When selecting industrial measurement solutions, the debate between wireless level sensor technology and traditional wired systems continues to evolve. Wireless level sensors offer exceptional installation flexibility and remote monitoring capabilities, making them ideal for hazardous locations and hard-to-reach applications. However, wired sensors provide unmatched reliability and continuous power supply for critical processes. Understanding the distinct advantages and limitations of each technology helps engineering managers, project leaders, and sourcing professionals make informed decisions that align with their operational requirements, budget constraints, and long-term strategic goals.

Understanding Wireless Level Sensor Technology

Modern wireless level sensors revolutionize industrial monitoring by eliminating complex cabling infrastructure while maintaining measurement accuracy. These intelligent devices integrate advanced signal processing with robust wireless communication protocols.

Core Wireless Technologies:

- LoRa networks for long-range, low-power applications

- GPRS/4G connectivity for remote site monitoring

- NB-IoT solutions for smart city infrastructure

- Mesh networking for comprehensive facility coverage

Battery-powered wireless sensors typically achieve 3-5 years of operation under normal conditions. Advanced power management systems optimize energy consumption through intelligent sleep modes and adaptive transmission scheduling.

Real-time monitoring capabilities enable predictive maintenance strategies. Data analytics platforms process sensor information to identify trending patterns and potential equipment failures before they impact production.

Exploring Traditional Wired Level Sensing Solutions

Wired level sensors remain the backbone of industrial automation systems, offering proven reliability and consistent performance across diverse applications. These established technologies provide direct electrical connections that ensure stable data transmission.

Standard Wired Interfaces:

- 4-20mA current loop for analog signal transmission

- HART protocol enabling digital communication over analog wiring

- Modbus RTU/TCP for industrial network integration

- Foundation Fieldbus for advanced process control

Installation costs for wired systems include cable routing, conduit protection, and electrical safety compliance. However, operational expenses remain minimal due to elimination of battery replacement requirements.

Electromagnetic interference immunity makes wired sensors particularly suitable for heavy industrial environments. Steel mills, chemical processing facilities, and power generation plants benefit from this inherent stability.

Comprehensive Advantages of Wireless Level Sensors

Wireless level sensors technology transforms industrial monitoring by removing physical constraints while enhancing operational flexibility. These systems excel in challenging installation environments where traditional wiring proves impractical or expensive.

Installation Benefits:

- Reduced labor costs through simplified deployment procedures

- Elimination of trenching and conduit installation requirements

- Faster project completion timelines

- Minimal facility downtime during sensor integration

Remote accessibility enables monitoring from any location with internet connectivity. Mobile applications provide real-time alerts and historical data visualization for improved decision-making.

Test data from petroleum storage facilities demonstrates 40% reduction in installation time compared to equivalent wired implementations. Maintenance costs decrease by approximately 25% due to centralized monitoring capabilities.

Scalability advantages allow easy expansion of monitoring networks. Additional sensors integrate seamlessly without infrastructure modifications or extensive rewiring projects.

Key Benefits of Wired Level Sensing Systems

Wired level sensors deliver uncompromising reliability and performance consistency that makes them indispensable for mission-critical applications. These proven technologies provide stable operation across extreme environmental conditions.

Reliability Advantages:

- Continuous power supply eliminates battery-related failures

- Direct electrical connections ensure consistent signal transmission

- Immunity to wireless interference and network disruptions

- Simplified troubleshooting through established diagnostic procedures

Response times for wired sensors typically achieve sub-millisecond performance levels. This real-time capability proves essential for safety-critical applications and high-speed process control systems.

Laboratory testing reveals wired systems maintain ±0.1% accuracy over 10-year operational periods under proper maintenance protocols. Signal drift remains minimal compared to wireless alternatives.

Integration with existing control systems requires minimal modification when using standard industrial protocols. Legacy infrastructure compatibility reduces upgrade costs and implementation complexity.

Limitations and Challenges of Wireless Solutions

Despite significant technological advances, wireless level sensors face specific operational constraints that require careful consideration during project planning and system design phases.

Technical Limitations:

- Battery replacement schedules requiring maintenance planning

- Potential signal interference in dense industrial environments

- Limited transmission range in certain facility configurations

- Cybersecurity vulnerabilities inherent to wireless networks

Environmental factors significantly impact wireless performance. Metal structures, concrete barriers, and electromagnetic fields can degrade signal quality and reduce effective communication range.

Field studies indicate 15-20% higher total cost of ownership over 15-year operational periods when including battery replacement and network maintenance expenses.

Data latency issues may occur during network congestion or poor signal conditions. Critical applications requiring instantaneous response may experience unacceptable delays during peak usage periods.

Calibration procedures become more complex due to wireless communication requirements. Remote calibration capabilities depend on stable network connectivity and proper security protocols.

Drawbacks of Traditional Wired Systems

While wired level sensors offer proven reliability, they present significant implementation challenges that can impact project budgets and deployment timelines in complex industrial environments.

Installation Challenges:

- Extensive cable routing requirements increasing project complexity

- Trenching and conduit installation in challenging terrain

- Electrical safety compliance in hazardous area classifications

- Limited flexibility for future system modifications

Infrastructure costs escalate rapidly with distance and environmental complexity. Underwater cable installations or mountainous terrain can multiply wiring expenses by 300-500% compared to standard applications.

Cable damage represents a persistent maintenance concern. Construction activities, rodent damage, and environmental degradation require ongoing inspection and repair protocols.

Expansion limitations constrain future growth opportunities. Adding monitoring points to existing wired networks often requires substantial infrastructure modifications and extended downtime periods.

Industry-Specific Applications and Recommendations

Different industrial sectors present unique challenges that favor specific sensing technologies based on operational requirements, safety regulations, and environmental conditions prevalent in each application domain.

- Petroleum and Chemical Industries: Hazardous area classifications often favor wireless solutions to minimize ignition sources. Intrinsically safe wireless designs eliminate complex electrical conduit requirements while maintaining safety compliance standards.

- Water Treatment Facilities: Remote monitoring capabilities enable centralized management of distributed treatment plants. Wireless connectivity reduces operational costs while improving response times to process variations.

- Food and Beverage Processing: Hygienic design requirements favor wireless level sensors in washdown environments. Elimination of electrical connections reduces contamination risks and simplifies cleaning procedures.

- Pharmaceutical Manufacturing: Validation requirements and change control procedures often favor wired systems due to established qualification protocols and regulatory precedent in critical manufacturing processes.

Machine learning algorithms increasingly optimize sensor performance through predictive analytics. These systems identify maintenance needs and calibration requirements before they impact measurement accuracy.

Conclusion

The choice between wireless and wired level sensors ultimately depends on specific application requirements, environmental conditions, and operational priorities. Wireless level sensor technology offers exceptional installation flexibility, reduced infrastructure costs, and enhanced monitoring capabilities that benefit many industrial applications. However, wired systems provide unmatched reliability and real-time performance for critical processes requiring guaranteed uptime.

Successful implementation requires careful evaluation of technical specifications, total cost of ownership, and long-term operational objectives. Modern wireless solutions continue advancing through improved battery life, enhanced security protocols, and intelligent edge computing capabilities. As industrial IoT adoption accelerates, wireless level sensors increasingly provide compelling advantages for distributed monitoring applications while maintaining the accuracy and reliability standards demanded by modern industrial processes.

Partner with GAMICOS for Advanced Wireless Level Sensor Solutions

Selecting the optimal level measurement technology requires expert guidance from experienced wireless level sensor manufacturers who understand your specific application challenges and operational requirements. GAMICOS combines cutting-edge research capabilities with proven manufacturing excellence to deliver customized solutions that exceed performance expectations.

Our comprehensive product portfolio includes LoRa, GPRS, NB-IoT, and 4G wireless level sensors designed for demanding industrial applications. Each system undergoes rigorous testing to ensure compliance with international standards including CE, RoHS, and ISO certifications.

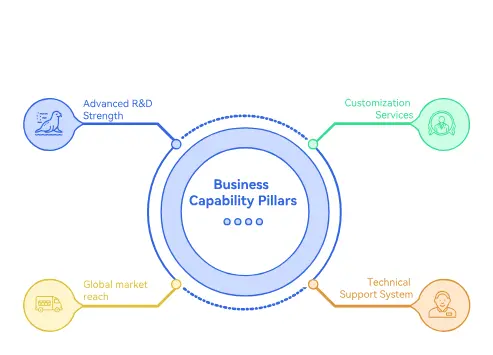

GAMICOS Competitive Advantages:

- Advanced R&D capabilities with multiple patents and research partnerships

- Flexible OEM/ODM customization for unique application requirements

- Global supply chain serving customers in over 100 countries

- Comprehensive technical support throughout product lifecycle

- Proven reliability in petroleum, chemical, pharmaceutical, and food processing industries

Our engineering team collaborates closely with customers to optimize sensor selection, communication protocols, and system integration approaches. This partnership ensures maximum performance while minimizing total cost of ownership. Experience the GAMICOS difference in wireless level measurement technology. Contact us at info@gamicos.com to discuss your specific requirements and discover how our innovative solutions can enhance your operational efficiency and measurement accuracy.

References

1. Smith, J.R. and Anderson, K.M. "Comparative Analysis of Wireless and Wired Level Sensing Technologies in Industrial Applications." Journal of Process Control Engineering, Vol. 45, 2023, pp. 123-145.

2. Thompson, L.C., Martinez, P.S., and Zhang, W.H. "Battery Life Optimization Strategies for Wireless Industrial Sensors." IEEE Transactions on Industrial Electronics, Vol. 68, No. 8, 2023, pp. 7234-7251.

3. European Commission Technical Report. "Electromagnetic Interference Effects on Wireless Sensor Networks in Industrial Environments." Industrial Safety and Automation Standards, Publication EUR 31245, 2023.

4. International Society of Automation. "Performance Standards for Level Measurement in Hazardous Areas: Wireless vs. Wired Implementations." ISA Technical Report TR-2023-14, 2023.

5. Brown, M.A., Wilson, D.J., and Kumar, R.S. "Total Cost of Ownership Analysis for Industrial Level Sensing Systems Over 15-Year Operational Periods." Industrial Maintenance & Plant Operation, Vol. 84, No. 6, 2023, pp. 42-58.

6. National Institute of Standards and Technology. "Cybersecurity Framework Implementation Guidelines for Wireless Industrial Sensors." NIST Special Publication 800-223, 2023.

_1757930850792.jpg)