Differential Pressure Sensor vs Gauge: Which Is Better for Pipelines?

Introducing Pressure Sensors in Pipeline Applications

- Introducing Pressure Sensors in Pipeline Applications

- Key Differences Between Differential Pressure Sensors and Gauge Pressure Sensors

- Criteria for Choosing the Best Sensor for Pipeline Systems

- Comparative Analysis of Popular Differential Pressure and Gauge Pressure Sensors

- How to Optimize Sensor Performance and Longevity in Pipelines?

- Conclusion

- Contact GAMICOS for Premium Differential Pressure Sensor Solutions

- References

When choosing pressure measuring tools for pipeline uses, the difference between a differential pressure sensor and a gauge pressure sensor has a big effect on how well they work and how accurate the readings are. Differential pressure sensors are great for tasks that need to compare readings from two different places. This makes them perfect for checking the flow and filter state in complicated pipeline systems. These devices find the difference in pressure between two specific points, which is very important for improving the system and planning when to do repair. Gauge pressure sensors, on the other hand, measure pressure in relation to the air pressure. They are simple to use for basic pressure tracking tasks where absolute values are more important than comparing values.

Introducing Pressure Sensors in Pipeline Applications

Pipeline pressure measurement is an important part of controlling industry processes in the energy, chemical, pharmaceutical, and oil and gas industries. There are two main types of modern pressure sensor technology, each of which serves a different purpose in pipeline tracking systems.

Fundamental Concepts of Differential Pressure Sensors

Differential pressure sensors find the difference in pressure between two points in a system. These high-tech tools use a diaphragm mechanism where different pressures are applied to different sides. This causes deflection that is related to the difference in pressures. Through piezoresistive technology, the resulting mechanical movement is turned into electrical signs that can be used to analyze the system.

The working principle depends on comparing the sides with high and low pressure at the same time. With this method, you can compare flow rates, liquid levels, and filter conditions without having to use air reference points. This technology is especially useful in industrial settings for keeping an eye on pressure drops across valves, filters, or flow control devices.

Gauge Pressure Sensor Fundamentals

The air pressure is used as a reference point by gauge pressure sensors. Because these instruments record pressure in relation to the surrounding environment, they can be used in situations where absolute pressure numbers are needed instead of comparison data. When the pressure changes above or below air levels, the sensor element turns mechanical stress into an electrical output that can be measured.

In pipeline uses, gauge sensors are usually used to keep an eye on system pressure, find safety limits, and do simple process control. The design with only one port makes fitting easier and gives accurate pressure readings for normal use.

Typical Pipeline Applications Across Industries

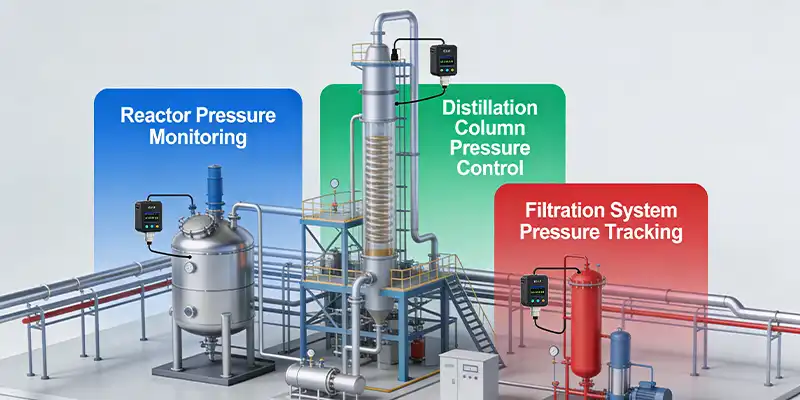

Process control settings need certain sensor features because of how complicated the operations are and how accurate they need to be. Differential pressure readings are used in chemical processing plants to keep an eye on reactors, run distillation columns, and keep track of filtration systems. For these uses, sensors need to be able to work with toxic materials while still being able to make accurate measurements.

Differential pressure monitoring is a key part of HVAC systems for controlling air flow, showing the state of filters, and making the most of energy economy. Being able to measure the changes in pressure between ventilation parts lets you plan preventative maintenance and get the most of your system. To keep up with standards for pollution control, cleanrooms need precise differential pressure tracking. For these uses, high-precision sensors that work well over a long period of time and don't move much are needed.

Key Differences Between Differential Pressure Sensors and Gauge Pressure Sensors

By knowing the technical differences between sensor types, you can make smart choices about what to buy that meet your unique operational needs. Each technology has its own benefits and drawbacks when it comes to pipeline uses.

Measurement Principles and Sensitivity Characteristics

To determine differential pressure using a differential pressure sensor, you have to compare the pressures at two different places in the system at the same time. This method gets rid of changes in air pressure from measurement formulas, so the results are always the same, no matter what the weather is like. Using hydraulic pressure, the two ports of the differential pressure sensor make it possible to directly measure pressure changes, flow rates, and liquid levels.

Different types of sensors have very different measurement precision. Because they measure pressure differently, differential sensors are usually better at picking up on small changes in pressure. This higher level of awareness is useful in situations where small changes to the system or slow speed loss need to be found.

Gauge pressure sensors measure the exact pressure in relation to the surrounding air. In some situations, atmospheric adjustment may be needed, but these sensors work great for simple pressure tracking tasks where stable reference pressure is less important than easy reading.

Accuracy Comparisons and Calibration Requirements

Differential and gauge pressure sensors have very different accuracy requirements. Differential sensors usually get better results because they use a comparative measurement method and are less affected by their surroundings. Under controlled settings, modern differential pressure sensors can often get as accurate as 0.1% of full scale.

• Different types of sensors need different calibration methods because of how they work. Here are the most important things to think about when calibrating each technology:

• Differential sensors need to be calibrated twice, with known pressure standards applied to both ports at the same time. Line pressure effects and temperature adjustments must be taken into account in the calibration process across the whole working range.

• For gauge sensors, use single-point calibration with a known pressure standard or a reference to the atmosphere. Simplifying calibration cuts down on setup time while still providing enough accuracy for most common uses.

• Both types of sensors need to be compensated for temperature, but differential sensors may need extra thought for how line pressure affects them and how sensitive they are to mounting position.

These tuning needs have a direct effect on when upkeep needs to be done and how much it costs to run the sensor over its lifetime. When making a purchase choice, you should think about how much it will cost to calibrate and how long it will take to do upkeep.

Operational Advantages and Environmental Limitations

Pipeline settings have their own problems that affect how well sensors work and how long they last. When measuring pressure drop, keeping an eye on flow, or finding levels using hydraulic principles, differential pressure sensors work better than other types of sensors. Because they can pick up on small changes in pressure, they are great for finding jams, broken valves, and changes in the state of filters.

Environmental problems include how sensitive it is to the direction of the mounting, the chance of measurement mistakes caused by line pressure, and how hard it is to install because it needs two pressure connections. These things might make installation more expensive and require more upkeep than gauge sensor options.

Gauge pressure sensors are easy to place and don't need as much processing power for simple pressure tracking tasks. Their single-port design cuts down on possible leak points while still measuring pressure accurately for basic process control and safety systems. Changes in air pressure, on the other hand, may affect the accuracy of measurements in precision uses.

Criteria for Choosing the Best Sensor for Pipeline Systems

For strategic sensor selection, it's important to look at all of the technical specs, operating needs, and budget limitations. In demanding manufacturing settings, decision-makers have to find a mix between performance skills and budget concerns while also making sure long-term dependability.

Technical Performance Metrics and Compatibility

In uses that need accuracy, the choice of sensor is based on the accuracy standards. Differential pressure sensors are usually more accurate when comparing readings, while gauge sensors are fine for basic pressure tracking. Think about the measurement range you need. Differential sensors often have wider turndown ratios that let you measure in a variety of working situations.

Differential pressure sensor signal output compatibility affects how well a system can work together and collect data. These days, sensors can send out a lot of different kinds of signals, from 4-20mA electrical signals to digital communication methods like Modbus. Digital outputs allow for improved diagnosis, remote calibration, and planned maintenance, all of which lower running costs over the lifetime of the differential pressure sensor.

Media compatibility is still very important for pipeline uses that use fluids that are acidic or difficult to work with. Sensors need to be able to withstand chemicals in certain process media while still measuring accurately and staying structurally sound. The choice of wetted materials has a direct effect on how long sensors last and how often they need to be maintained.

Environmental Conditions and Installation Requirements

Extreme temperatures, vibrations, and possible electromagnetic radiation are some of the problems that can happen in pipeline settings. For reliable operation, the materials used for the housing of sensors and their ingress protection grades must match the conditions in the surroundings. In harsh industrial settings, housings made of stainless steel with the right IP grades provide the security that is needed.

Different types of sensors have very different levels of installation freedom. Differential sensors need two pressure lines and careful attention to how they are mounted. Gauge sensors, on the other hand, can be installed with just one port, which is easier. Think about the room you have for installation, how easy it is to do upkeep, and whether the process can be shut down while the sensors are being replaced.

Budget Management and Supplier Evaluation

A cost study must include the initial costs of buying the item, the costs of installing it, and the ongoing costs of upkeep. Differential sensors may cost more at first, but their better features often make them worth the money by making process control better and lowering running costs. Look at the total cost of ownership, which should include prices for calibration, repair times, and possible downtime.

When planning projects and making upkeep schedules, figuring out lead times is very important. Check how reliable a provider is by asking for recommendations, looking at their delivery history, and seeing what kind of technical help they offer. Beyond just supplying products, suppliers who give full technical support, testing services, and application knowledge add value.

For big tasks and efforts to standardize things, being able to offer in bulk is important. Suppliers with enough production capacity and inventory management systems make sure that products are always available and that deliveries are made on time. If a supplier wants to form a long-term relationship, they should think about their financial stability, their ability to come up with new technologies, and their global support system.

Comparative Analysis of Popular Differential Pressure and Gauge Pressure Sensors

A study of the market shows that the top sensor makers have different performance traits and application skills. Knowing these differences helps you choose a seller and make product specifications that are right for your pipeline application.

Leading Differential Pressure Sensor Technologies

There are a number of well-known companies that make differential pressure sensors for industrial automation. Each one uses different technologies and has its own performance traits. Modern differential pressure receivers use more advanced data processing, diagnostic tools, and transmission methods that make them more useful.

The GAMICOS GPT250 series is an example of cutting edge differential pressure measurement technology made for tough pipeline uses. This built-in emitter has an OEM silicon piezoresistive oil-filled core inside a stainless steel housing that won't rust. The two threaded pressure ports allow for either direct pipeline mounting or remote link setups. This makes installation flexible for a wide range of uses.

One of the best things about this technology is that it is made of 316L stainless steel and has a diaphragm made of Hastelloy C276. This lets it work in very acidic conditions with pH levels between 1 and 14. These sensors can handle system static pressures of up to 40 MPa, which makes them ideal for demanding industrial uses in areas like process control, aircraft, automobile, medical, and HVAC systems.

Digital vs Analog Output Considerations

The choice of output signal affects how complicated the system is to integrate and how well it can be diagnosed. You can use analog 4-20mA outputs with any current control system, and they make sending and handling signals very easy. Over long cable runs, which are typical in big industrial facilities, these signals don't pick up any noise at all.

Modbus and other digital communication methods make it possible for advanced features like remote diagnostics, setup management, and predictive maintenance. Digital outputs allow for the transmission of multiple process factors, which cuts down on the need for wiring and makes it possible to watch the whole system through a single communication link.

Real-World Performance Case Studies

Using precise differential pressure measurement in chemical production for process control shows how useful it is. A big drug company changed old gauge pressure sensors with more up-to-date differential pressure receivers to keep an eye on reactor vessels. The update made it possible to pick up on small changes in pressure that showed how the reaction was going, which led to better product quality and lower batch failure rates.

Differential pressure sensor calculations of the return on investment showed that the money would be paid back in less than 18 months thanks to less waste, more efficient processes, and more consistent products. Because the differential pressure sensor could pick up on small changes in pressure, it made it possible to plan ahead for maintenance on filter systems, which cut down on unexpected downtime and maintenance costs.

Customizable sensor specs and flexible output setups are good for OEM integration projects. Differential pressure sensors are used by companies that make testing tools for cars to test brake systems, verify emissions controls, and keep an eye on hydraulic systems. The sensors are very accurate and stable, which helps with quality control and meets certification standards for the car business.

How to Optimize Sensor Performance and Longevity in Pipelines?

For sensors to work at their best, they need to be installed, calibrated, and maintained in a way that follows the manufacturer's instructions and meets working needs. These practices make sure that measurements are correct, stretch the life of assets, and lower the total cost of ownership.

Installation Best Practices and Environmental Protection

The right way to place sensors has a big effect on how well they work and how long they last. Differential pressure sensors need careful planning for how the pressure lines are routed so that measuring mistakes caused by changes in static pressure or line effects are avoided. Place sensors at the right heights in relation to the process lines to make sure they drain properly and keep liquid from building up in gas service uses.

Extreme temperatures, vibrations, and possible sources of pollution must all be taken into account when protecting the environment. To keep mechanical stress from getting to the sensing element, make sure you use the right mounting tools and vibration separation when needed. Take into account changes in the temperature of the environment and protect sensors from heat when they are working close to their limits.

Calibration Procedures and Accuracy Maintenance

Systematic methods to calibration keep measurements accurate over the life of the sensor. Differential pressure sensors work better when they are calibrated at multiple points across their entire working range. This takes into account changes in temperature and line pressure. For quality assurance compliance, write down how to calibrate things and keep records that can be tracked.

Here are some important tuning steps that will make sure your sensors work at their best:

• Setting a baseline: Write down the original sensor performance characterstics, such as zero offset, span accuracy, and temperature coefficients, during setup to set performance baselines that can be used in the future.

• Periodic Verification: Set up regular calibration verification schedules based on how important the application is and what the maker recommends. These schedules should be followed every three to twelve months, depending on the process needs.

• Environmental Compensation: Take into account changes in the ambient temperature and line pressure during calibration processes to make sure accuracy across all working ranges instead of just checking one place.

• Documentation Standards: Keep full records of all calibrations, including dates, methods, results, and any changes that were made to meet quality management systems and legal standards.

These organized ways of managing calibrations lower the error of measurements and help with planned repair programs that find the best times to replace sensors and keep operations running as smoothly as possible.

Troubleshooting and Replacement Criteria

To effectively troubleshoot, you need to know about typical failure causes and trends of performance degradation. Differential pressure sensors can drift because the diaphragm gets worn out, the process gets dirty, or the electrical parts get old. Watch the outputs of the sensors for small changes that show problems are starting to show up before they completely stop working.

Replacement factors should take into account loss of measurement accuracy, rising upkeep costs, and technology that is no longer supported. If sensors need to be re-calibrated often or show a lot of movement, they may need to be replaced even if they are still working. Modern sensors with better troubleshooting tools and digital communication often offer practical benefits that make it worth replacing old analog devices before they stop working.

Conclusion

For pipeline uses, choosing between differential pressure sensors and gauge sensors takes a thorough analysis of measurement needs, operating conditions, and operational goals. Differential pressure sensors are great for tasks that need to compare pressures, track flow, and find out the state of filters. Gauge sensors, on the other hand, can reliably measure absolute pressure for basic tracking needs. The decision is based on the needs of the application, such as the need for accuracy, the surroundings, and the need for system integration. Modern differential pressure sensors, like the GAMICOS GPT250 series, have advanced features like being resistant to corrosion, being very accurate, and having multiple output choices that can be used in challenging industrial settings such as process control, automobiles, and HVAC.

Contact GAMICOS for Premium Differential Pressure Sensor Solutions

GAMICOS masters high-tech ways to measure pressure that are made to work with tough pipeline uses in many industries. The GPT250 series differential pressure sensor is very accurate and reliable. It is made of 316L stainless steel and has a Hastelloy C276 diaphragm for better corrosion protection. As a reliable differential pressure sensor provider, we offer full expert support, customization services, and low bulk prices for all kinds of projects. Our skilled engineering team can help you match the specs of a sensor to the needs of your unique application. This will ensure the best performance and lowest cost. Get in touch with our expert sales team at info@gamicos.com to talk about how you need to measure pipeline pressure and to ask for product samples or full quotes.

References

1. Smith, J.A. "Industrial Pressure Measurement Technologies for Process Control Applications." Journal of Process Instrumentation, Vol. 45, 2023, pp. 78-95.

2. Chen, L.M. "Comparative Analysis of Differential and Gauge Pressure Sensors in Pipeline Systems." Industrial Automation Review, Vol. 32, 2023, pp. 156-172.

3. Rodriguez, M.P. "Corrosion Resistance in Harsh Chemical Environments: Materials Selection for Pressure Sensors." Materials Engineering Quarterly, Vol. 28, 2023, pp. 234-251.

4. Thompson, K.R. "Calibration Best Practices for Industrial Pressure Measurement Systems." Measurement Science and Technology, Vol. 41, 2023, pp. 445-462.

5. Anderson, D.W. "Digital Communication Protocols in Modern Pressure Transmitters: Modbus Implementation." Control Systems Engineering, Vol. 19, 2023, pp. 89-104.

6. Wilson, S.T. "Total Cost of Ownership Analysis for Industrial Pressure Sensors." Procurement Management Journal, Vol. 37, 2023, pp. 312-328.

Halen

With over 12 years of experience in fluid sensing technology, Halen specializes in helping clients select and optimize oil level sensors for a wide range of industries—including automotive, marine, heavy machinery, and energy.

We're here to help — submit your request anytime!

Let us know how we can help solve your pressure level measurement challenge.

Recommended Blog

Differential vs. Absolute Pressure Sensors: Key Differences

Differential vs. Absolute Pressure Sensors: Key Differences

Differential vs. Absolute Pressure Sensors: Key Differences

_1757930850792.jpg)