Submersible sensors with IP68/IP69K ratings, ceramic diaphragm designs, and titanium alloy housings are some of the best waterproof pressure transducers for harsh settings. These ruggedized devices can measure pressure accurately in harsh situations, such as underwater, chemical processing, and marine settings. A good waterproof pressure transducer has electronics that are sealed and materials that don't rust, so it works reliably when other instruments don't.

Critical Selection Criteria for Harsh Environment Applications

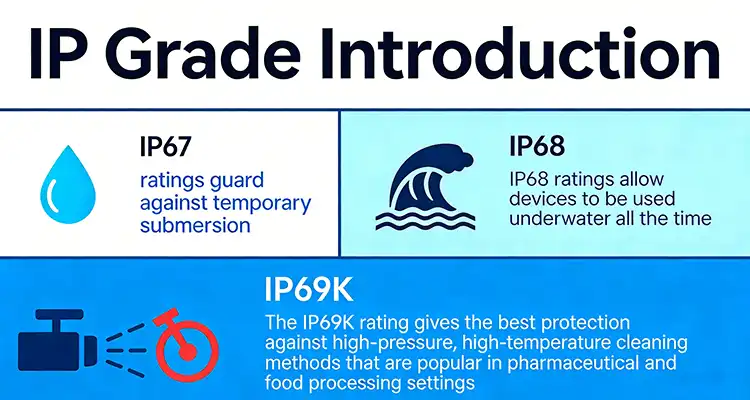

To choose waterproof pressure monitors that work well, you need to look at more than just how waterproof they are. The most important things to think about are the ingress protection ratings, the compatibility of the materials, the stability of the temperature, and the signal integrity in bad circumstances. The ingress protection scores tell you how resistant a device is to solids and liquids getting in. IP67 ratings guard against temporary submersion, while IP68 ratings allow devices to be used underwater all the time.

The IP69K rating gives the best protection against high-pressure, high-temperature cleaning methods that are popular in pharmaceutical and food processing settings. The choice of material affects how long something will last and how well it works with chemicals. Stainless steel housings don't rust in most situations, but they can break down in chloride conditions. Titanium metals are better at resisting corrosion, but they cost more.

For aggressive media uses, ceramic diaphragms are very stable and work well with chemicals. Across all working ranges, measurement accuracy is affected by how stable the temperature is. From -40°C to +125°C, good waterproof pressure transducer gauges keep their readings. Compensation methods keep thermal drift to a minimum, and special designs can handle changes in temperature that are very high or very low without breaking down.

GAMICOS Submersible Pressure Transmitter Series

The GAMICOS submersible pressure sensor line is a high-tech, waterproof pressure measuring system made to work continuously underwater. These devices are made of 316L stainless steel and have special cable entry designs that get rid of the places where moisture can get in that are common in competing goods. A piezoresistive silicon sensor is built into each unit and is covered by a ceramic isolation diaphragm. This design keeps the media from touching sensitive electronics and keeps the accuracy and long-term stability at a high level.

Over the course of a year, the transmitters have very little drift and are accurate to within 0.25% FS across their working temperature range. Multiple process links and cable lengths of up to 100 meters give you a lot of installation options. The strong polyurethane wire can handle being bent over and over and being exposed to chemicals. Lightning safety circuits keep electrical surges that happen a lot in outdoor installations from damaging equipment.

Groundwater tracking, tank level measurement, and marine depth sensing are all uses for this technology. The devices work reliably in fresh water, salt water, and some liquids that are slightly corrosive. With temperature correction, readings are always correct from -10°C to +80°C, without having to be recalibrated. Specialized materials for aggressive media, explosion-proof housings for dangerous areas, and digital communication protocols are some of the customization choices. GAMICOS offers full documentation packages that meet the needs of foreign certification, such as CE marking and ATEX approval.

Industrial Grade Waterproof Pressure Controllers

Pressure devices that are both high-performance and waterproof combine measuring and controlling functions in tough cases that are good for automated systems. The housings of these waterproof pressure transducers are marked IP65/IP67 and have clear polycarbonate windows that let you see the display while protecting the internal parts from the environment. More advanced models have two alarm outlets, the ability to send analog signals again, and the ability to communicate digitally.

Process media temperatures can go up to +150°C, and the controls can keep measurement accuracy within ±0.5% of full scale. Wetted parts made of stainless steel ensure that they can handle most industrial fluids chemically. Programming flexibility lets you change the alarm setpoints, output scaling, and damping factors using controls on the front panel or communication links from afar. When the power goes out, the battery backup keeps the settings, and the non-volatile memory keeps the setup from being lost. Panel installation, pipe mounting, and wall mounting configurations are all possible ways to place something.

Quick-disconnect electrical links make it easier to install and fix things. Self-diagnostic features find problems with sensors and transmission problems quickly, cutting down on the time needed to fix them. These controls work great in situations where local indication and remote monitoring are needed. In most installations, environmental safety and control are both very important. This includes pump control systems, filter monitoring, and pressure relief valve supervision.

Hygienic Waterproof Pressure Sensors for Food Processing

When working with food and drinks, you need waterproof pressure tools that can handle being cleaned a lot and still meet strict hygiene standards. Specialized designs get rid of any cracks where bacteria could grow and protect against high-pressure washing processes completely. Hygienic sensors have surfaces made of polished stainless steel and tri-clamp links that meet 3-A sanitary standards. When the diaphragms are flush-mounted, there are no empty areas that could hold contaminants.

During the CIP (Clean-in-Place) and SIP (Steam-in-Place) processes, moisture can't get in because of special sealing methods. Temperature resistance goes up to +150°C, so that steam sterilization processes can be done without losing accuracy. Standard cleaners, such as sodium hydroxide, nitric acid, and chlorine-based sanitizers, are chemically compatible. Materials that have been cleared by the FDA ensure that food contact rules are followed. Standard 4-20mA signals, HART communication, and digital protocols for integration with modern process control systems are all output choices.

Stable calibration cuts down on drift between cleaning cycles, which lowers the need for upkeep and ensures that the quality of the product stays the same. Pressure tracking is used in many situations, such as when processing dairy, making drinks, or making medicines, where both measurement accuracy and cleanliness are very important. For long production runs, the sensors work reliably, and they also help with quick changeover processes.

Regional Market Analysis and Compliance Requirements

Demand for waterproof pressure transducer monitoring devices varies a lot from one part of the world to another because of differences in industries, environments, and rules. Knowing these things about the area helps you choose the best products and make sure they meet local standards. In the Americas, oil and gas applications are very important. Subsea pressure measurement and pipeline tracking are two main uses for strong, waterproof pressure devices.

NACE corrosion standards affect the choice of material, while API specs spell out what the performance needs to be. Extremely cold weather affects systems in Canada, which need special temperature compensation. European markets emphasized protecting the earth and using energy efficiently. ATEX guidelines require designs that can't explode for use in dangerous areas. Safety guidelines and EMC compatibility are part of the CE marking requirements.

Nordic countries need better performance in cold weather, while Mediterranean areas focus on stability at high temperatures. Asian markets are growing quickly when it comes to using chemicals to make things. Japanese buyers expect a high level of accuracy and dependability. Korean shipbuilding businesses need waterproof pressure systems that are made for marine use. The warm weather in Southeast Asia makes corrosion resistance and humidity protection difficult.

Implementation Best Practices and Installation Considerations

To successfully use waterproof pressure measurement devices, you need to pay close attention to the details of the installation and the environment. Long-term dependability and measurement accuracy are directly affected by how well the equipment is mounted, how the cables are managed, and how the electrical connections are made. As much as sensor quality, the choice of cable affects how well the system works. Polyurethane jackets are very resistant to wear and are compatible with chemicals.

At connection places, cable fatigue can be avoided with the right pressure relief. For submersible uses, you need special cable entry seals that can handle being submerged in water all the time. When working in harsh conditions, electrical links need extra care. Terminals are kept dry from getting wet by sealed junction boxes. When you ground something properly, electrical noise and lightning damage are less likely to happen. Surge safety devices keep expensive instruments safe from short-term overvoltages.

When you do the calibration, you should take into account things like mounting stress, changes in temperature, and sound exposure. After placement, accuracy is checked in the field using portable calibrators. Maintenance plans that are followed regularly keep services running smoothly and extend their lives. Different industries and uses have different documentation needs. Full installation records help with fixing problems and following the rules. Maintenance logs keep track of trends in performance and find possible problems before they happen.

Conclusion

Waterproof pressure transducer measurement technology continues evolving toward enhanced connectivity and predictive maintenance capabilities. IoT integration enables remote monitoring and data analytics for improved system reliability. Wireless communication protocols reduce installation costs while expanding deployment possibilities. Advanced materials development improves chemical compatibility and extends service life in increasingly demanding applications across global markets.

Frequently Asked Questions

What IP rating do I need for underwater pressure measurement applications?

IP68 rating provides continuous submersion protection for underwater applications. This rating ensures the waterproof pressure transducer can operate reliably when completely immersed in water for extended periods. Temporary submersion applications may use IP67-rated devices, but permanent underwater installations require IP68 certification for long-term reliability.

How do I select materials for chemical processing applications?

Material selection depends on your specific chemical media and operating conditions. Stainless steel 316L handles most general applications, while Hastelloy or titanium may be required for aggressive chemicals. Consult chemical compatibility charts and consider factors like temperature, concentration, and exposure duration when selecting wetted materials for your waterproof pressure sensor.

Can waterproof pressure transmitters handle high-vibration environments?

Quality waterproof pressure transmitters incorporate vibration-resistant designs, including shock-mounted sensors and robust housing construction. Look for devices tested to IEC 60068 vibration standards. Proper mounting techniques and vibration isolation may be required for extreme vibration applications to ensure accurate pressure measurement.

Partner with GAMICOS for Your Waterproof Pressure Transducer Requirements

Selecting the optimal waterproof pressure measurement solution requires expertise in application analysis, product selection, and system integration. GAMICOS combines decades of sensor manufacturing experience with comprehensive engineering support to deliver customized solutions for your most challenging applications.

Our waterproof pressure transducer manufacturer capabilities include custom sensor designs, specialized materials selection, and complete system integration services. We understand the unique requirements of harsh environment applications and provide products that exceed industry standards for durability and performance.

Technical support extends throughout the product lifecycle from initial specification through installation and ongoing maintenance. Our engineering team assists with sensor selection, mounting recommendations, and troubleshooting to ensure optimal system performance.

Quality assurance programs include comprehensive testing protocols and international certifications. Each device undergoes rigorous environmental testing to verify waterproof performance and measurement accuracy under specified operating conditions. Ready to discuss your waterproof pressure measurement requirements? Contact our technical specialists to explore customized solutions for your application. Reach out to us at info@gamicos.com for detailed product information and application engineering support.

_1757930850792.jpg)