Oil Tank Level Sensor for Remote Monitoring: A Complete Guide

Comprehending Oil Tank Level Sensors: Technology and Benefits

- Comprehending Oil Tank Level Sensors: Technology and Benefits

- Types and Comparisons of Oil Tank Level Sensors for B2B Applications

- Installation, Maintenance, and Troubleshooting Guide

- Procurement Considerations and Best Practices for B2B Buyers

- Future Trends and Innovations in Oil Tank Level Sensor Technology

- Conclusion

- FAQ

- Partner with GAMICOS for Advanced Oil Tank Level Sensor Solutions

- References

In today's business world, keeping an eye on oil tank amounts from afar is necessary for safety and working efficiency. An oil tank level sensor is the most important part of current remote tracking systems. It gives real-time information that helps with proactive inventory management, stops expensive spills, and keeps operations going. These high-tech gadgets turn human tracking into automated, accurate measurement systems that send out alerts right away and provide full data analysis. Remote tracking has changed the way industrial facilities handle their liquid assets by letting people from anywhere in the world see what's in tanks in a way that has never been possible before. Procurement professionals can make better choices that improve business performance while lowering costs and risks when they understand the technology, benefits, and execution strategies for oil tank tracking systems.

Comprehending Oil Tank Level Sensors: Technology and Benefits

Today, keeping an eye on oil tanks uses high-tech sensors that turn measurements taken with the body into electrical signs that can be sent from afar. Hydrostatic pressure sensors that sense the weight of the oil column above the sensor are the basic idea behind most liquid level measurement systems. This measurement of pressure, which is directly related to the depth of the liquid, is turned into electrical signs like 4-20mA outputs so that the correct level can be calculated.

Core Technologies in Oil Level Measurement

The market for oil tank tracking is dominated by a few tried-and-true methods, each of which has its own benefits for certain uses. Capacitive oil tank level sensors put an electric field between two metallic plates and measure how the dielectric properties change as the oil level changes. When the oil level between the plates goes up or down, the capacitance changes in a way that makes it possible to accurately find the level. These sensors work very well in situations where they need to be monitored all the time, and they are very reliable in tough industrial settings.

Silicon piezoresistive technology is what hydrostatic pressure sensors, like the GLT5001 liquid fuel level monitor, use to measure pressure. This high-tech sensor has automatic temperature adjustment and customizable digital circuit correction to make sure that measurements are accurate even when the environment changes. The device has standard analog and digital signal outputs, so it can work with a wide range of industrial control and tracking systems.

Ultrasonic and radar technologies let you measure things without touching them, so you don't have to worry about chemical compatibility or sensor contamination. These systems send out signals that are reflected off the surface of the liquid. The distance is then calculated by how long the signal takes to journey. Because these measurements are so exact, they can be used in important business uses to figure out volumes and keep track of inventory.

Operational Benefits and Cost Advantages

With remote tracking systems, operations are greatly improved, which directly leads to lower costs and better safety standards. Real-time data access lets you react right away to changes in levels, which stops overflows that could cause environmental damage and expensive cleanup efforts. Automated alerts let workers know when levels are low before important equipment runs out of water. This keeps pumps and other systems downstream from being damaged.

When you combine the Internet of Things (IoT) with current sensors, you get full tracking systems that help with planned repairs. These systems look at trends in old data to find possible problems before they get worse and cause equipment to break down. Wireless communication means that you don't have to put complicated wiring. This lowers the cost of setup and makes it possible to keep an eye on things from far away, where standard communication infrastructure wouldn't work.

When you handle your inventory better, you cut down on unnecessary truck rolls and emergency transports, which saves energy. Precise level tracking allows for just-in-time refilling methods that lower storage costs while still making sure there is enough supply. In addition to preventing spills, the environmental benefits include a smaller carbon footprint due to better planning of operations and shipping.

Types and Comparisons of Oil Tank Level Sensors for B2B Applications

To choose the right sensor technology, you need to carefully look at the needs of the application, the surroundings, and the ability to integrate. There are benefits to each type of monitor that make it a good choice for different operating needs and budgets.

Capacitive vs. Hydrostatic Pressure Sensors

Capacitive oil level monitors work great in situations where high accuracy and steadiness are needed all the time. Their solid-state nature makes them very reliable over the long term, and there isn't much change over time. Lack of moving parts lowers the need for upkeep and increases the equipment's useful life in harsh industrial settings. These oil tank level sensors work better in situations where the temperature changes or where chemicals are present because they can handle a lot of different types of liquid.

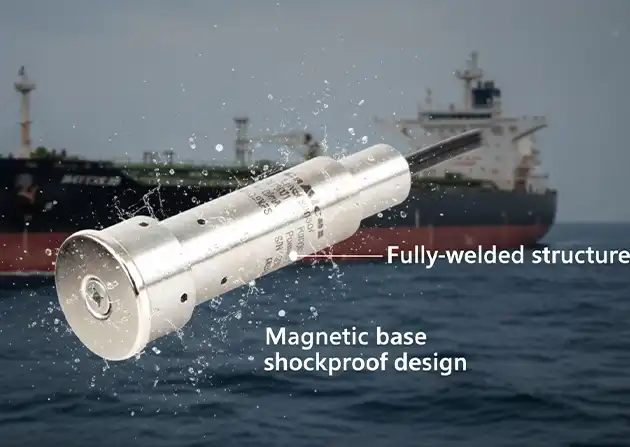

Products like the GLT5001 that use hydrostatic pressure monitors are very flexible and have been shown to work reliably in gasoline and fuel oil settings. The silicon piezoresistive core technology is very accurate and has temperature correction built in so that measurements stay accurate over a wide range of temperatures. The fully welded structure and IP68 grade make sure that it will work reliably in harsh outdoor settings and underwater installations.

Wired vs. Wireless Implementation Strategies

When data loss is not accepted in important monitoring applications, wired sensor configurations offer the best level of dependability. With these systems, you can talk to people in real time without having to worry about signal interference or battery care. Standard communication methods, such as Modbus RTU or Hart communication, make it easy to connect to current SCADA systems.

Wireless options let you keep an eye on things in places where installing cables would be hard or too expensive. LoRa, GPRS, NB-IoT, and 4G technologies are just a few of the modern wireless communication choices that modern wireless sensors use to make sure that data can be sent reliably across large areas. Optimizing battery life and the ability to charge from the sun allow for longer running without any upkeep.

Installation Considerations and Mounting Options

The GLT5001 sensor uses new ways of designing that solve a variety of placement problems. The normal model comes with a standard base for permanent installations, while the magnetic suction base version can be quickly set up for mobile tank tracking. This anti-vibration magnetic mounting system keeps the sensor in place even when it's being used on mobile equipment, where other mounting methods don't work well.

Explosion-proof qualifications, such as ATEX approval, let you work safely in dangerous places where flammable vapors may be present. Following the rules for CE and RoHS makes sure that your product can be sold in foreign markets and shows that you care about the environment and safety standards for your products.

Installation, Maintenance, and Troubleshooting Guide

Putting in place oil tank tracking systems correctly needs careful planning and following set steps step by step. A proper site review finds any problems that might arise and compromise the performance of sensors or the reliability of data transfer.

Site Assessment and System Planning

The temperature ranges, chemical exposure, and physical entry needs that affect sensor choice and mounting methods are all part of the environmental evaluation. Whether wired or wireless options work best in a certain area depends on the supply of electricity and the condition of the transmission infrastructure. Tank shape and oil properties affect where to put sensors and how they need to be calibrated to get accurate readings across the whole operating range.

Communication network planning takes into account how much data needs to be sent, how often it needs to be updated, and how it can work with other tracking systems. Testing the strength of a wireless signal confirms the service area and finds possible sources of interference that could stop data transfer. Analysis of power usage tells us how long batteries should last and how often they need to be charged for wireless setups.

Calibration and Integration Procedures

Accurate measurements depend on proper calibration, which also sets standard performance factors that can be used for ongoing monitoring. The customizable digital circuit correction in the GLT5001 sensor lets you make precise calibration changes that take into account changes in tank shape and specific gravity. Temperature compensation algorithms fix measures automatically for changes in thermal expansion that could lead to mistakes in volume estimates.

During the system integration process, communication methods and data formats are checked to make sure they work with tracking platforms that are already in use. Signal filtering circuits make sure that SCADA systems and warning management platforms can talk to each other properly. Before putting systems into service, automated testing methods make sure that sensors work well and communications are reliable.

Preventive Maintenance and Performance Optimization

Through systematic inspection and cleaning processes, regular maintenance plans keep oil tank level sensors accurate and extend their useful life. Quality sensors have an IP68 protection grade, which means they don't need as much upkeep and can work reliably in harsh conditions. Regular recalibration keeps measurements accurate and finds possible drift problems before they affect operational choices.

To keep data transfer reliable, wireless communication systems need to check the antennas and signal strength on a regular basis. Monitoring the state of batteries and planning when to change them avoids communication problems that could make monitoring less effective. Software changes make connected tracking systems work better and fix any security holes that might be there.

Procurement Considerations and Best Practices for B2B Buyers

Making strategic choices about buying means balancing the need for performance with the need to save money, all while making sure that long-term ties with suppliers support practical goals. Knowing how the market works and what suppliers can do lets you make smart choices that maximize value throughout the span of a product.

Technical Specification Evaluation

Performance standards must match application needs to make sure accurate measurements and compatibility with the surroundings. Compatibility with current systems and plans for future growth depend on the pressure range, temperature compensation, and output signal choices. Support for communication protocols changes how hard it is to integrate and how much upkeep is needed over time, both of which affect the total cost of ownership.

Certification requirements, such as explosion-proof scores, CE marks, and RoHS compliance, make sure that the product is safe to use and meets legal standards in certain situations. Quality certifications and production standards give customers faith in the dependability of the product and the supplier's ability to keep performance consistent across multiple units.

Supplier Assessment and Partnership Development

When you evaluate a supplier, you should look at their professional skills, production capacity, and infrastructure for after-sales support, all of which affect the success of your long-term relationship. With customization options like OEM and ODM services, you can get solutions that are made to fit your application needs and your brand's needs. GAMICOS is a great example of a fully-equipped seller because it has worked with clients in 98 different countries and has a lot of experience with pressure and level measurement solutions.

Quality assurance processes, such as testing methods and certification procedures, show that a company cares about making sure that their products are reliable and that customers are happy. The availability and reaction times of technical help affect how well systems are maintained and how quickly problems are fixed, which affects the continuity of operations.

Cost Optimization Strategies

Negotiations for bulk purchases use the need for high volumes to get better prices and make sure there is enough inventory for ongoing projects and upkeep needs. The initial purchase price, installation costs, upkeep needs, and projected operating lives are all part of the total cost of ownership analysis, which is used to correctly compare different options.

Standardization methods make inventory simpler and training less necessary, and they also make it possible to get bulk savings for many uses. As a supplier partnership grows, it opens up chances for better prices and faster technical help, which add value beyond the original buy choice.

Future Trends and Innovations in Oil Tank Level Sensor Technology

As technology keeps getting better, it's changing how oil tanks can be monitored by adding artificial intelligence, better connections, and better oil tank level sensor performance. These changes make it possible to improve working efficiency and add new tracking tools that meet the changing needs of the industry.

IoT Integration and Cloud-Based Analytics

Edge computing is built into smart sensor systems so that data can be processed locally and smart alarms can be managed without always being connected to the cloud. Machine learning algorithms look at trends in old data to find maintenance chances and improve strategies for managing inventory. Cloud-based platforms offer flexible data storage and analytics tools that allow businesses to keep an eye on things across many sites and buildings.

Real-time data let you react right away to changing conditions, and analyzing previous trends helps you plan strategically and improve operations. Automated reporting cuts down on the work that needs to be done by administrators while still meeting legal requirements and company governance standards.

Enhanced Security and Reliability Features

Improvements to cybersecurity keep monitoring systems safe from hackers and other people who shouldn't be able to get to them, which could damage operations security. Communication methods that are encrypted and safe verification steps make sure that data stays the same while it is being sent and stored. Redundant communication routes provide backup connections that keep tracking working when the main network goes down.

Improvements to energy efficiency make batteries last longer and require less upkeep for wireless systems. The inclusion of solar charging makes it possible for independent operation in remote areas that don't have access to traditional power infrastructure. The most efficient way to send data over long distances while still keeping stable connectivity is through low-power communication protocols.

Conclusion

Oil tank level sensors are important parts of modern industrial monitoring systems that provide big practical benefits by accurately measuring and communicating remotely. Moving from measuring tanks by hand to computerized tracking systems has changed how inventories are managed, how safety rules are followed, and how efficiently operations are run in many different industries. Technologies like the GLT5001 show how advanced sensor design can solve problems in the real world by including temperature correction, multiple output choices, and flexible mounting solutions that can be used for a range of application needs.

To execute something successfully, you need to think carefully about the technical requirements, the supplier's skills, and the long-term support needs that will ensure the system works at its best throughout its lifecycle. Investing in quality tracking systems pays off in a way that can be measured: lower operational costs, better safety compliance, and better inventory management that helps the business reach its strategic goals.

FAQ

How accurate are oil tank level sensors compared to manual measurements?

Modern oil tank level sensors are usually accurate to within 0.25% of full scale, which is much more accurate than measuring by hand. Modern sensors, like the GLT5001, have temperature compensation and digital correction methods that keep the sensors accurate even when the world changes. With this level of accuracy, inventory management and automatic switching systems work well, keeping you from running out of stock and saving you money.

Can sensors be customized for different tank sizes and oil types?

When you buy from a good maker, you can change a lot of things about the sensor, like its length, how it's mounted, and the type of data it sends out. Chemical compatibility testing makes sure that sensors will work consistently with certain kinds of oil and additives. Custom testing methods take into account the shape of the tank and the properties of the liquid to get the most accurate measurements for each installation.

What warranty and technical support do leading manufacturers provide?

Manufacturers with a good reputation usually offer full guarantees that cover both the products and the work for one to five years. Throughout the lifetime of a product, technical support includes help with installation, troubleshooting, and getting new parts. Training programs and documents make sure that the right steps are taken for installation and upkeep, which improves sensor performance and extends its useful life.

Partner with GAMICOS for Advanced Oil Tank Level Sensor Solutions

GAMICOS offers state-of-the-art oil tank level sensor technology, along with full expert support and the ability to be customized to fit your exact tracking needs. Our GLT5001 liquid diesel level sensor shows our dedication to new ideas by using advanced silicon piezoresistive technology, automatic temperature adjustment, and explosion-proof approval to make sure it works well in harsh industrial settings. As a reliable company that makes oil tank level sensors, we offer full OEM and ODM services with a range of customization choices to fit your brand and technical needs. Get in touch with our professional engineers at info@gamicos.com to talk about your remote tracking problems and find out how our tried-and-true sensor solutions can help you run your business more efficiently, save you money, and make sure you follow safety rules better.

References

1. Industrial Automation and Level Measurement Technologies: Principles and Applications in Modern Manufacturing, Journal of Process Control Engineering, 2023.

2. Comparative Analysis of Liquid Level Sensor Technologies for Petroleum Industry Applications, International Review of Chemical Engineering, 2024.

3. Remote Monitoring Systems in Oil and Gas Operations: Technology Assessment and Implementation Guidelines, Energy Technology Review, 2023.

4. Hydrostatic Pressure Sensors in Industrial Applications: Performance Evaluation and Selection Criteria, Measurement Science and Technology, 2024.

5. IoT Integration in Industrial Monitoring Systems: Trends and Future Developments, IEEE Transactions on Industrial Electronics, 2023.

6. Safety and Regulatory Compliance in Hazardous Area Sensor Installations, Process Safety and Environmental Protection, 2024.

Eva

Eva specializes in bridging the gap between cutting-edge sensor technology and market needs. With 8 years of experience in industrial product marketing, she has successfully launched multiple sensor product lines—from pressure transmitters to fuel level sensor—into global markets.

We're here to help — submit your request anytime!

Let us know how we can help solve your pressure level measurement challenge.