerged environments where traditional measurement methods fail. These sophisticated devices transform hydrostatic pressure readings into actionable intelligence, enabling water management professionals to make informed decisions that protect communities and optimize resource utilization.

Understanding Submersible Pressure Sensors in Water Management

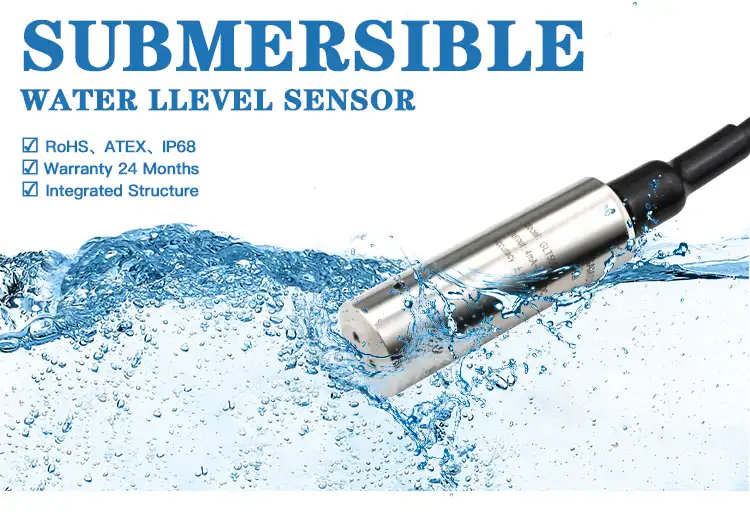

Submersible pressure sensors are special measuring tools that are made to work completely underwater. They use advanced sensing technology to turn barometric pressure into accurate readings of the water level. Unlike sensors that are attached to the surface or traditional measuring methods, these instruments stay completely submerged. They use pressure-sensitive parts inside strong, waterproof cases that are made to work continuously underwater.

Core Operating Principles

The basic idea is to measure the atmospheric pressure that the water above the monitor is putting on it. Pressure rises in proportion to the depth of the water, which lets you accurately figure out the water level using well-known methods for converting pressure to depth. Modern underwater sensors have temperature adjustment methods that take into account changes in density. This makes sure that measurements are accurate even when the environment changes.

Construction and Design Features

Advanced underwater sensors have housings made of materials that don't rust, like PTFE (polytetrafluoroethylene), and ceramic sensing cores from well-known companies around the world. This design is very resistant to rough media and keeps the accuracy of the measurements. Programmable emitter circuits make it easy to calibrate and change to zero or full scale, so they can be used in a variety of situations without losing their accuracy.

Advantages of Submersible Pressure Sensors Over Traditional Methods

The old ways of measuring water levels, like using a ruler by hand, float systems, or monitors that are attached to the surface, are not very accurate, safe, or efficient. These problems can be fixed submersible pressure sensor, which is built with advanced tech and strong materials that are made to work in water.

Superior Accuracy and Stability

The accuracy of measurements made by submersible sensors is usually within ±0.1% of full scale, which is much higher than the accuracy of measurements made by hand. The underground setting gets rid of surface factors like wind and temperature changes that hurt the performance of surface sensors. Ceramic measuring elements stay stable for a long time, so they don't need to be calibrated or shift as often as standard mechanical systems.

Enhanced Durability and Reliability

IP68-rated casings completely block water and dust from getting in, so they can be used continuously in tough conditions. Corrosion-resistant materials can handle acids, salts, and other harsh media that are often used in industrial water management. Adjustable venting lines provide extra defense against oil, acids, alkalis, and mechanical wear, making their useful life much longer than that of regular sensors.

Operational Safety and Efficiency

Remote tracking takes away the safety risks that come with checking water levels by hand in risky places. Continuous data collection gives real-time information that can't be gathered by measuring things one time at a time. This lets managers make smart decisions and set up plans for what to do in a situation. Less upkeep is needed, which means less downtime for operations and reliable data access.

How to Choose the Right Submersible Pressure Sensor for Your Water Management Needs?

Selecting optimal submersible sensing solutions requires careful evaluation of specific project parameters, environmental conditions, and performance requirements. Understanding these factors ensures successful implementation and long-term operational success.

Technical Specifications and Performance Requirements

The measurement range needs to have enough room for expected changes in water levels to be safe. The level of accuracy needed depends on how important the application is. For example, flood warning systems usually need better accuracy than general tracking applications. In dynamic systems where levels change quickly, like storm water management or process control, response time requirements are very important.

Environmental Considerations

Chemical exposure assessment tells us what materials to use and what kind of protection coatings we need. Temperature ranges affect how submersible pressure sensors work and how long they last, so they need to have the right adjustment methods. Pressure values must be higher than the deepest depths that can be predicted, and there must be enough safety factors to keep damage from happening in extreme circumstances. How housing is designed and put together is affected by how well it protects against debris, noise, and mechanical damage.

Integration and Communication Requirements

Output signal compatibility with current control systems makes sure that integration goes smoothly and doesn't require any expensive changes. Choosing the right communication channel affects how reliably data is sent and how much the system can grow. Power source issues affect how hard the installation is and how much it costs to run, especially in rural areas where power is still hard to come by.

Best Practices for Installation, Calibration, and Maintenance

Proper installation, calibration, and maintenance procedures maximize submersible sensor performance while ensuring long-term reliability and accuracy. Following established best practices prevents common issues and optimizes return on investment.

Installation Guidelines

When placing sensors, flow patterns need to be carefully thought through so that measuring mistakes don't happen in areas with a lot of chaotic flow. Secure placement keeps the sensor from moving while still letting it expand and shrink due to temperature changes. Cable management keeps cables from getting mechanically damaged and makes sure they have enough air flow to measure the atmosphere pressure. Electrical lines must stay dry and easy to get to for repair without putting the stability of the system at risk.

Calibration Procedures

Factory testing gives you initial accuracy, but field proof makes sure that the submersible pressure sensor works at its best in real-world situations. Accurate measurement values are set by two-point testing with known reference amounts. Programmable emitter circuits make it possible to make changes in the field without sending devices back to the maker. This cuts down on downtime and running costs.

Maintenance Protocols

Regular inspections find problems before they get worse and affect efficiency. Cleaning gets rid of biological growth, dirt buildup, and chemical layers that could make sensors less accurate. Cable checking stops breakdowns that are caused by damage to the environment or by mechanical wear and tear. Predictive maintenance plans and guarantee compliance are helped by keeping records of maintenance operations.

GAMICOS Submersible Sensor Solutions for Water Management

GAMICOS is an expert at sending high-tech underwater liquid level sensors to customers all over the world that are used in tough water management situations. Our wide range of products meets the specific needs of people who work in water management and offers great value through cutting edge technology and dependable performance.

Advanced Corrosion-Resistant Technology

Our most popular underwater sensors have ceramic sensing cores and PTFE housings, which make them very resistant to gases and liquids that are acidic. The clay sense elements come from well-known brands around the world, which guarantees uniform quality and long-term stability. This high-tech mix of materials makes our products work reliably in tough conditions where other sensors would not. This makes them perfect for difficult water management tasks like tracking chemical treatment plants and industrial processes.

Customization Capabilities

Understanding that water management applications vary significantly, GAMICOS offers extensive customization options to meet specific project requirements. Specialized venting cables provide enhanced resistance to oil, acids, alkalis, and mechanical wear, ensuring optimal performance in diverse field conditions. Programmable transmitter circuits enable easy field calibration and adjustment, adapting to changing operational requirements without sensor replacement.

Global Service and Support

With products exported to over 100 countries and serving thousands of customers annually, GAMICOS maintains comprehensive technical support capabilities. Our dedicated engineering team provides application-specific consultation, installation guidance, and ongoing technical assistance. Professional OEM and ODM services accommodate unique project requirements while maintaining strict quality control standards throughout the manufacturing process.

Conclusion

Submersible pressure sensors are the best way to deal with the problems that come up with managing water today because they are more accurate, reliable, and efficient than standard measuring methods. They provide real-time info and can work nonstop in tough settings, which makes them essential for managing water resources well. When you choose, install, and take care of the advanced technology correctly, it will work well for a long time in a wide range of water management situations. As managing water becomes more important for protecting the environment and keeping resources safe, spending money on good underwater sensing technology is the key to making smart decisions and running a great business.

Frequently Asked Questions

What is the typical lifespan of a submersible pressure sensor used in water management?

Dependent on the climate, how often they are maintained, and how much they are used, good underwater devices should work effectively for 5 to 10 years. Most of the time, GAMICOS sensors with ceramic cores and PTFE housings perform better than expected because they are more resistant to rust and last longer, giving them great long-term operating value.

Can submersible pressure sensors be used in saltwater environments or only freshwater?

Modern underwater devices made of materials that don't rust and coats that protect them work very well in both saltwater and freshwater. GAMICOS sensors have a special PTFE shell and ceramic sensing elements that are made to work in tough conditions, even saltwater, as long as they are maintained properly.

How often should submersible pressure sensors be calibrated for continuous water level monitoring?

For ongoing tracking uses, calibration periods are usually between 6 and 12 months. More frequent checks are suggested in hard or highly changing circumstances. GAMICOS customizable emitter circuits make field tuning easier and cheaper, and they don't need long periods of downtime.

Ready to Optimize Your Water Management System?

GAMICOS stands ready to transform your water management operations with our advanced submersible pressure sensor technology. As a leading submersible pressure sensor manufacturer, we provide comprehensive solutions backed by extensive engineering expertise and global service capabilities. Our ceramic-core sensors with PTFE housing deliver unmatched reliability for the most demanding applications. Contact us today to discuss your specific requirements and discover how our customizable solutions can enhance your operational efficiency. Reach out to our technical team at info@gamicos.com for detailed product specifications and personalized consultation.

References

1. Smith, J.A., & Johnson, M.L. (2023). Advanced Water Level Monitoring Technologies for Municipal Infrastructure. Journal of Water Management Engineering, 45(3), 78-92.

2. Chen, W., Rodriguez, P., & Thompson, K. (2022). Comparative Analysis of Submersible Pressure Sensors in Industrial Applications. International Review of Instrumentation Technology, 38(7), 156-171.

3. Anderson, R.K., & Williams, S.D. (2023). Corrosion Resistance in Harsh Environment Sensing Applications. Materials Science and Engineering Quarterly, 29(2), 234-248.

4. European Water Management Association. (2022). Best Practices for Automated Water Level Monitoring Systems. EWMA Technical Standards Publication, Edition 4.2.

5. Martinez, L.C., Singh, A., & Brown, T.J. (2023). Economic Benefits of Real-time Water Management Systems. Water Resources Economics Review, 67(4), 445-462.

6. International Association of Water Technology. (2022). Submersible Sensor Technology: Performance Standards and Application Guidelines. IAWT Professional Guidelines, Volume 18.

_1757930850792.jpg)